Strontium barium niobate glass ceramic material with high dielectric constant and high breakdown field strength and preparation method thereof

A high dielectric constant, barium strontium niobate technology, applied in the field of glass ceramic materials and its preparation, can solve the problems of reducing crystallization tendency, limiting the application of energy storage materials, increasing the breakdown field strength of materials, etc., and achieving high breakdown Field strength, multiple molding methods, and high breakdown field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

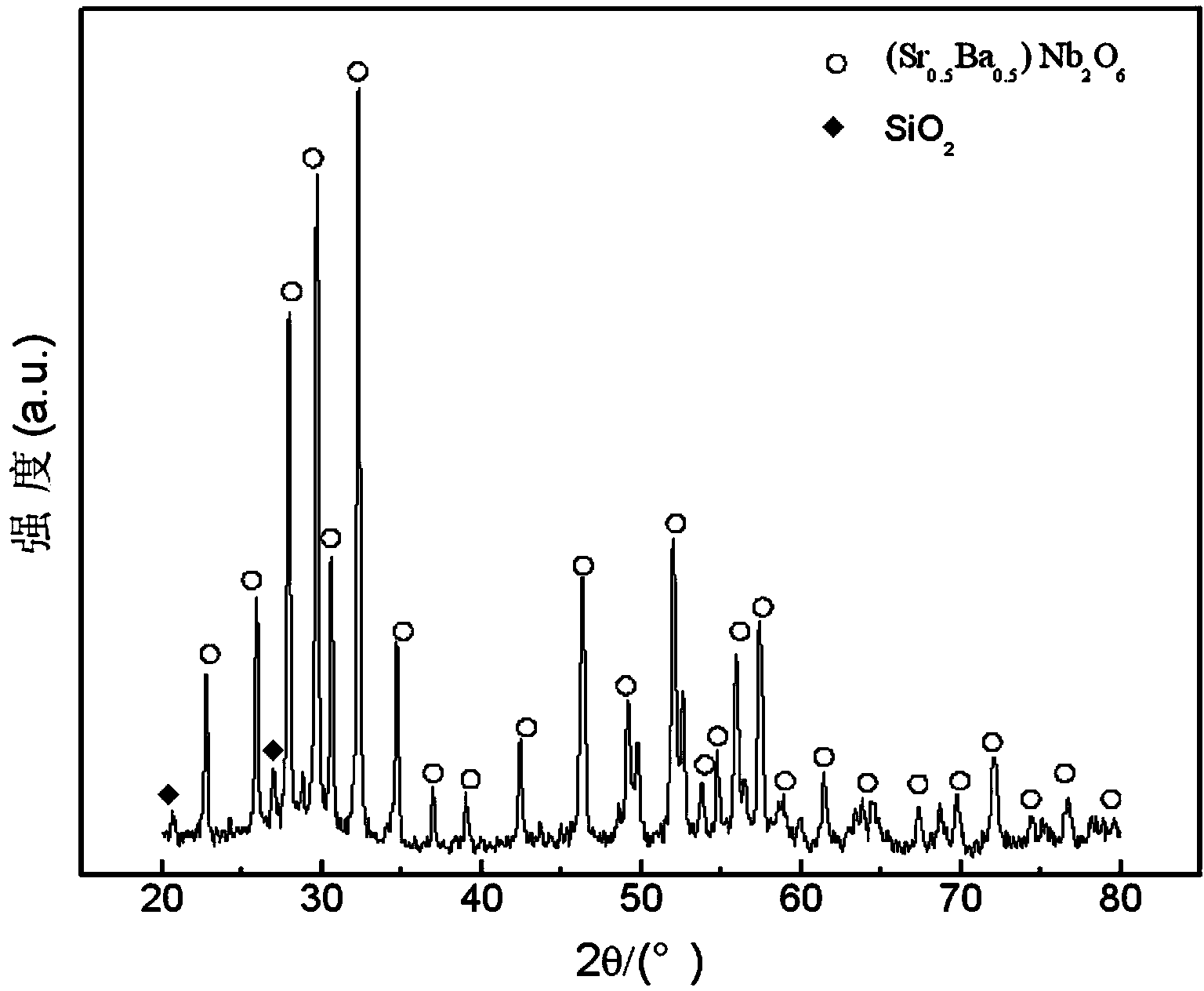

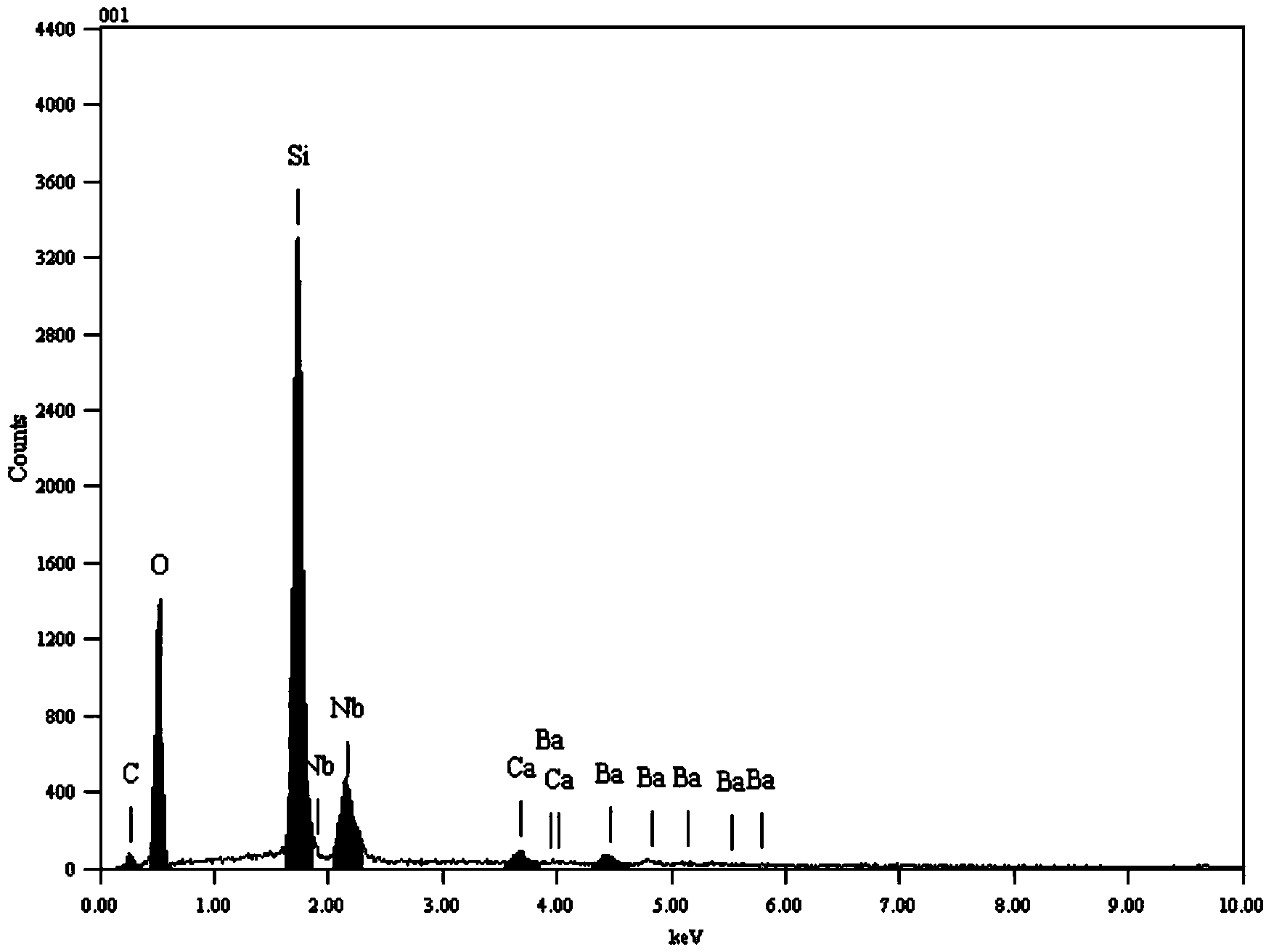

[0024] In this embodiment, the barium strontium niobate glass-ceramic material comprises SrO, BaO, Nb with a molar ratio of 12:12:24:10:10:15:3 2 o 5 , CaO, SiO 2 , B 2 o 3 and BaF 2 .

[0025] The barium strontium niobate glass-ceramic material in this embodiment is made of SrCO with a molar ratio of 12:12:24:10:10:30:3 3 , BaCO 3 , Nb 2 o 5 , CaCO 3 , SiO 2 , H 3 BO 3 and BaF 2 It is prepared by melting, molding, annealing and crystallization.

[0026] The preparation method of barium strontium niobate glass-ceramic material of the present embodiment comprises the following steps:

