High-temperature and high-pressure rigidity seal hydrophobic ball valve

A high-temperature, high-pressure, hard-sealed technology, applied to shaft seals, valve details, valve devices, etc., can solve problems such as serious erosion of sealing surfaces, short service life of valves, and impact on unit efficiency, so as to achieve good overall sealing performance and ensure stability , Improving the service life and the effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

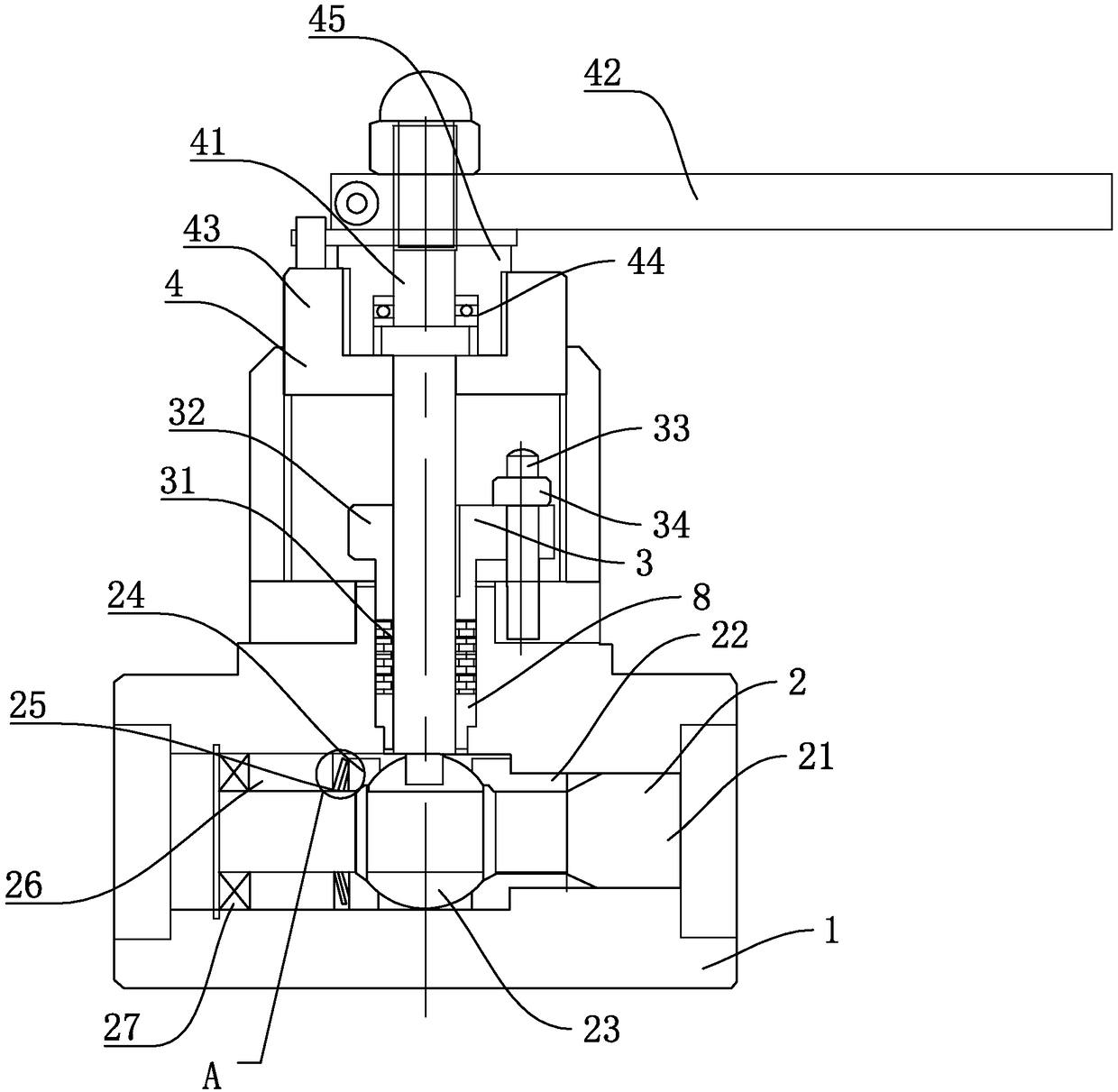

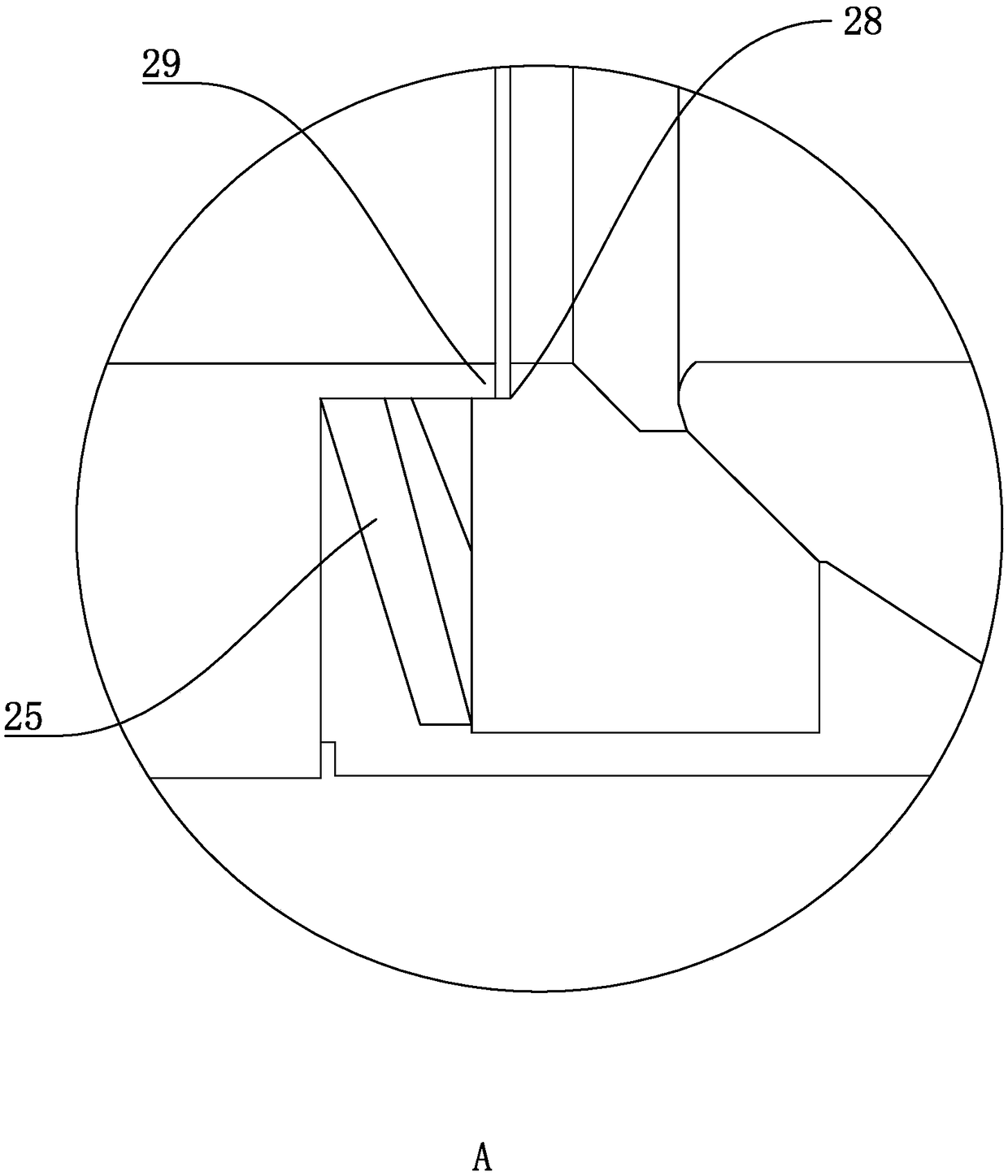

