Method for producing building material with low-temperature ceramic modified industry by-product gypsum

A technology of industrial by-product gypsum and low-temperature ceramics, which is applied in cement production, climate sustainability, and sustainable waste treatment. It can solve the problems of low strength, poor stability, and water resistance of gypsum products, and achieve high waste utilization efficiency. The effect of good product performance and mild curing conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

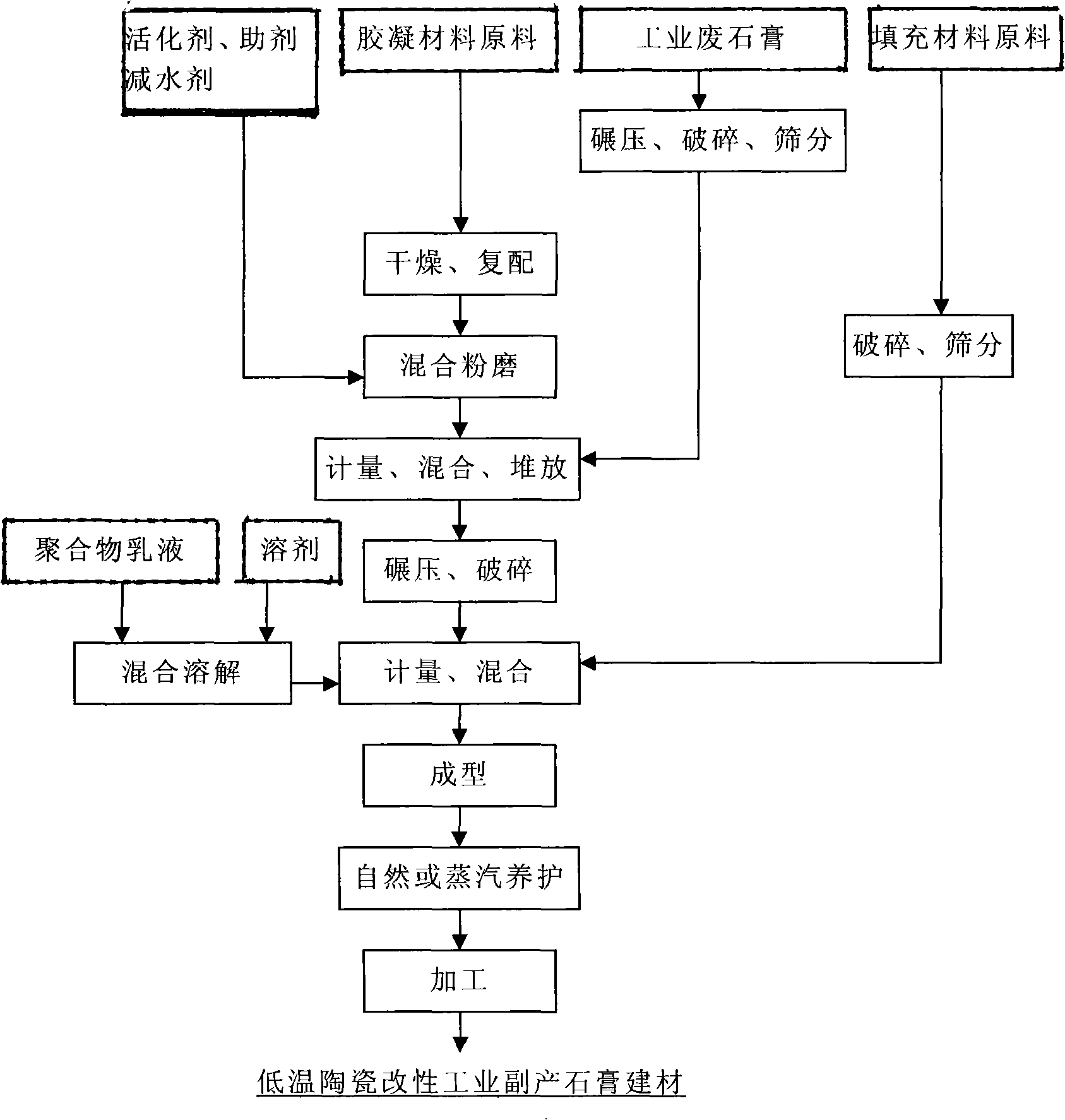

Image

Examples

Embodiment 1

[0027] 1) Formula composition (substance measurement units are parts by mass):

[0028] The raw materials of the cementitious material are 50 parts of yellow phosphorus slag, 20 parts of fly ash, and 30 parts of blast furnace slag; 25 parts; the activator is 10 parts of cement, 10 parts of lime, 60 parts of carbide slag; 2 parts of auxiliary solid water glass, 3 parts of aluminum sulfate, 2 parts of ferric chloride, 4 parts of aluminum potassium sulfate, and 1 part of ferrous sulfate; The water reducing agent is 0.3 parts of calcium lignosulfonate, 0.3 parts of sodium lignosulfonate, 0.3 part of naphthalene sulfonate, 0.1 part of sodium humate; 150 parts of phosphogypsum washing wastewater.

[0029] 2) Process: The cementitious material raw materials measured according to the formula, activator, auxiliary agent, and water reducing agent are blended and ground into a powder with a particle size of less than 0.08mm, accounting for 91%; phosphogypsum and desulfurized gypsum are f...

Embodiment 2

[0032] 1) Formula (substance measurement units are parts by mass)

[0033]The cementitious material is 20 parts of blast furnace slag, 20 parts of fly ash, 40 parts of calcined red mud, 20 parts of calcined alumina tailings; 150 parts of phosphogypsum in industrial by-product gypsum, 250 parts of desulfurization gypsum, 150 parts of titanium gypsum, 100 parts of citric acid gypsum, 100 parts of fluorine gypsum, 50 parts of wet-process manganese slag, 100 parts of lead-zinc slag; filler materials are 250 parts of tertiary fly ash, 250 parts of construction waste concrete; activator is 30 parts of lime, calcium carbide slag 85 parts; additives are 1 part of aluminum sulfate, 10 parts of ferric chloride, 10 parts of ferrous sulfate; water reducer is 5 parts of calcium lignosulfonate, 5 parts of sodium lignosulfonate; 500 parts of papermaking wastewater.

[0034] 2) Process: According to the formula, the cementitious material raw materials, activators, additives, and water reducer...

Embodiment 3

[0037] 1) Formula composition (substance measurement units are parts by mass):

[0038] The cementitious material is 30 parts of thermal manganese slag, 30 parts of phosphogypsum acid slag, 20 parts of calcined coal gangue, and 20 parts of steel slag; 50 parts of incineration slag, 100 parts of copper slag, 50 parts of waste concrete, 50 parts of waste brick, 200 parts of bagasse; the activator is 30 parts of cement, 90 parts of lime, 30 parts of carbide slag; 2 parts of auxiliary solid water glass, aluminum sulfate 8 parts, 10 parts of ferric chloride, 4 parts of aluminum potassium sulfate, 6 parts of ferrous sulfate; water reducing agent is 2.0 parts of calcium lignosulfonate, 2.0 parts of sodium lignosulfonate, 1.0 part of naphthalenesulfonate, humic acid 0.1 parts of sodium; 5.0 parts of polyvinyl acetate emulsion, 10.0 parts of silicon-acrylic emulsion, 0.5 parts of paraffin wax emulsion, 2.0 parts of polyvinyl alcohol, 2.5 parts of styrene-acrylic emulsion, 30 parts of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com