A bonded glass fiber reinforced plastic drive shaft with form-surface fit and its production process

A production process, fiberglass technology, applied in the field of drive shafts, can solve problems such as poor manufacturability, poor reliability, and low torsional strength, and achieve the effects of reducing difficulty, improving strength and reliability, and reducing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the drawings.

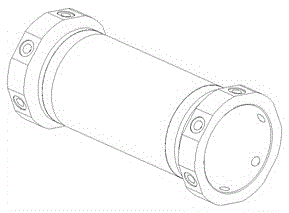

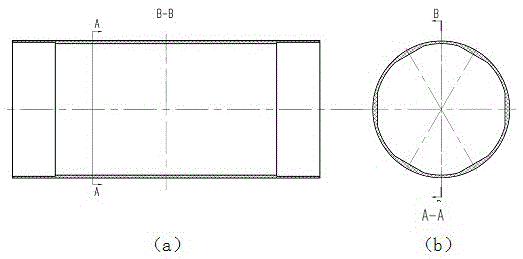

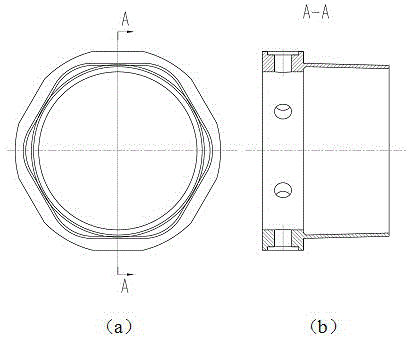

[0046] Such as Figure 3 to Figure 7 As shown, the present invention is mainly directed to, but not limited to, glass fiber reinforced plastic drive shafts applied to wind power couplings. The bonded glass fiber reinforced plastic drive shaft with profile matching includes a metal flange and a glass fiber reinforced plastic intermediate tube that are bonded together. The metal flange and the glass fiber reinforced plastic intermediate tube have bonding and mating surfaces, and the metal flange and The glass fiber reinforced plastic intermediate pipe has a hexagonal and arc transition mating surface, and the bonding and mating surface of the metal flange and the glass fiber reinforced plastic intermediate pipe is a hexagonal and arc transition bonding structure.

[0047] The end of the bonding structure adopts a linear matching form. The bonding and mating surfaces of the gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com