A kind of modified acrylate pressure-sensitive adhesive prepolymer and its preparation method and application

A technology of acrylate and butyl acrylate, applied in the field of modified acrylate pressure-sensitive adhesive prepolymer and its preparation, can solve the problems of corrosion of substrates, low cost and energy consumption, residual glue, etc., and achieves environmental resistance Good properties, fast curing speed and excellent peeling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

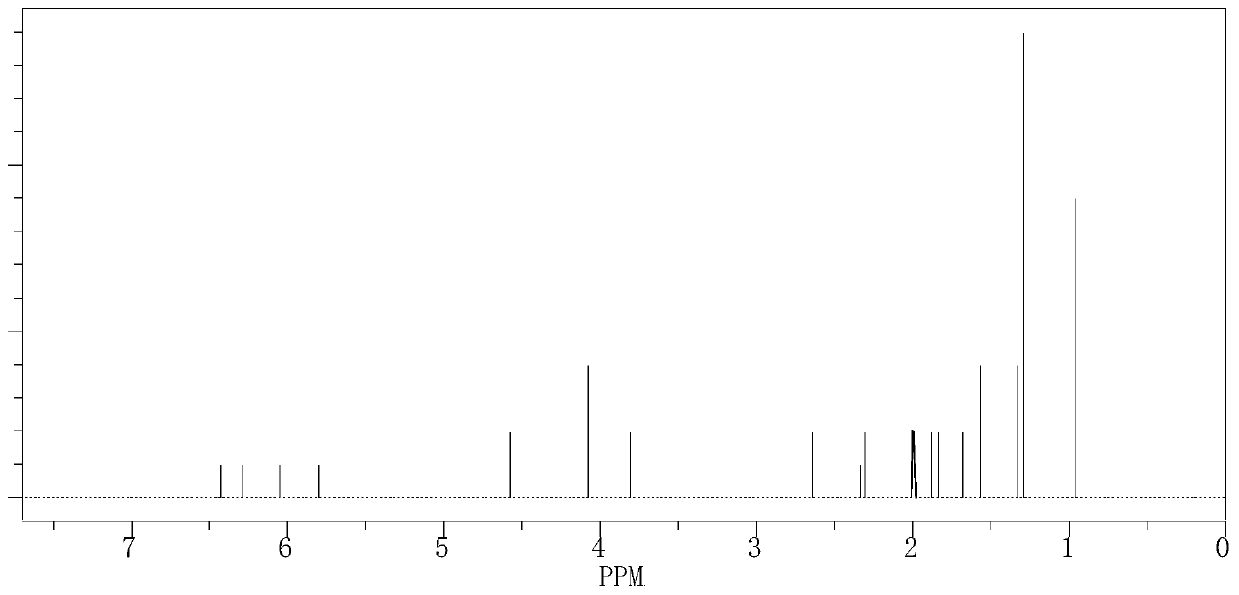

Image

Examples

preparation example Construction

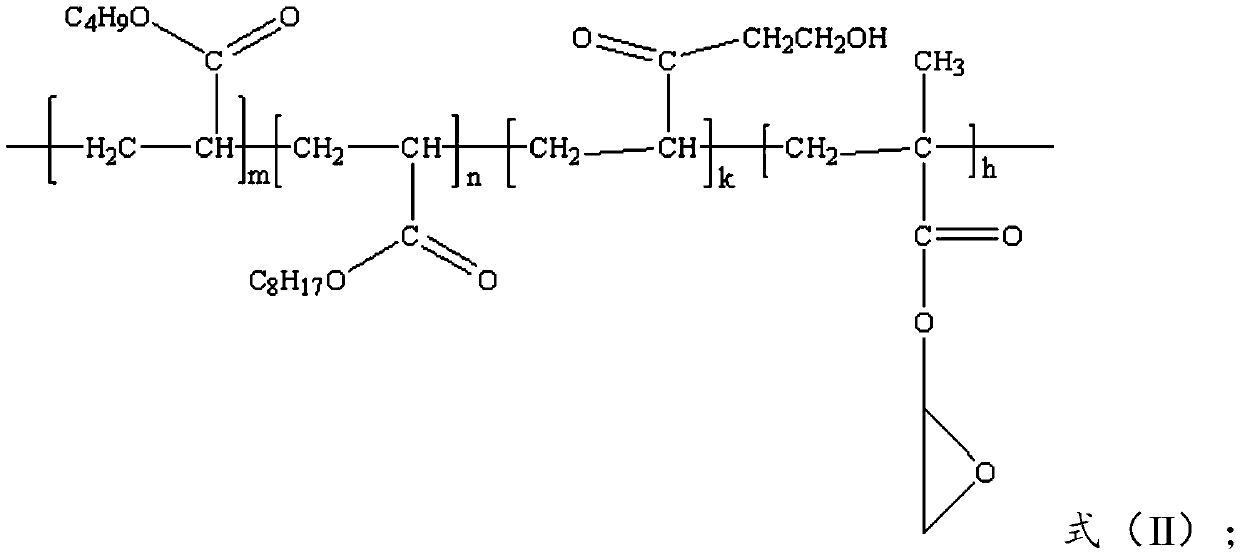

[0039] The present invention also provides a preparation method of a modified acrylate pressure-sensitive adhesive prepolymer, comprising the following steps:

