Sealing type high voltage resisting electric connector

An electrical connector, sealed technology, applied in the direction of connection and connection device components, circuits, etc., can solve the problems of defective environmental adaptation, complex internal structure, unstable voltage resistance, etc., to meet the requirements of space environment use, Excellent environmental resistance, good use and maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

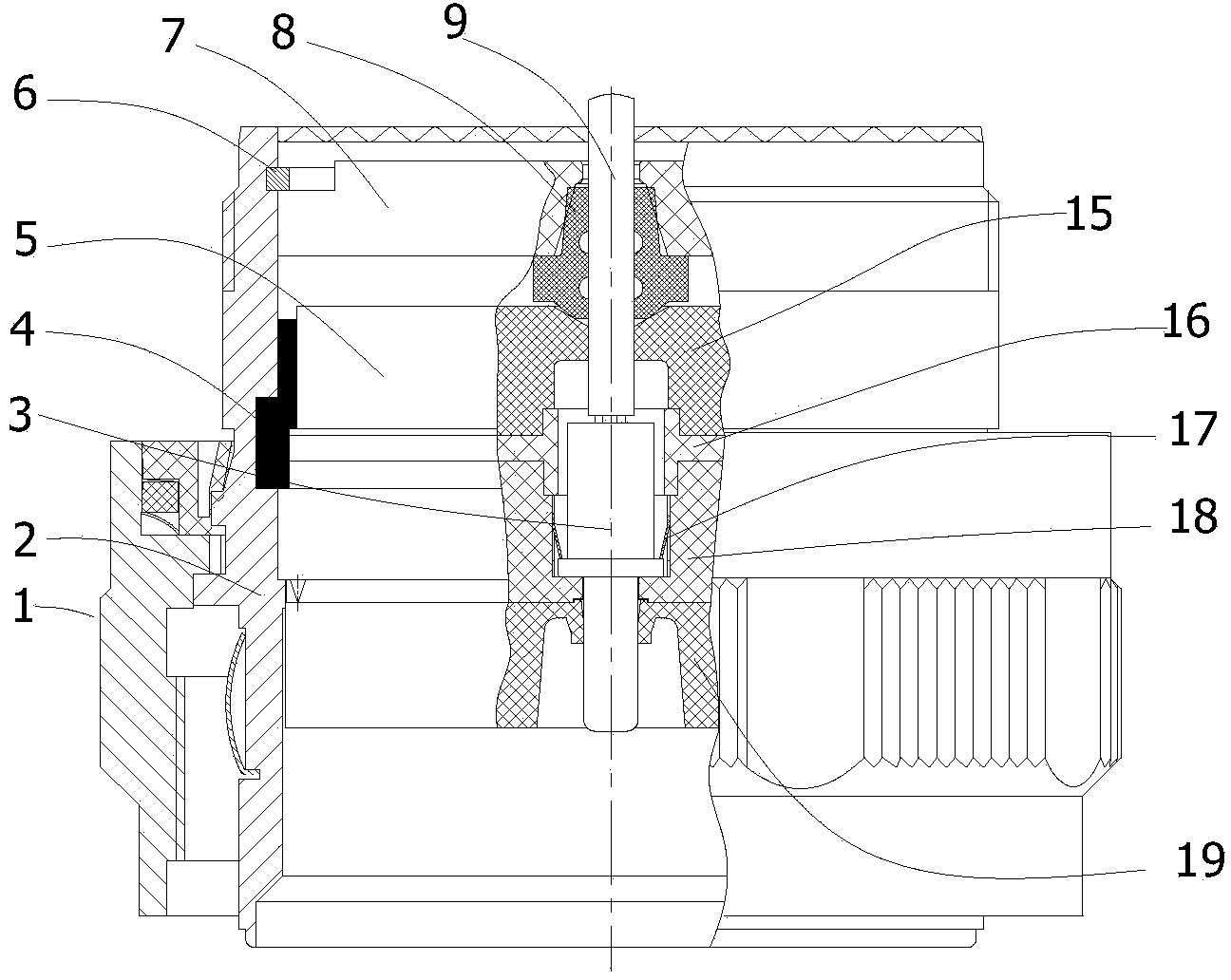

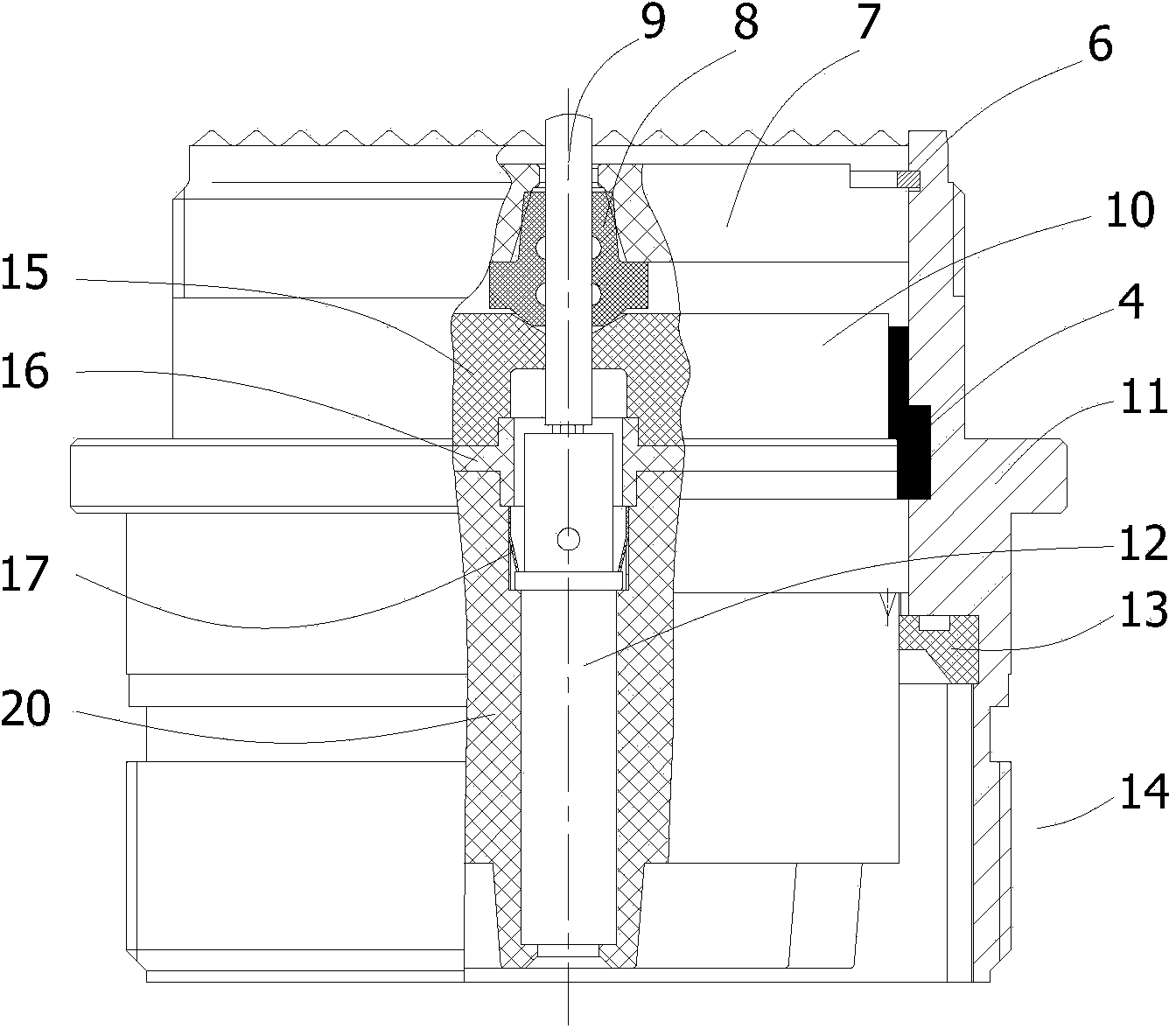

[0052] The embodiments of the sealed high-voltage electrical connector according to the present invention will be described in detail below with reference to the accompanying drawings:

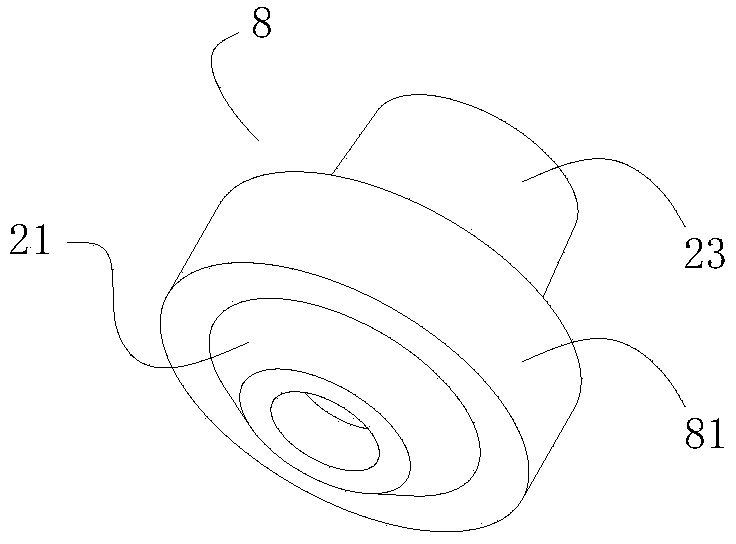

[0053] like figure 1 It is a schematic structural diagram of an embodiment of the plug (1) of the sealed high-voltage electrical connector according to the present invention. In this embodiment, the plug (1) includes a plug housing (2), an interface gasket (19), a pin mounting assembly (5), a pin contact (3), an elastic claw (17), and a wire sealing body (15), a sealing sleeve (8), a cover plate (7), an opening retaining ring (6), and a wire (9). The pin mounting assembly (5) includes an upper insulating mounting plate (18) and a lower insulating mounting plate (16) for the pins. The pin mounting assembly (5) is arranged in the plug housing (2), and is limited by the step of the inner hole of the plug housing (2) in the mating direction of the plug (1), and the rear end is limited by the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com