Method for manufacturing sound boundary wave apparatus, and sound boundary wave apparatus

A manufacturing method and interface wave technology, applied in semiconductor devices, electrical components, impedance networks, etc., can solve problems such as moisture intrusion, and achieve excellent environmental resistance characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

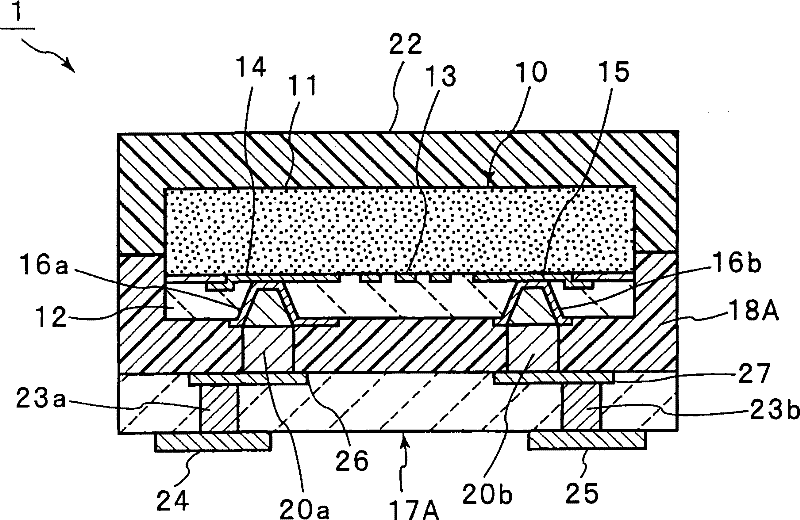

[0051] Hereinafter, the present invention will be clarified by describing specific embodiments of the present invention with reference to the drawings.

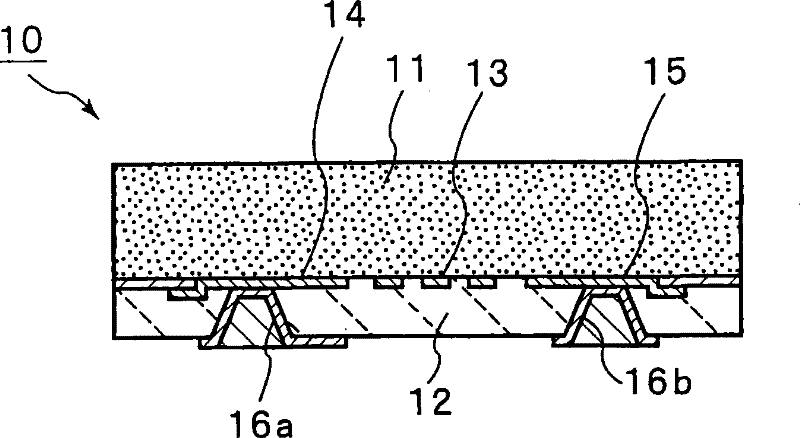

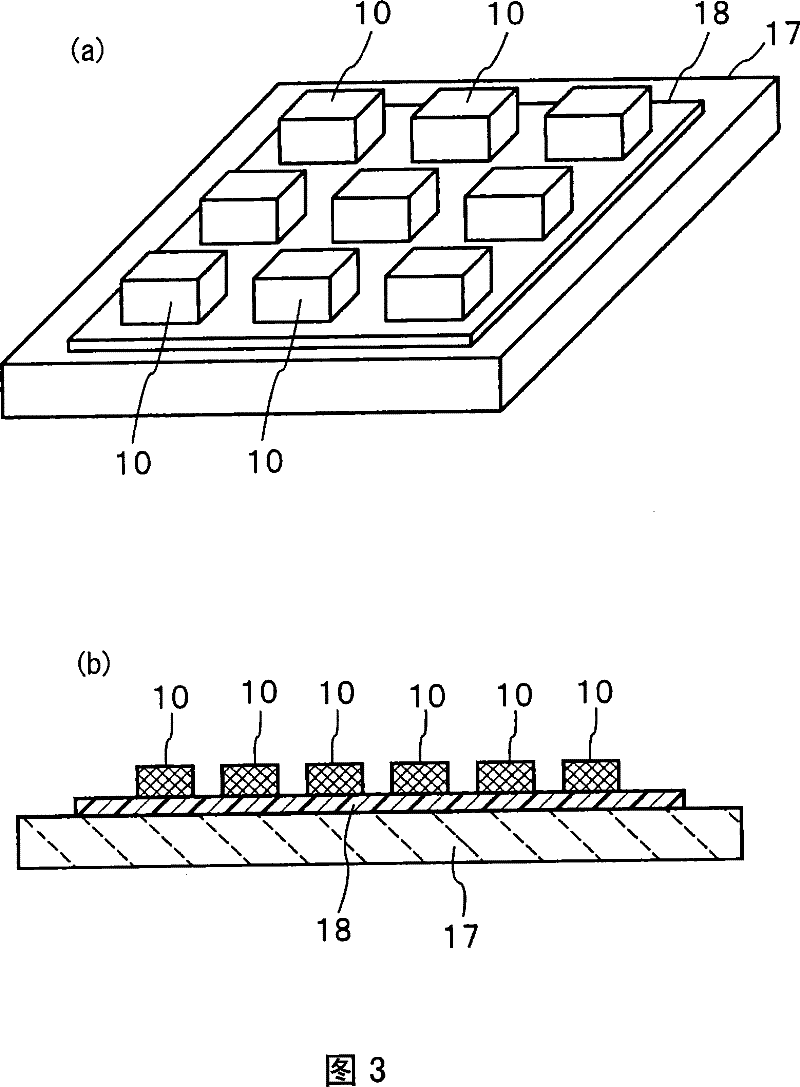

[0052] refer to Figure 1 ~ Figure 1 5. A method of manufacturing the boundary acoustic wave device according to the first embodiment of the present invention will be described.

[0053] first, prepare figure 2 The boundary acoustic wave element 10 is shown. The boundary acoustic wave element 10 has a structure in which a first dielectric layer 11 and a second dielectric layer 12 are laminated. In this embodiment, the first intermediary layer 11 is made of LiNbO 3 Piezoelectric single crystal substrates such as single crystal substrates. In addition, the first medium 11 may be formed of a piezoelectric material other than a piezoelectric single crystal.

[0054] In this embodiment, the second medium 12 is made of SiO 2 film formation, but the second medium 12 can also be made of SiO 2 Other dielectrics or insulators. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com