Glass ceramic for realizing high dielectric constant and high breakdown performance by regulating glass network structure and preparation method thereof

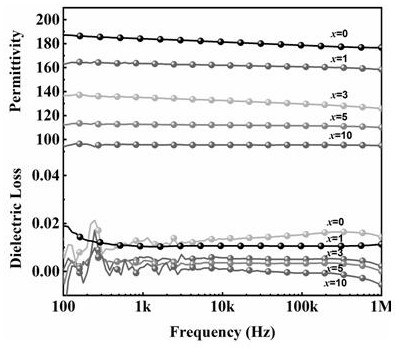

A technology of glass ceramics and dielectric constant, applied in the field of glass ceramics and its preparation, can solve the problems of difficult to achieve energy storage density, reduction of breakdown strength of glass matrix, etc., and achieve the effect of suppressing interface polarization and high energy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

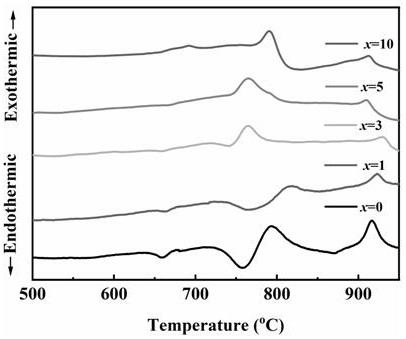

[0028] The crystallization treatment of the glass sample in this embodiment: heat preservation at the crystallization peak for 2 hours.

[0029] The preparation method of the glass-ceramic material of the present embodiment comprises the following steps:

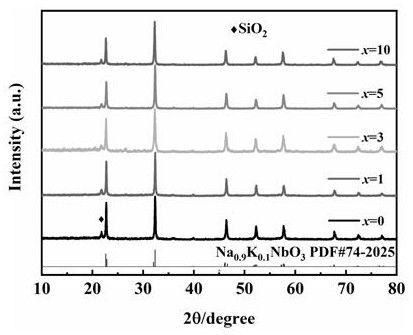

[0030] 1) The molar ratio of this embodiment is x : 1- x : 7: 8 ( x =0) La 2 o 3 、Na 2 CO 3 、K 2 CO 3 and Nb 2 o 5 ; The glass phase is SiO 2 ; The molar ratio of crystal phase and glass phase is 4:1.

[0031] 2) When heating the quartz crucible with the furnace from room temperature to 1100°C, start adding the mixture, then continue heating to 1500°C, and keep the temperature at 1500°C for 60 minutes to melt the mixture evenly to obtain a mixed molten material; put the mixed molten material on the copper plate Forming, then quickly put into the furnace and anneal at 500°C for 11 hours to obtain the annealed glass matrix;

[0032] 3) Keep warm at the crystallization peak temperature for 2h, and then cool down to...

Embodiment 2

[0035] In this example x=1;

Embodiment 3

[0037] In this example x =3;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com