Large-sized high-pressure movable bend structure

A kind of movable elbow, large-scale technology, applied in drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of limited structural forming method of elbow, limited volume requirements, large structural volume, etc., and achieve various forming methods. , reliable connection, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

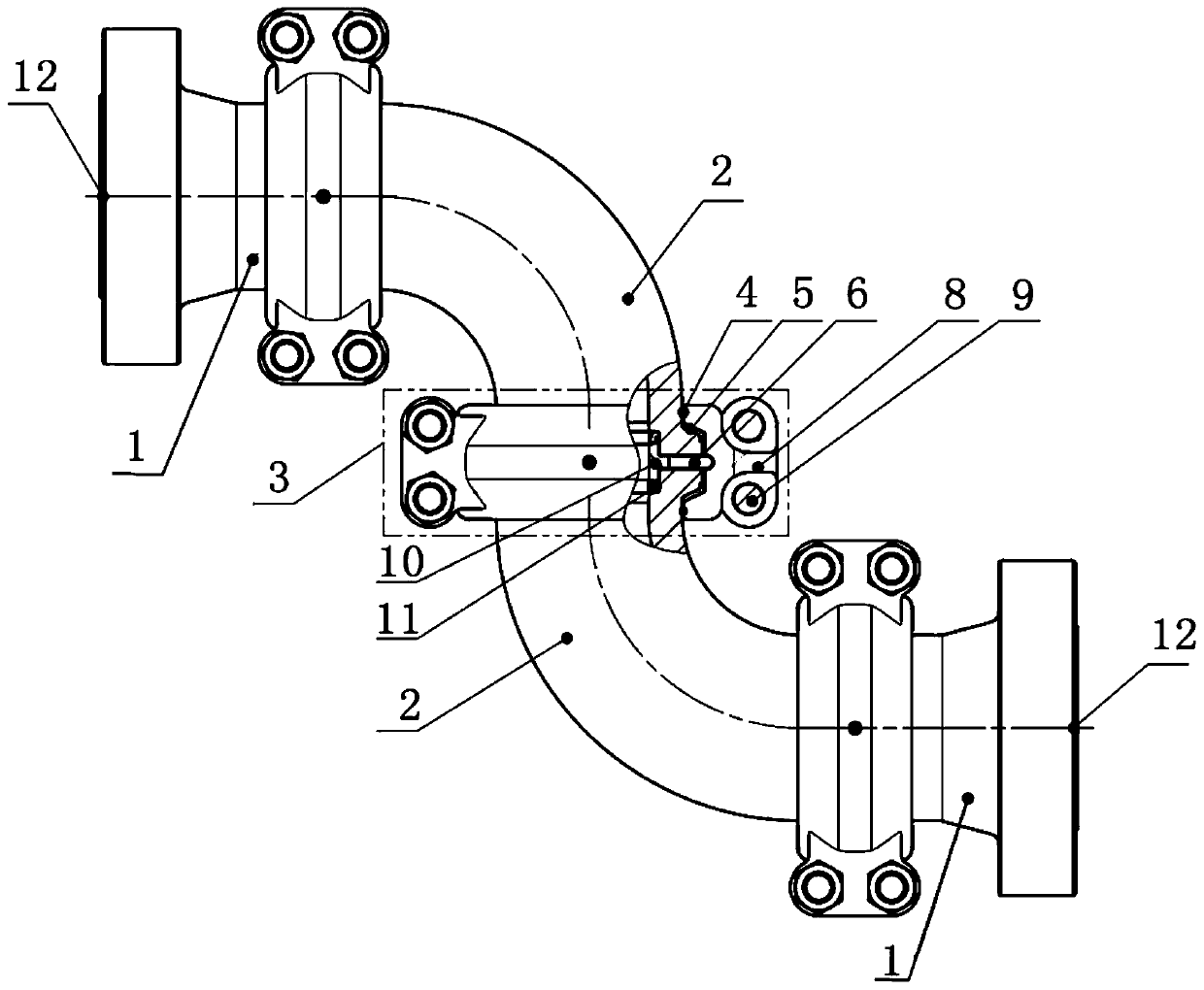

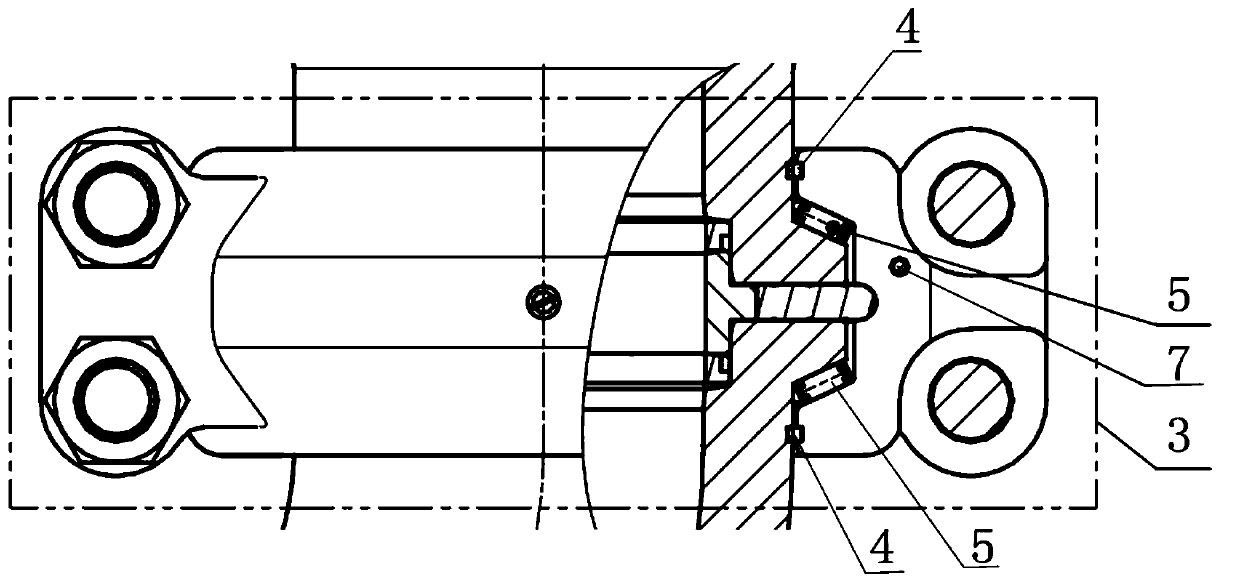

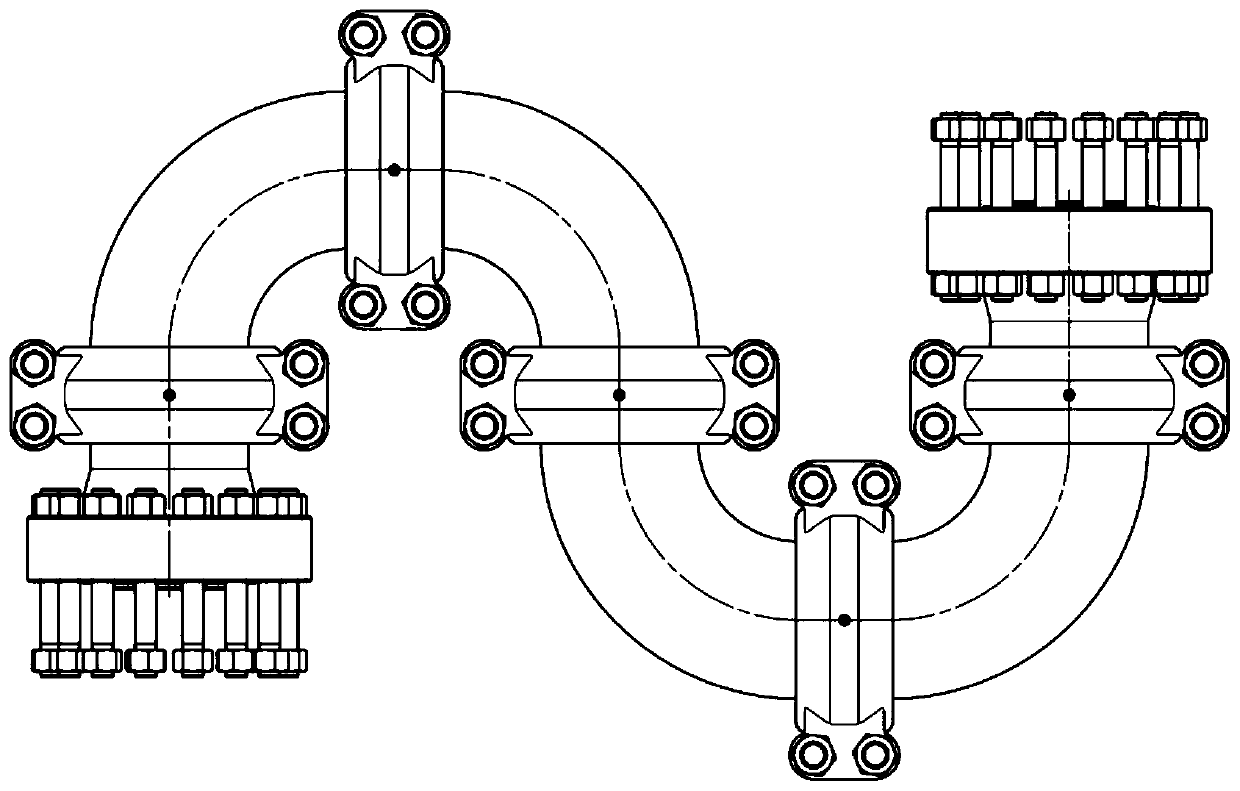

[0027] Such as Figures 1 to 4 As shown, a large-scale high-pressure swivel elbow structure includes a connecting head 1, an elbow 2 and a hinge assembly 3. Between the connecting head 1 and the elbow 2, and between the elbow 2 and the elbow 2, the The joint assembly 3 is connected, and the joint head 1 is used for connecting with upstream and downstream equipment; , the sealing connection between the elbow 2 and the elbow 2, the clamp 8 is used for the connection and fixation between the connecting head 1 and the elbow 2, and between the elbow 2 and the elbow 2. The connection between the hoop 8 and the connector 1 or between the hoop 8 and the elbow 2 is connected by a rotating part 5, and the rotating part 5 can be deformed and designed as various forms of rolling bearings or sliding bearings, so as to reduce the A form of frictional resistance. The sealed connection between two adjacent connecting heads 1 and elbow 2, and between the elbow 2 and elbow 2 is realized throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com