[0040] a) Mix butyl acrylate, isooctyl acrylate, hydroxyethyl acrylate, glycidyl methacrylate, solvent and thermal initiator to obtain a reaction raw material mixture; the thermal initiator is selected from azobisisobutyronitrile , benzoyl peroxide or di-tert-butyl peroxide;

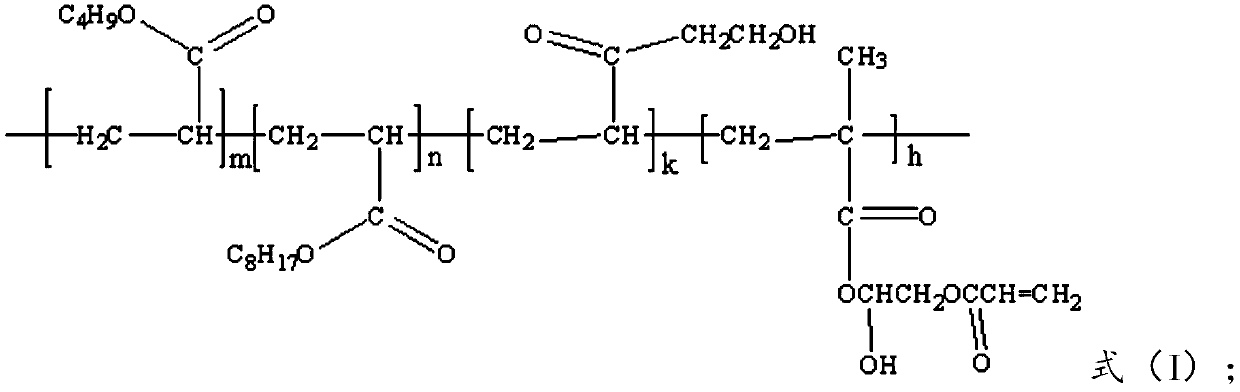

[0041] b) performing a prepolymerization reaction on the reaction raw material mixture obtained in step a), and then performing a polymerization reaction to obtain a reaction product of the structure shown in formula (II);

[0042]

[0043] c) reacting the reaction product obtained in step b) with acrylic acid, a catalyst and a polymerization inhibitor, then adding a diluent and carrying out vacuum distillation to obtain a modified acrylic pressure-sensitive adhesive prepolymer having a structure shown in formula (I) ; The diluent is selected...

Embodiment 1

[0082] (1) Add 30g butyl acrylate, 50g isooctyl acrylate, 10g hydroxyethyl acrylate, 10g glycidyl methacrylate, 100g A mixed solvent of toluene and ethyl acetate (1:1) and 0.8 g of azobisisobutyronitrile (AIBN) were mixed uniformly to obtain 195 g of reaction raw material mixture;

[0083] (2) Take one-third of the above-mentioned reaction raw material mixture and add it to the reaction kettle, turn on the stirring, raise the temperature to 80°C for 1.5h, then add one-third of the above-mentioned reaction raw material mixture, and react at the same temperature 1.5h, then add the remaining one-third of the above-mentioned reaction raw material mixture, react at the same temperature for 1.5h, adjust the temperature to 105°C for 8h after the reaction, and obtain the reaction product of the structure shown in formula (II);

[0084]

[0085] (3) Cool to room temperature, protect with nitrogen, then add 3.1g of acrylic acid, 0.1g of catalyst triphenylphosphine, 0.03g of polymeriz...

Embodiment 2

[0090] (1) Add 30g butyl acrylate, 50g isooctyl acrylate, 10g hydroxyethyl acrylate, 10g glycidyl methacrylate, 100g A mixed solvent of toluene and ethyl acetate (1:1) and 0.8 g of benzoyl peroxide (BPO) were mixed uniformly to obtain 196 g of reaction raw material mixture;

[0091] (2) Take one-third of the above-mentioned reaction raw material mixture and add it to the reaction kettle, turn on the stirring, raise the temperature to 90°C for 1.5h, then add one-third of the above-mentioned reaction raw material mixture, and react at the same temperature 1.5h, then add the remaining one-third of the above-mentioned reaction raw material mixture, react at the same temperature for 1.5h, adjust the temperature to 100°C for 8h after the reaction, and obtain the reaction product of the structure shown in formula (II);

[0092] (3) Cool to room temperature, protect with nitrogen, then add 3.1g of acrylic acid, 0.1g of catalyst tertiary amine (hexamethylenetetramine), 0.03g of polymer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com