Coating structure on equipment for producing leather products

A technology for leather goods and equipment, applied in the direction of spraying device, liquid spraying device, etc., can solve the problems of uneven spraying, leather goods wrinkling, affecting the appearance and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

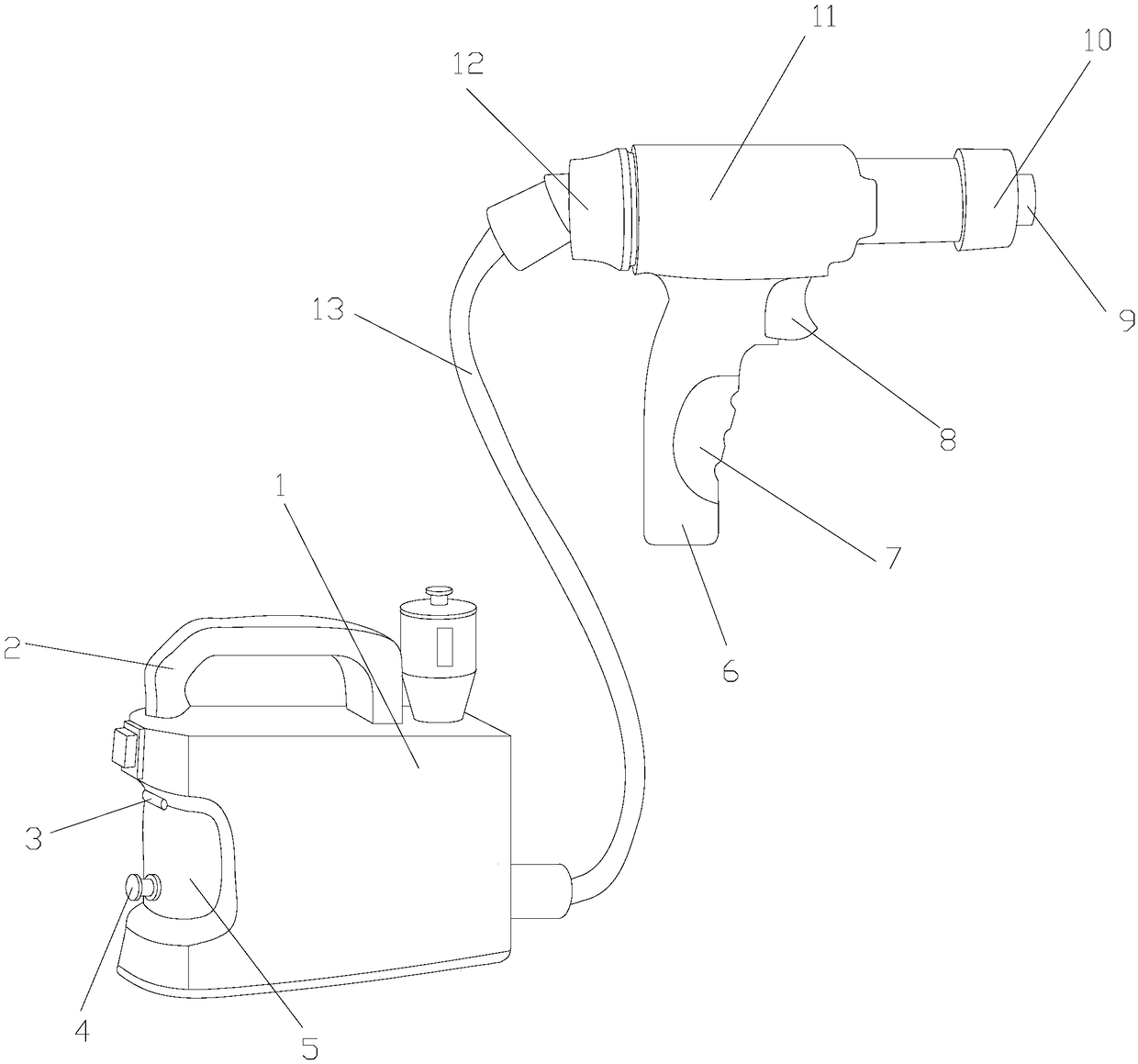

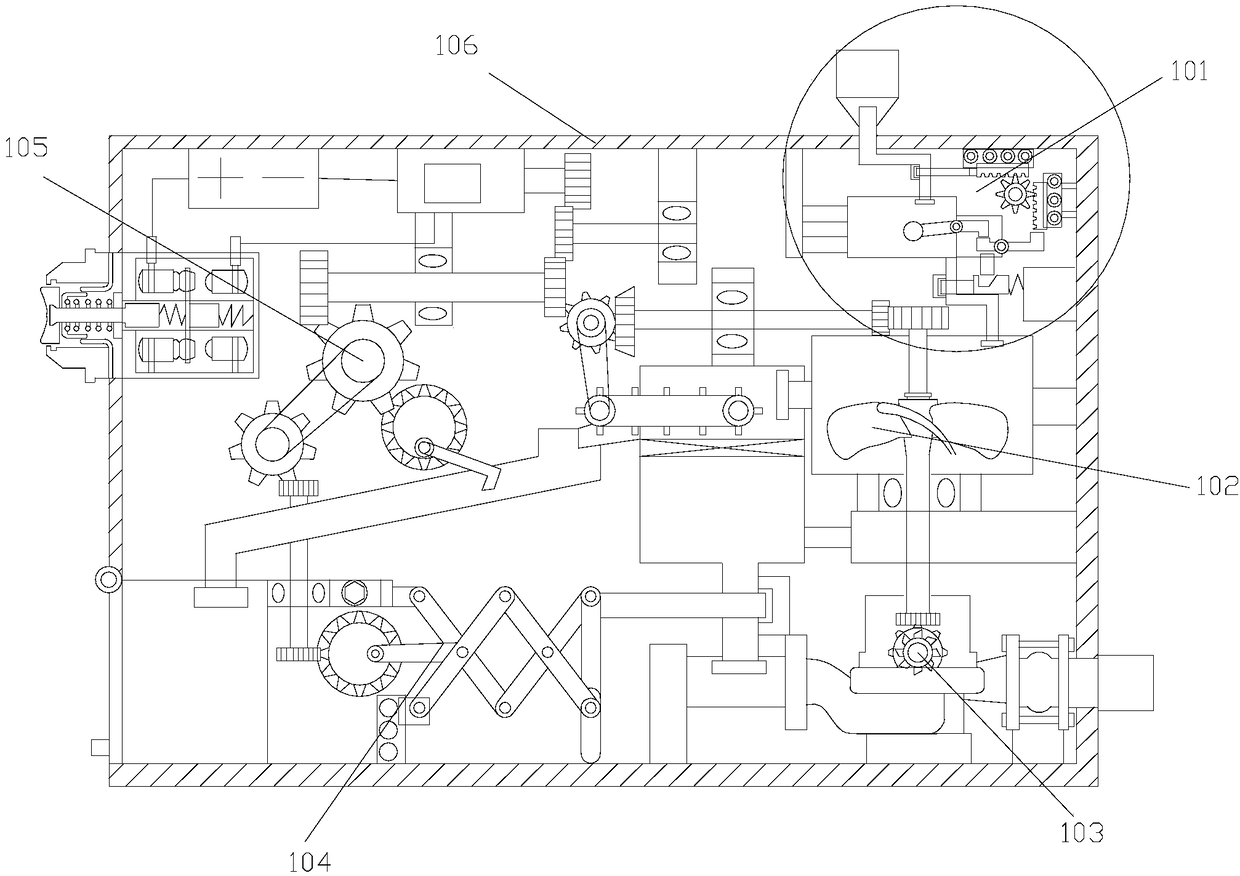

