Phosphorus-based flame-retardant glass fiber reinforced plastic floor paint and construction method thereof

A phosphorus-based flame retardant and floor paint technology, used in the field of floor paint, can solve the problems of scratch resistance, high temperature flame retardant and weather resistance, inability to resist underground moisture, long curing time, etc., and achieve various molding methods. , low cost, simple and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

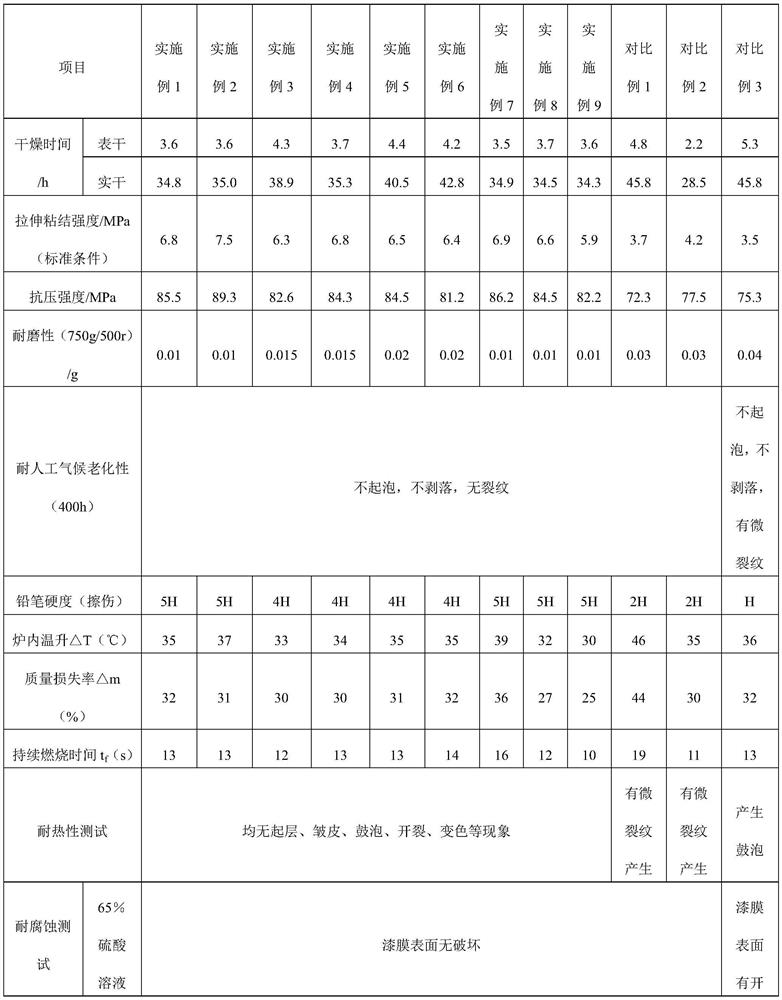

Examples

Embodiment 1

[0033] A phosphorus flame retardant FRP floor paint comprises the following components in parts by weight: 70 parts of phosphorus flame retardant unsaturated polyester resin, 30 parts of chopped glass fiber, 1 part of cobalt isooctanoate and 2 parts of methyl ethyl ketone peroxide.

[0034] The phosphorus-based flame-retardant unsaturated polyester resin of this embodiment is prepared by reacting the following raw material components in weight percent: 30% ethylene glycol, 10% propylene glycol, 22% CEPA, 13% maleic anhydride and 25% styrene.

[0035] The construction method of the floor paint of the present embodiment may further comprise the steps:

[0036] (1) After stirring the phosphorus-based flame-retardant unsaturated polyester resin and cobalt isooctanoate evenly, add it to the container of the automatic injection machine;

[0037] (2) Prepare the chopped glass fiber;

[0038] (3) Through the automatic injection machine, while adding the curing agent, the mixed materi...

Embodiment 2

[0041] A phosphorus-based flame-retardant FRP floor paint, comprising the following components in parts by weight: 70 parts of phosphorus-based flame-retardant unsaturated polyester resin, 30 parts of aminosilane coupling agent surface modified chopped glass fiber, 1 cobalt isooctanoate Parts and 2 parts of methyl ethyl ketone peroxide.

[0042] The phosphorus-based flame-retardant unsaturated polyester resin of this embodiment is prepared by reacting the following raw material components in weight percent: 30% ethylene glycol, 10% propylene glycol, 22% CEPA, 13% maleic anhydride and 25% styrene.

[0043] The construction method of the floor paint of the present embodiment may further comprise the steps:

[0044] (1) After stirring the phosphorus-based flame-retardant unsaturated polyester resin and cobalt isooctanoate evenly, add it to the container of the automatic injection machine;

[0045] (2) Prepare the chopped glass fiber;

[0046] (3) Through the automatic injection...

Embodiment 3

[0049] A phosphorus flame retardant FRP floor paint comprises the following components in parts by weight: 60 parts of phosphorus flame retardant unsaturated polyester resin, 40 parts of chopped glass fiber, 0.5 part of cobalt isooctanoate and 1 part of methyl ethyl ketone peroxide.

[0050] The phosphorus-based flame-retardant unsaturated polyester resin of this embodiment is prepared by reacting the following raw material components in weight percent: 30% ethylene glycol, 10% propylene glycol, 22% CEPA, 13% maleic anhydride and 25% styrene.

[0051]The construction method of the floor paint of the present embodiment may further comprise the steps:

[0052] (1) After stirring the phosphorus-based flame-retardant unsaturated polyester resin and cobalt isooctanoate evenly, add it to the container of the automatic injection machine;

[0053] (2) Prepare the chopped glass fiber;

[0054] (3) Through the automatic injection machine, while adding the curing agent, the mixed materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com