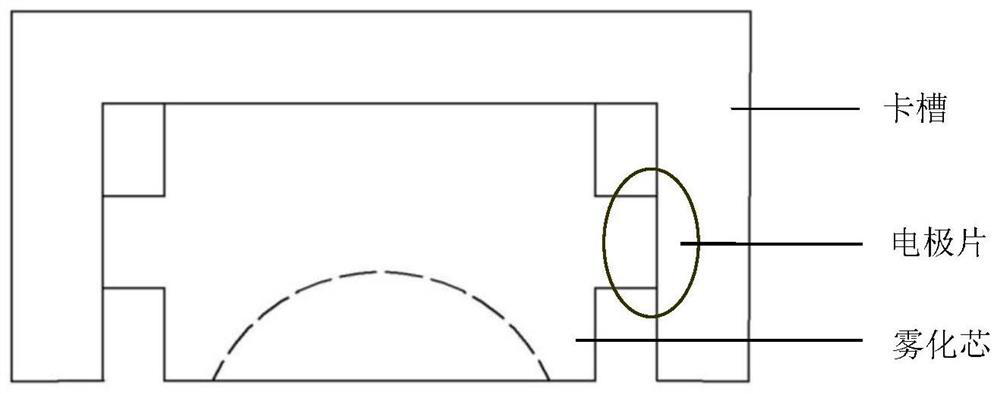

Preparation method of an easy-to-assemble self-heating porous titanium-based drug delivery atomizer core

An atomizing core and porous titanium technology, which is applied in the field of preparation of self-heating porous titanium-based drug delivery atomizing cores, can solve problems such as low resistivity of titanium alloys, and achieve controllable porosity, free and flexible design, and various molding methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] To prepare an easy-to-assemble self-heating porous titanium-based drug delivery atomization core, the preparation is as follows:

[0038] (1) Titanium powder, 30wt.% iron powder, and 20wt.% potassium chloride were weighed according to the proportion, and then mixed in a mixer for 2 hours, and the mixed powder was obtained after uniform mixing.

[0039] (2) Mix the mixed powder with 5vol.% paraffin wax, perform ball milling for 0.5h, then granulate, and pass through a 100-mesh sieve to obtain the material for pressing samples.

[0040] (3) Apply lubricating oil or zinc stearate on the surface of the mold, put the material for pressing the sample into the pressing mold of the target shape, press and form under the pressure of 50MPa, hold the pressure for 10s, and get the green body of the desired shape after taking it out .

[0041] (4) Put the green body in a sintering furnace, carry out argon sintering, keep it at 400°C for 4 hours, then keep it at 1200°C for 90 minute...

Embodiment 2

[0043] To prepare an easy-to-assemble self-heating porous titanium-based drug delivery atomization core, the preparation is as follows:

[0044] (1) Weigh titanium alloy powder and aluminum powder according to a certain weight ratio of 4:1, and add 20wt.% sodium chloride, and then put them into a mixer for mixing. The mixing time is 6 hours, and the mixed mixture is obtained after uniform mixing. powder;

[0045] (2) Mix the mixed powder with the plastic-based binder for injection in a certain proportion, wherein the mixed powder accounts for 60vol.%, and the binder accounts for 40vol.%. The mixture is mixed for 0.5h by ball milling, and then mixed in the internal mixer Carry out kneading, the kneading temperature is 180°C, and the duration is 60min;

[0046](3) Put the mixed material into the crushing and granulating machine for crushing and granulating, and then obtain the feeding material for injection;

[0047] (4) First install the mold of the target shape in place, inj...

Embodiment 3

[0051] To prepare an easy-to-assemble self-heating porous titanium-based drug delivery atomization core, the preparation is as follows:

[0052] (1) Weigh titanium powder, copper powder, and aluminum powder according to a certain ratio, wherein titanium powder: copper powder: aluminum powder = 5:1:2, and add 10wt.% paraffin, and use a mixer for mixing , the mixing time is 3 hours, and the mixed powder is obtained after uniform mixing;

[0053] (2) Mix the mixed powder and toluene solvent in a certain proportion, wherein the mixed powder accounts for 70vol.%, the binder accounts for 30wt%, then add 0.5wt.% oleic acid, 0.2wt.% PVB solution, and mix for 1h , to obtain a mixed slurry;

[0054] (3) Pour the mixed slurry into the silica gel bag of the target shape, dry at 40°C for 4 hours, and wait for it to solidify and form;

[0055] (4) taking out the dried green body from the sheath to obtain the atomizing core green body;

[0056] (5) Place the atomizing core blank in a sint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com