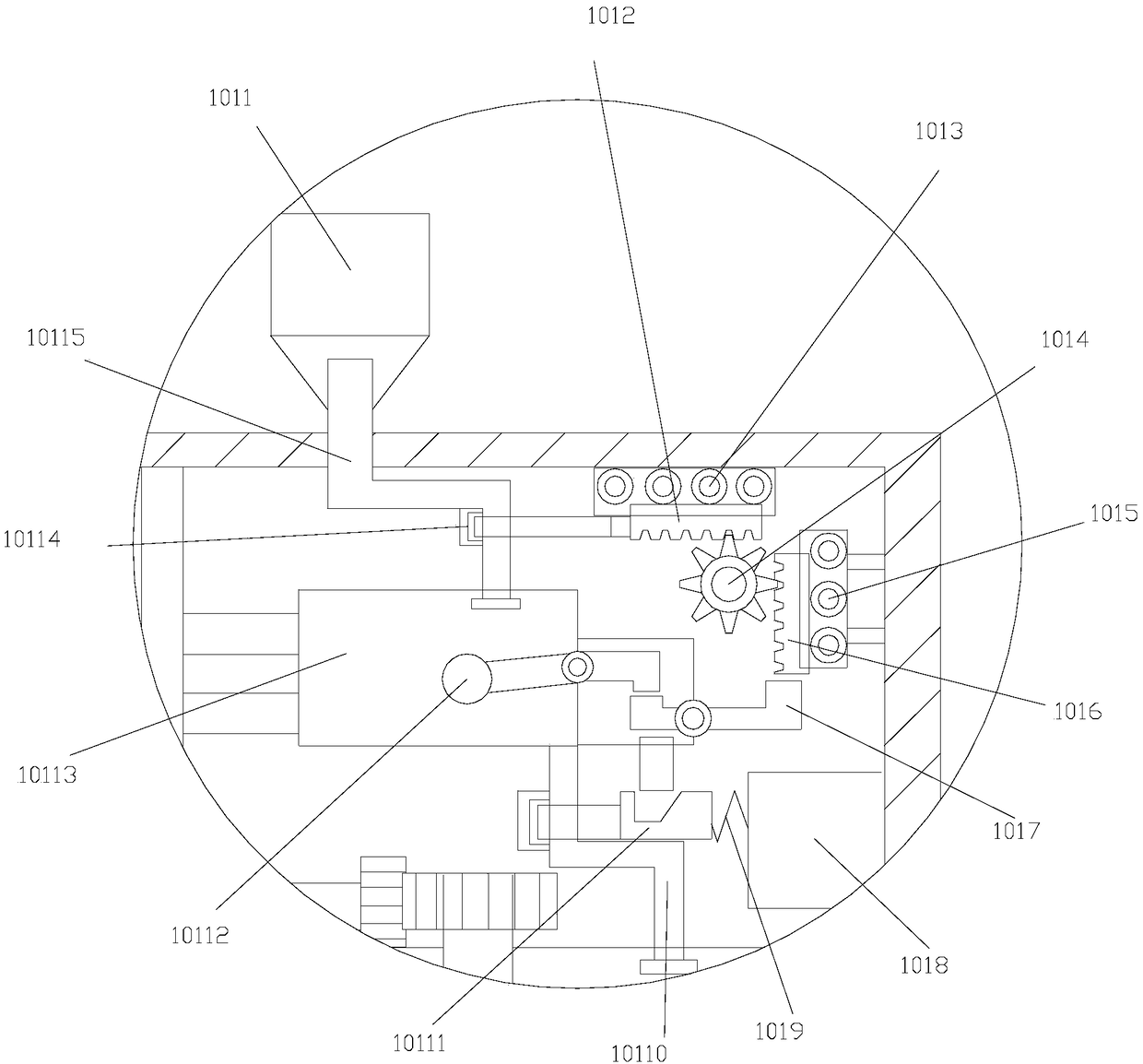

[0025] See Figure 1-Figure 5 , The present invention provides a technical solution for coating structure on equipment for producing leather leather goods: its structure includes spraying device 1, handle 2, hinge 3, ring handle 4, box door 5, handle 6, and anti-skid pad 7. , Switch button 8, spray head 9, spray head fixing seat 10, spray gun 11, hose connection seat 12, hose 13, the bottom of the handle 2 and the top of the spraying device 1 are fixedly connected by screws, and the right end of the box door 5 is connected to the hinge 3. The inner ring is welded, the right end of the box door 5 is attached to the left end of the spraying device 1, the top of the handle 6 and the bottom of the spray gun 11 are an integrated structure, the right end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com