Nanofiber/glass fiber composite filter material prepared by a kind of electrospinning method and the same

A glass fiber and nanofiber technology, applied in the field of electrospinning, can solve problems such as electric field interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

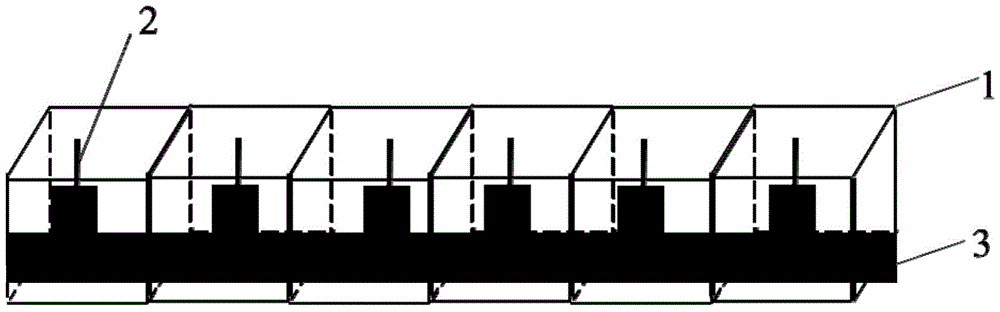

[0071] An electrospinning method is multi-needle electrospinning, and the needles of the multi-needle electrospinning are insulated. figure 1 It is a schematic diagram of the electrospinning needle isolation device, in which, 1 is an insulating material partition, 2 is a spinneret device, and 3 is a spinneret base; the needles share the same insulating bottom plate; the insulation between the needles refers to the use of insulating materials for each needle. Anti-interference isolation treatment; specifically, there is an insulating material around the needle to form an isolation groove, the shape of the isolation groove is square, and the depth of the isolation groove is 1 times the length of the needle; the insulating material is styrene-butadiene-acrylonitrile copolymer things.

Embodiment 2

[0073] An electrospinning method is multi-needle electrospinning, and the needles of the multi-needle electrospinning are insulated. Among them, the needles share the same insulating base plate; the insulation between the needles refers to the use of insulating materials to carry out anti-interference isolation treatment for each needle; specifically, there are insulating materials around the needles to form isolation grooves, and the shape of the isolation grooves is circular. The depth of the groove is 3 times the length of the needle; the insulation material is polycarbonate.

Embodiment 3

[0075] An electrospinning method is multi-needle electrospinning, and the needles of the multi-needle electrospinning are insulated.

[0076] The specific steps are:

[0077] (1) adding inorganic nanoparticles, silicon dioxide nanoparticles into the solvent N,N-dimethylformamide, and ultrasonically dispersing for 30 minutes to obtain a dispersion liquid in which the nanoparticles are uniformly dispersed;

[0078](2) The polymer polyacrylonitrile is added to the dispersion liquid, and magnetically stirred for 8 hours to prepare a uniform and stable spinning solution, wherein the mass fraction of polyacrylonitrile is 9%, and the amount of inorganic nanoparticles added is and 10% of the total mass of inorganic nanoparticles;

[0079] (3) The spinning solution is subjected to multi-needle electrospinning. The process conditions of multi-needle electrospinning are: power supply voltage 50KV, spinning environmental conditions are temperature 35°C, relative humidity 25%, spinning so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| piezoresistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com