[0027] 1) SrCO 3 、BaCO 3 , Nb 2 o 5 , CaCO 3 , SiO 2 、H 3 BO 3 and BaF 2 Mix evenly according to 12:12:24:10:10:30:3 to obtain a mixture;

[0028] 2) When the quartz crucible is heated with the furnace from room temperature to 1100°C, start to add the mixture, then continue to heat to 1350°C, and keep it at 1350°C for 30 minutes to melt the mixture evenly to obtain a mixed...

Embodiment 2

[0032] The barium strontium niobate glass-ceramic material of this embodiment comprises SrO, BaO, Nb with a molar ratio of 12:12:24:12:12:18:3 2 o 5 , CaO, SiO 2 , B 2 o 3 and BaF 2 .

[0033]The barium strontium niobate glass-ceramic material in this embodiment is made of SrCO with a molar ratio of 12:12:24:12:12:36:3 3 , BaCO 3 , Nb 2 o 5 , CaCO 3 , SiO 2 , H 3 BO 3 and BaF 2 It is prepared by melting, molding, annealing and crystallization.

[0034] The preparation method of barium strontium niobate glass-ceramic material of the present embodiment comprises the following steps:

[0035] 1) SrCO 3 , BaCO 3 , Nb 2 o 5 , CaCO 3 , SiO 2 , H 3 BO 3 and BaF 2 Mix evenly according to 12:12:24:12:12:36:3 to obtain a mixture;

