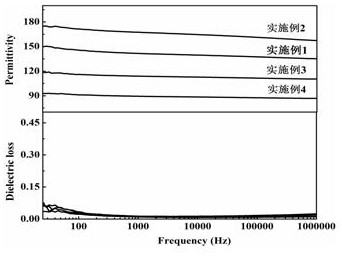

Contains nanbo 3 Phase na 2 o-k 2 o-nb 2 o 5 -sio 2 Low dielectric loss energy storage glass ceramics

A technology of glass ceramics, na2o-k2o-nb2o5-sio2, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problem of little research on potassium sodium niobate glass ceramic materials, low utilization of raw materials, and complex raw materials And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

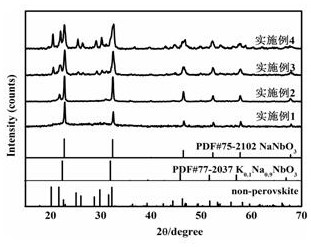

Embodiment 1

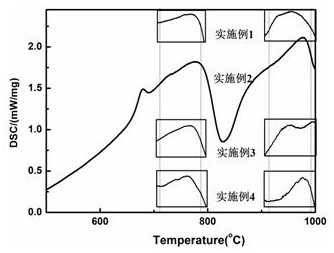

[0028]The crystallization treatment of the glass sample in this embodiment: heat insulation at 950 ° C for 4 h.

[0029]The preparation method of the glass ceramic material of the present embodiment includes the steps of:

[0030]1) The potassium sodium potassium potassium potassium acid glass ceramic material is 40% from the moles of mass.x: 40 (1-x: 40: 20 (x= 1), take NA2CO3K2CO3, NB2O5SiO2mixing.

[0031]2) When the stone crucible is heated from room temperature to 1100 ° C, the mixture is started, and then the mixture is added to 1500 ° C, and the holding 60 min is charged at 1500 ° C for 60 min to uniformly melt, to obtain a mixed melt; mixed melt in the copper plate Forming, rapidly discharged into the furnace at 500 ° C for 11 h, and the glass substrate after annealing is obtained;

[0032]3) Continue at 905 ° C for 1 h at 708 ° C for 4 hours and then cooled to room temperature, resulting in K2O-NA2O-NB2O5-Sio2-B2O3System glass ceramic material.

[0033]Potassium niobate sodium ceramics ob...

Embodiment 2

[0035]The formulation of the glass sample in this embodiment is 40x: 40 (1-x: 40: 20 (x= 0.9) and fused at 1500 ° C and incubated for 60 min, and other conditions as in Example 1.

Embodiment 3

[0037]The formulation of the glass sample in this embodiment is 40x: 40 (1-x: 40: 20 (x= 0.8), other conditions as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com