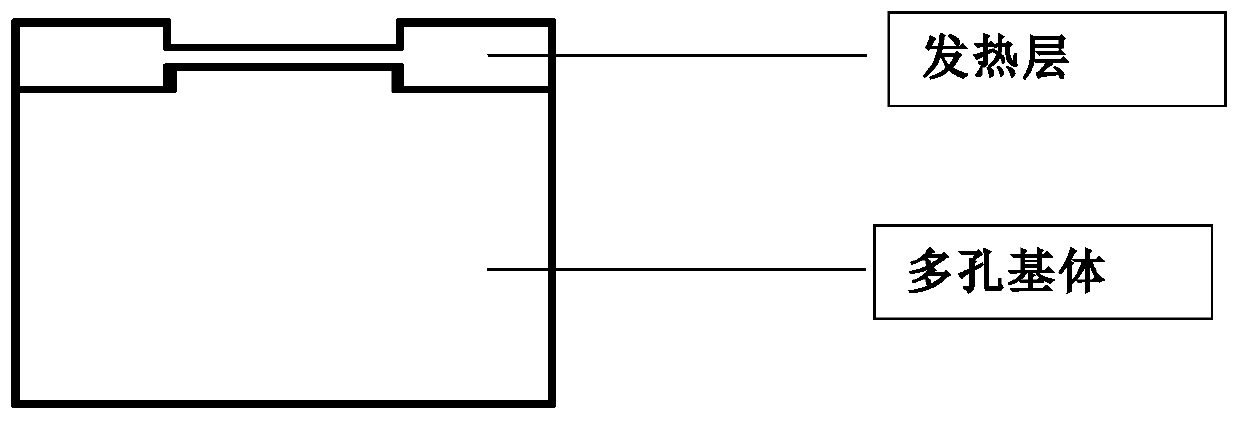

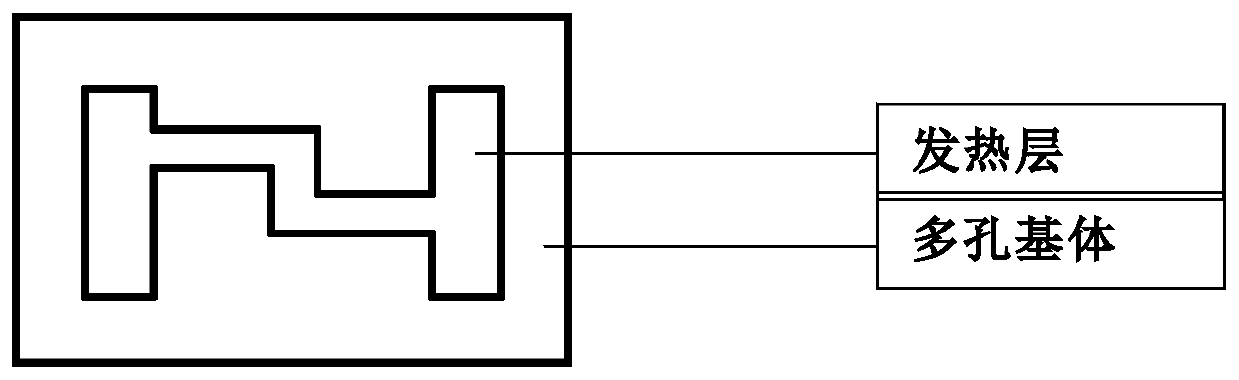

Preparation method of porous titanium-based drug atomization core and heating component for atomization

A technology of heating components and atomizing cores, which is applied in the direction of medical devices, nebulizers for treatment, and other medical devices. The effect of cost and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A porous titanium-based drug atomization core and a heating element for atomization are prepared. Prepare as follows:

[0038] (1) The purity is 90%, and the particle size is 50 μ m industrial titanium powder, adhesive is mixed and stirred evenly according to a certain ratio as the porous matrix raw material for subsequent use, denoted as a, wherein titanium powder accounts for 55wt%, and adhesive accounts for 45wt% , the binder is composed of paraffin wax: polypropylene: stearic acid = 65:30:5 (m:m:m) system; then mix nickel-chromium alloy powder, methyl cellulose (MC) and deionized water evenly, Denoted as b, wherein the mass ratio of nickel-chromium alloy powder to methyl cellulose (MC) is 10:1, and deionized water is added to make the solid content of b raw material 60wt%. Put the raw materials of a and b into the planetary ball mill for mixing, wherein the ball-to-material ratio is 4:1, the diameter of the corundum ball is 1-5mm, the ball milling speed is 150r / min...

Embodiment 2

[0044] A porous titanium-based drug atomization core and a heating element for atomization are prepared. Prepare as follows:

[0045] (1) The industrial titanium alloy powder with a purity of 95% and a particle size of 80 μm, an adhesive and deionized water are mixed and stirred evenly according to a certain proportion and used as a raw material of a porous matrix for later use, which is recorded as a. Among them, the titanium-titanium alloy powder accounts for 85wt%, and the binder accounts for 15wt%. The binder is composed of methylcellulose:polyethylene glycol=1:1 system, and the solid content is 80wt.%. Then mix nickel-chromium alloy powder, methyl cellulose (MC) and deionized water evenly, denoted as b, wherein the mass ratio of nickel-chromium alloy powder to methyl cellulose (MC) is 18:1, and then add deionized The water was such that the solids content of the b material was 75% by weight. Put the raw materials of a and b into the planetary ball mill for mixing, where...

Embodiment 3

[0051] A porous titanium-based drug atomization core and a heating element for atomization are prepared. Prepare as follows:

[0052] (1) Stir the industrial titanium alloy TC4 powder with a purity of 92% and a particle size of 120 μm, a binder and deionized water according to a certain ratio and use it as a solid phase raw material for later use, denoted as a, wherein the binder is methyl The mass ratio of cellulose, titanium powder and binder is 90:10, and the solid content of raw material a is 90%; then the nickel-chromium-iron alloy powder, methyl cellulose and deionized water are mixed evenly, and it is recorded as b, wherein nickel The mass ratio of ferrochrome alloy powder to methyl cellulose is 9:1, and deionized water is added to make the solid content of b to be 80%. Put the a and b slurries into the planetary ball mill respectively for mixing, wherein the ball-to-material ratio is 4:1, the diameter of the corundum ball is 1-5mm, the ball milling speed is 100r / min, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com