Anticorrosive paint and preparation method thereof

An anti-corrosion coating, aniline monomer technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as environmental protection and poor environmental resistance, and achieve low production costs, reduced coating thickness, and reduced organic content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

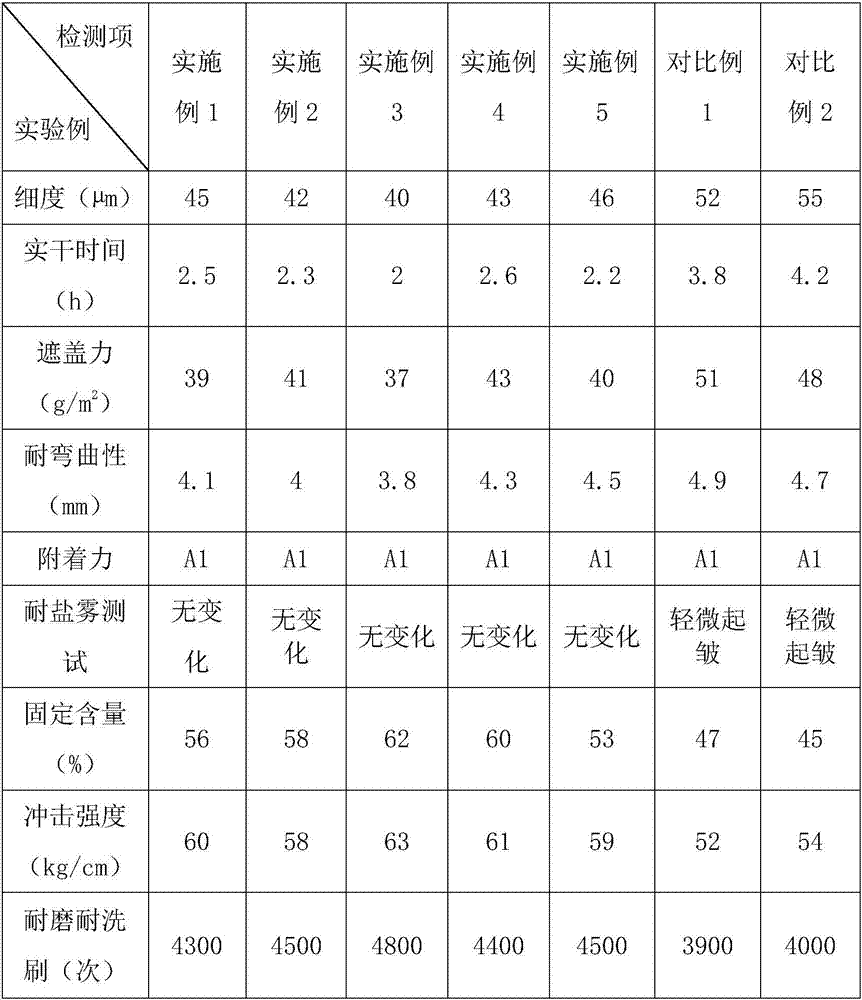

Examples

Embodiment 1

[0022] (1) Take by weighing 10g natural graphite powder, place in 1000ml reaction bottle, add 1g calcium nitrate and 5g potassium nitrate wherein, after stirring, slowly add 120g deionized water dropwise in reaction bottle, continue to stir, then add again Slowly add 2g of 98% concentrated sulfuric acid in the reaction bottle, and obtain the graphene solution after 1 hour of reaction;

[0023] (2) Take 500ml of the graphene solution, add 12g of phosphate, 20g of silicon dioxide, and 8g of aniline monomer into it, stir for 40min, then continue to add 20g of benzenesulfonic acid, continue to stir, and react at 25-30°C 5-8h, after the reaction is over, centrifuge, wash, and dry to remove the solution in the reaction suspension, and then grind and pass through a 150-mesh sieve to obtain a composite powder;

[0024] (3) 35g of the composite powder, 1.5g of filler, 5.5g of epoxy resin, 8g of organic solvent and 80ml of deionized water were mixed and fully stirred to obtain a slurry,...

Embodiment 2

[0026] (1) Take by weighing 10g natural graphite powder, place in 1000ml reaction bottle, add 1g calcium nitrate and 4g potassium nitrate wherein, after stirring evenly, in reaction bottle, slowly add 100g deionized water dropwise, continue to stir, then add again The mass concentration of 0.5g is slowly added dropwise in the reaction flask and is 98% concentrated sulfuric acid, and the graphene solution is obtained after 1 hour of reaction;

[0027] (2) Take 600ml of the graphene solution, add 9g of phosphate, 12g of silicon dioxide, and 6g of aniline monomer into it, stir for 40min, then continue to add 15g of benzenesulfonic acid, continue to stir, and react at 25-30°C 5-8h, after the reaction is over, centrifuge, wash, and dry to remove the solution in the reaction suspension, and then grind and pass through a 250-mesh sieve to obtain a composite powder;

[0028] (3) 35g of the composite powder, 1.3g of filler, 4g of epoxy resin, 6g of organic solvent and 85ml of deionized...

Embodiment 3

[0030] (1) Take by weighing 10g natural graphite powder, place in 1000ml reaction bottle, add 2g calcium nitrate and 4g potassium nitrate wherein, after stirring, slowly add 200g deionized water dropwise in reaction bottle, continue to stir, then add again Slowly add 1 g of concentrated sulfuric acid with a mass concentration of 98% in the reaction bottle, and obtain the graphene solution after 1 hour of reaction;

[0031] (2) Take 570ml of the graphene solution, add 16g of phosphate, 10g of silicon dioxide, and 12g of aniline monomer into it, stir for 40min, then continue to add 20g of benzenesulfonic acid, continue to stir, and react at 25-30°C 5-8h, after the reaction is over, centrifuge, wash, and dry to remove the solution in the reaction suspension, and then grind and pass through a 220-mesh sieve to obtain a composite powder;

[0032] (3) 27g of the composite powder, 2.2g of filler, 3.7g of epoxy resin, 7g of organic solvent and 70ml of deionized water were mixed and fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com