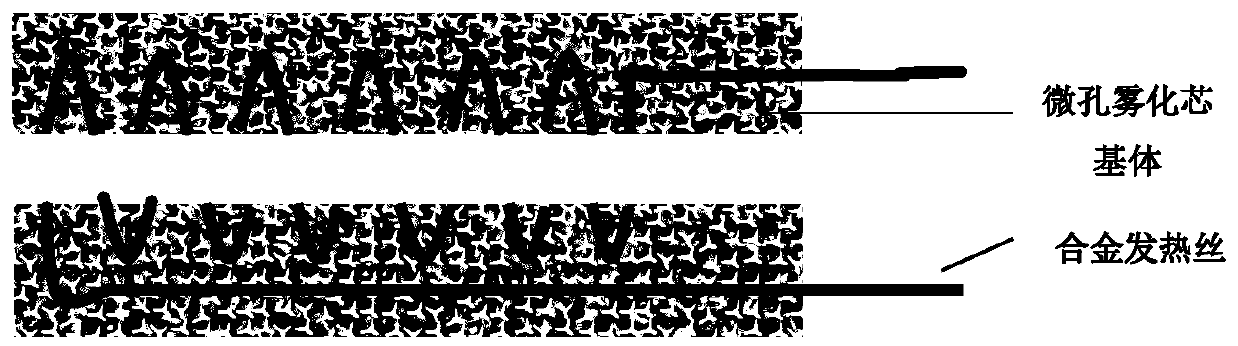

Preparation method of silicate-based microporous drug delivery atomizing core and heating component thereof

A technology for heating components and atomizing cores, applied in ceramic products, manufacturing tools, other household appliances, etc., can solve the problems of brittleness, easy oxidation, grain growth, etc., to achieve high strength, accurate size requirements, good structure The effect of strength and porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0038] A novel silicate-based microporous drug delivery atomizing core and its heating element were prepared. Prepare as follows:

[0039] (1) Mix 10 μm silicate clinker powder and pore-forming agent in a planetary ball mill, the ball-to-material ratio is 5:1, the diameter of the corundum ball is 1-5mm, and the ball milling speed is 200r / min, The ball milling time is 20 minutes, and the mixture after ball milling is taken out for later use, which is recorded as material a. Then mix water and material a according to the ratio of 0.5:1 and use it as the raw material of the atomizing core matrix for later use, which is recorded as material b; the silicate clinker contains 20wt.% dicalcium silicate and 7wt.% aluminate Tricalcium, 10wt.% tetracalcium aluminoferrate and 63wt.% tricalcium silicate, the pore-forming agent is ammonium bicarbonate, accounting for 2wt.% of the total mass of a;

[0040] (2) After assembling the mold and the heating element, spray the release agent. In t...

Embodiment example 2

[0045] A novel silicate-based microporous drug delivery atomizing core and its heating element were prepared. Prepare as follows:

[0046](1) Mix 8 μm silicate clinker powder and pore-forming agent in a planetary ball mill, the ball-to-material ratio is 3:1, the diameter of the corundum ball is 1-5mm, and the ball milling speed is 150r / min, The ball milling time is 15 minutes, and the mixture after ball milling is taken out for later use, which is recorded as material a. Then mix water and material a according to the ratio of 0.6:1 and use it as the raw material of the atomizing core matrix for later use, which is recorded as material b; the silicate clinker contains 22wt.% dicalcium silicate and 8wt.% aluminate Tricalcium, 15wt.% tetracalcium aluminoferrite and 55wt.% tricalcium silicate, the pore-forming agent is sodium bicarbonate accounting for 1wt.% of the total mass of a;

[0047] (2) After assembling the mold and the heating element, spray the release agent. The heati...

Embodiment example 3

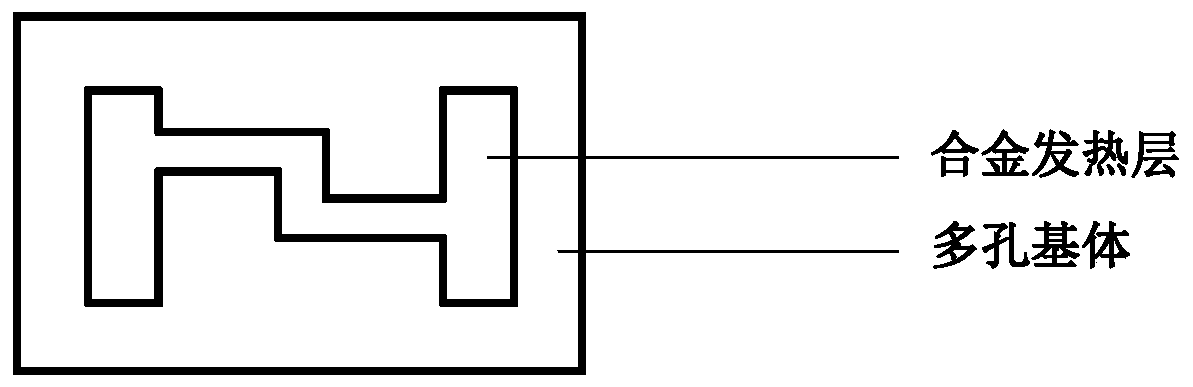

[0052] A new type of silicate-based microporous drug delivery atomization core and a heating element for atomization are prepared. Prepare as follows:

[0053] (1) Modeling: Use 3D drawing software to draw and model, and convert it in the slicing software dedicated to the 3D printer, and input the program into the 3D printer;

[0054] (2) Ingredients: Mix 2μm silicate clinker powder and pore-forming agent in a planetary ball mill, the ball-to-material ratio is 5:1, the diameter of the corundum ball is 1-5mm, and the ball milling speed is 250r / min, the ball milling time is 25min, take out the mixed material after ball milling, and record it as material a. Then mix water and material a according to the ratio of 0.4:1 and use it as the raw material of the atomizing core matrix for later use, which is recorded as material b; the silicate clinker contains 25wt.% dicalcium silicate and 5wt.% aluminate Tricalcium, 10wt.% tetracalcium aluminoferrite and 60wt.% tricalcium silicate, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com