In-slot self-cooling high-speed permanent magnetic motor system for compressor

A permanent magnet motor and self-cooling technology, applied in the field of electric motors, can solve the problems of insufficient permanent magnet strength, easy damage, loss density of high-power and high-density motors, and difficulty in dissipating heat, and achieves effective and safer protection. The effect of the rotor generating heat, increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

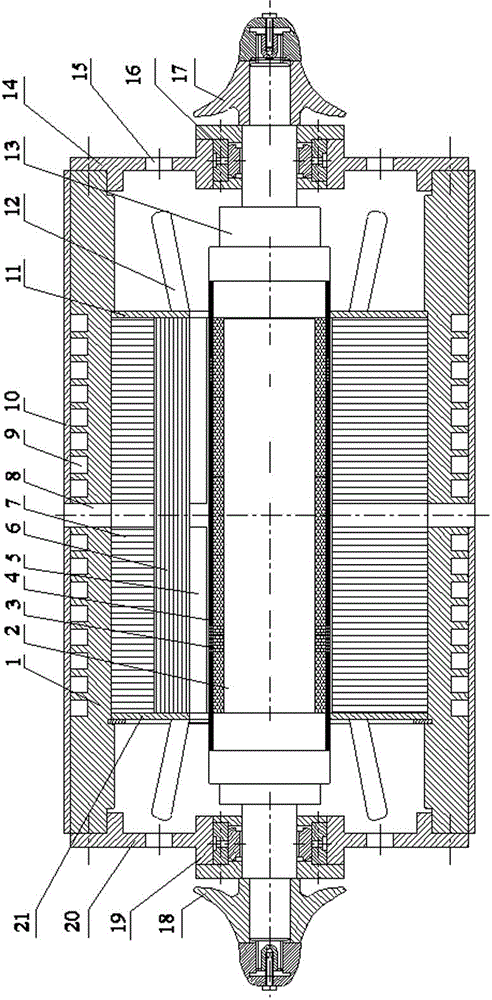

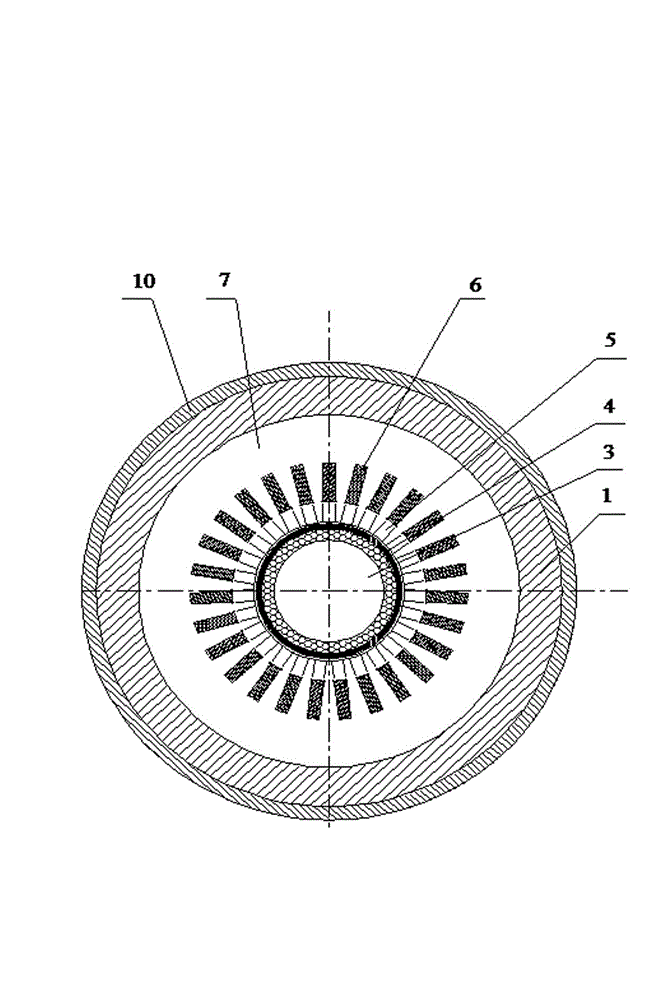

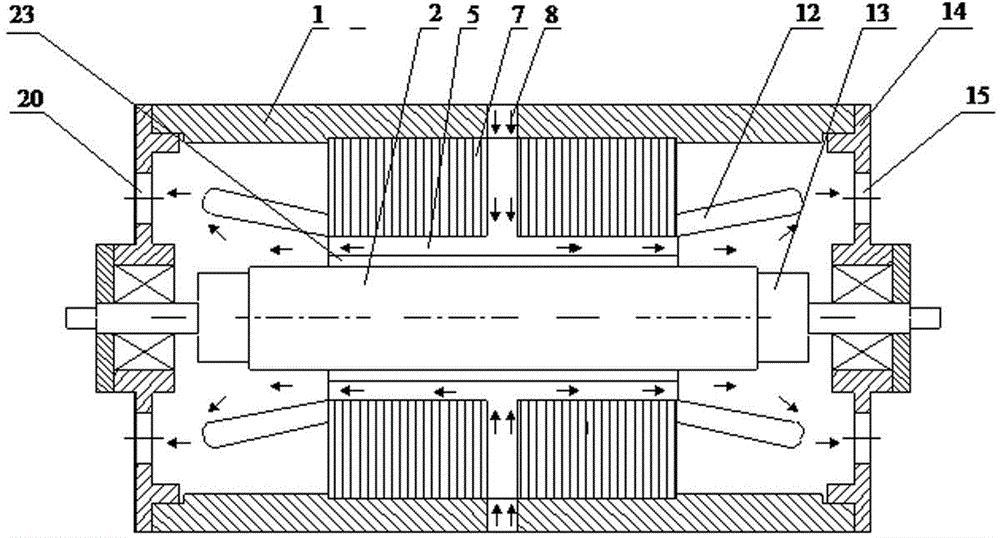

[0028] The invention will be further described below in conjunction with the accompanying drawings.

[0029] The present invention provides a self-cooling high-speed permanent magnet motor system in a tank for a compressor, which includes a casing 1 and a stator and a rotor arranged in the casing 1, and the two ends of the casing 1 are respectively provided with a left end cover 20 and a right end cover 14 , a cooling water jacket is arranged outside the casing 1, and the inside of the cooling water jacket is a circumferential spiral water channel 9; the stator includes a stator core 7, a stator winding 6 and a winding pressure plate, and the stator winding is arranged on the stator core 7, and the stator A radial air duct 8 is arranged in the middle of the iron core 7, and the radial air duct 8 communicates with the axial inner air duct 5 arranged on the periphery of the rotor; The air outlet 15 that wind draws.

[0030] The rotor is composed of a rotor core 2, a per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com