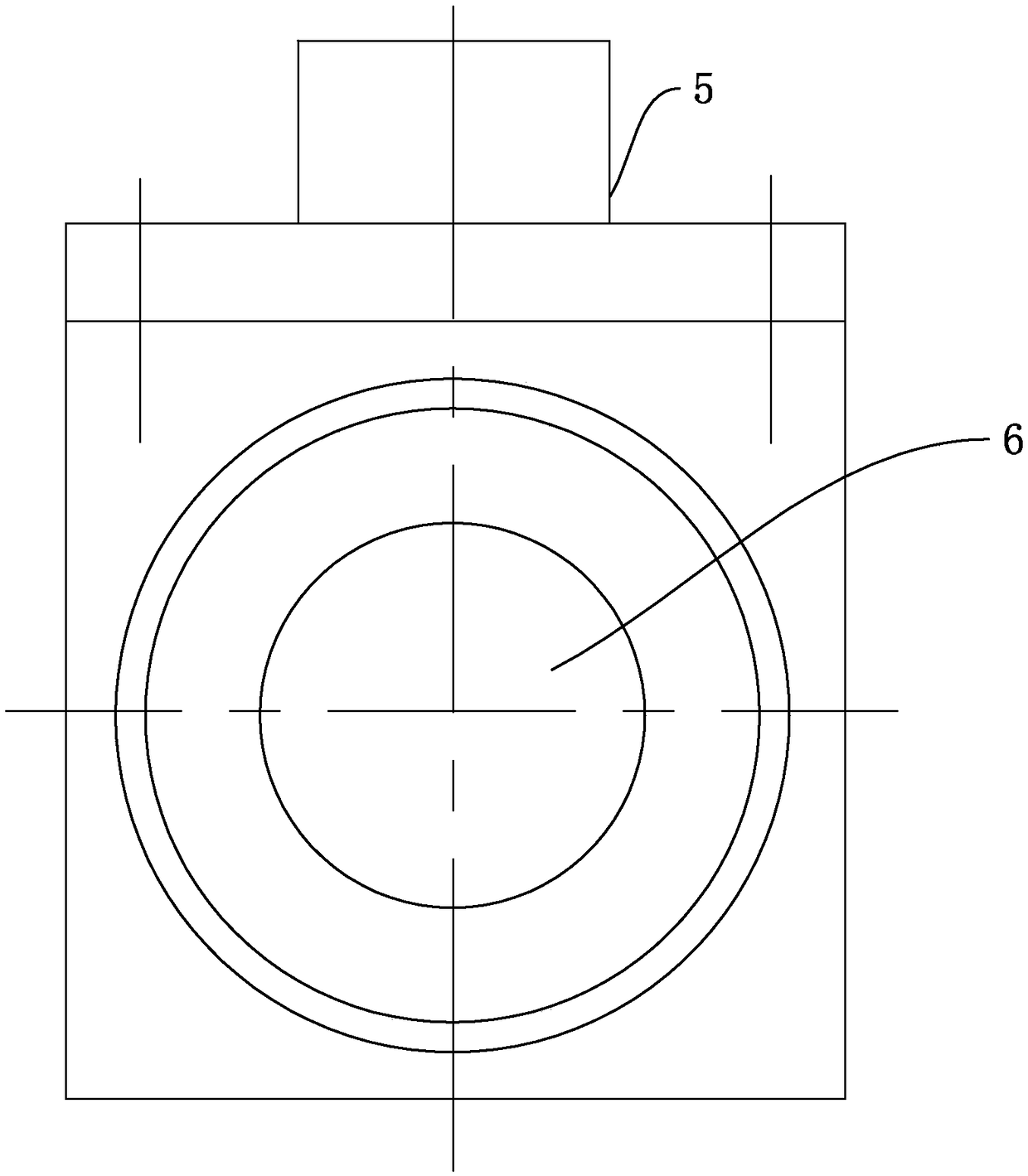

[0027] Example 1: A high temperature and high pressure hard-sealed hydrophobic ball valve, as shown in Figure 1, figure 2 and image 3 As shown, the valve body 1 is included, and the valve body 1 is provided with a sealing device 2. The sealing device 2 includes a channel 21 located in the valve body 1, and a fixed valve seat 22 is fixedly welded on the right side of the valve body 1. There is also a valve seat 22 in the valve body 1 There is a valve ball 23 that forms the main sealing valve with the fixed valve seat 22, and a movable valve seat 24 is provided on the other side of the channel 21, and a compression spring 25 that fits the valve ball 23 is also provided on the movable valve seat 24, and The compression spring 25 is also provided with an adjusting bonnet 26 at one end away from the valve ball 23, and a spring retaining ring 27 is also provided at the side of the adjusting bonnet 26 away from the compression spring 25, and an inner hole step is also provided at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com