[0036] 2) When the quartz crucible is heated from room temperature to 1100°C with the furnace, start to add the mixture, then continue to heat to 1350°C, and keep it at 1350°C for 30 minutes to melt the mixture evenly to obtain a mixed...

Embodiment 3

[0040] The barium strontium niobate glass-ceramic material of this embodiment comprises SrO, BaO, Nb with a molar ratio of 12:12:24:14:14:21:3 2 o 5 , CaO, SiO 2 , B 2 o 3 and BaF 2 .

[0041] The strontium barium niobate glass-ceramic material in this embodiment is made of SrCO with a molar ratio of 12:12:24:14:14:42:3 3 , BaCO 3 , Nb 2 o 5 , CaCO 3 , SiO 2 , H 3 BO 3 and BaF 2 It is prepared by melting, molding, annealing and crystallization.

[0042] The preparation method of barium strontium niobate glass-ceramic material of the present embodiment comprises the following steps:

[0043] 1) SrCO 3 , BaCO 3 , Nb 2 o 5 , CaCO 3 , SiO 2 , H 3 BO 3 and BaF 2 Mix evenly according to the molar ratio of 12:12:24:14:14:42:3 to obtain the mixture;

[0044] 2) When the quartz crucible is heated from room temperature to 1100°C with the furnace, start to add the mixture, then continue to heat to 1350°C, and keep it at 1350°C for 30 minutes to melt the mixture ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com