Sliding bearing

A technology of sliding bearings and bearing alloys, applied in bearings, bearing components, shafts and bearings, etc., can solve the problems of poor sintering resistance, insufficient adaptability, and uneven coating of lubricating oil, etc. The effect of improving sinterability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

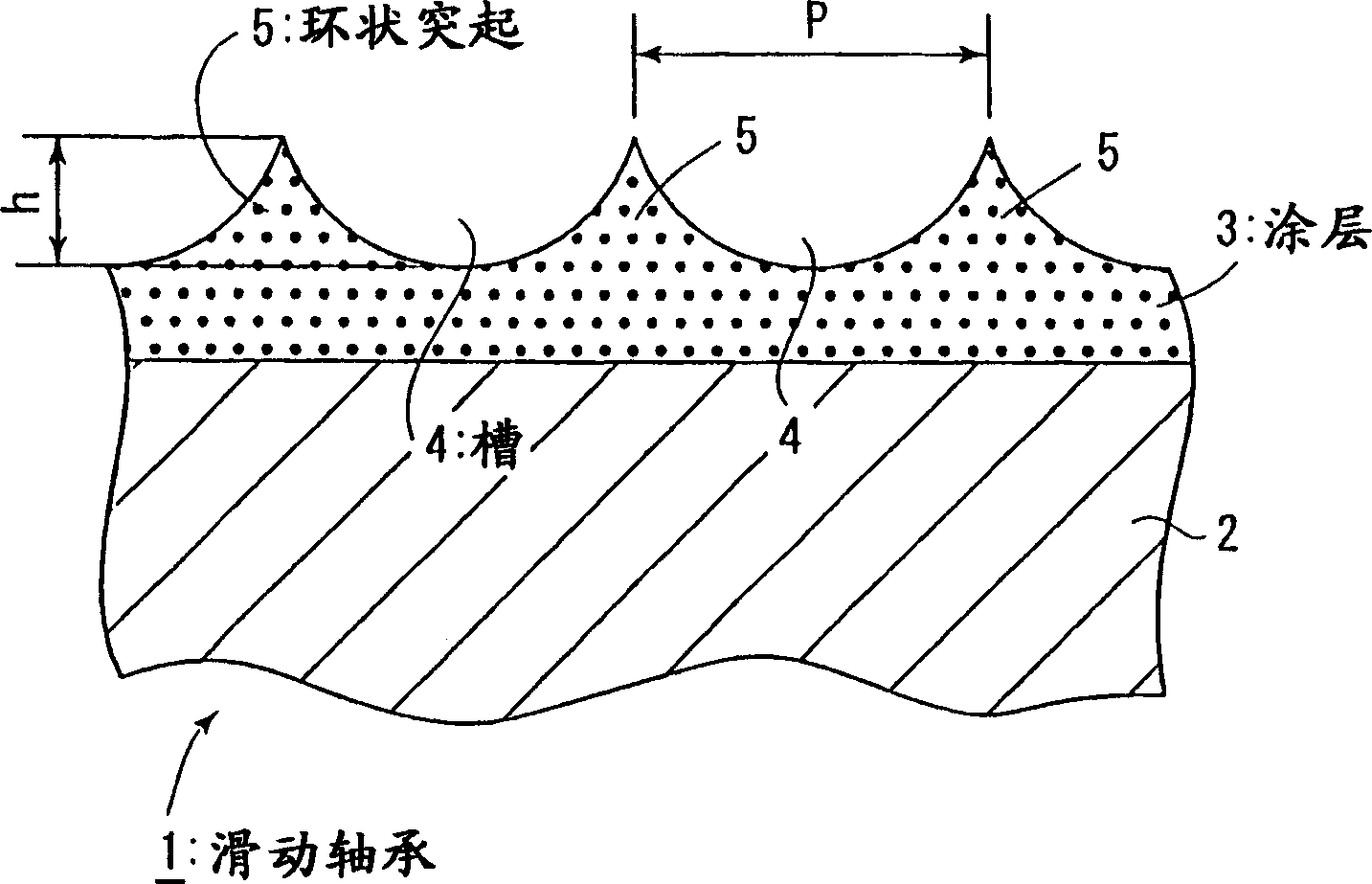

[0015] The invention is illustrated for the following illustrated examples, figure 1 An enlarged view showing a cross section along the axial direction of the cylindrical sliding bearing 1 . This sliding bearing 1 is composed of a bearing pad lining layer not shown in the figure, a bearing alloy layer 2 formed on the surface of the sliding bearing 1 on the center side opposite to the bearing pad lining layer, and further formed on the surface of the bearing alloy layer 2 . Coating 3 constitutes.

[0016] The above-mentioned bearing alloy layer 2 is composed of an alloy with copper and aluminum as the main raw materials, and its inner peripheral surface is parallel to the axial direction of the sliding bearing 1, and is processed into a flat surface with very fine roughness, while the coating 3 is formed as a solid lubricant MoS 2 Composed of PAI resin as a binder resin, the coating layer 3 is sprayed on the surface of the flattened bearing alloy layer 2 by air jet spraying, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com