High-strength micro optical fiber cable and manufacturing method thereof

A high-strength, optical cable technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of reducing initial investment, low utilization rate, and high investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

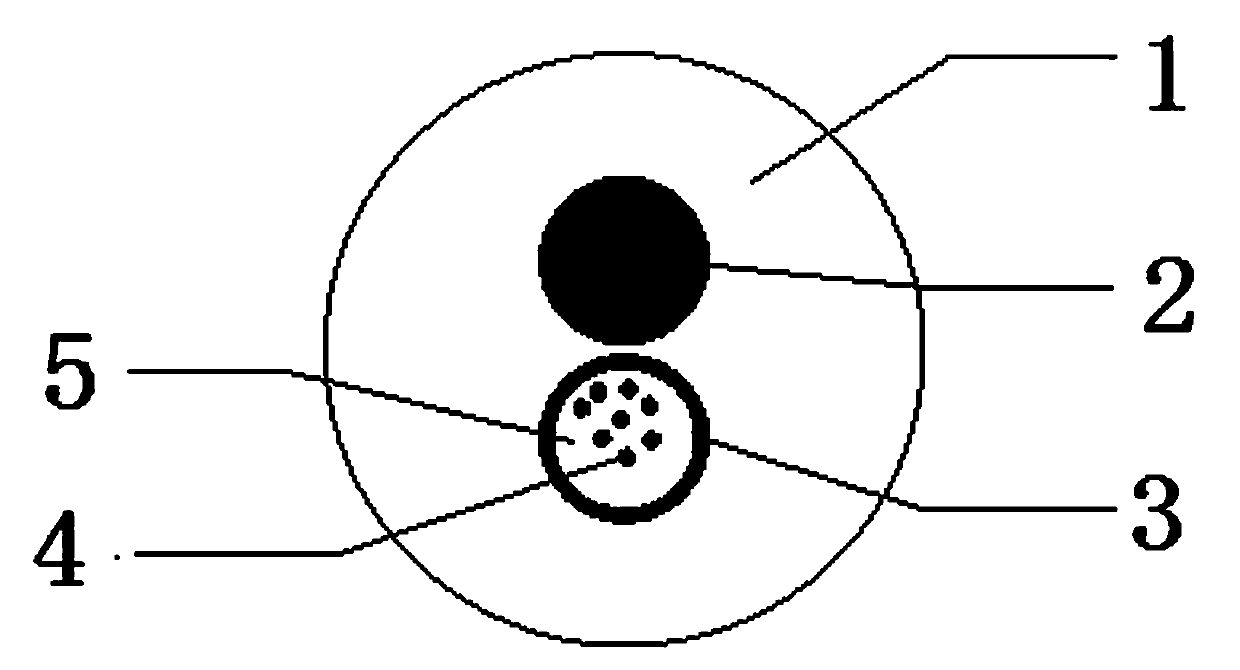

[0020] Refer to attached figure 1 , a high-strength micro-optical cable, including a stainless steel tube 3 light unit for protecting the optical fiber 4, a strength member 2 (phosphating steel wire or glass fiber reinforced resin) to strengthen the optical cable, and a sheath 1 for protecting the optical cable The optical unit of the stainless steel tube 3 and the reinforcing member 2 cover the sheath 1, and the optical unit of the stainless steel tube 3 is provided with several optical fibers 4 for transmitting optical signals.

[0021] Preferably, the stainless steel tube 3 optical unit includes a steel tube coated on the outer layer, a number of optical fibers 4 for transmitting optical signals and an optical fiber ointment 5 for fixing the position of the optical fiber 4, and the number of optical fibers 4 is 4 ~24 pieces, the outer diameter of the stainless st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com