Extrusion molding method for ceramic pin blank tube with core and extrusion head thereof

An extrusion molding and extrusion head technology, applied in ceramic molding machines, ceramic extrusion dies, coupling of optical waveguides, etc., can solve the high requirements of grinding machine precision grinding wheel durability, easy bending deformation, complex grinding process and other problems, to achieve the effect of reducing the difficulty of mechanical processing, easy disassembly and replacement, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

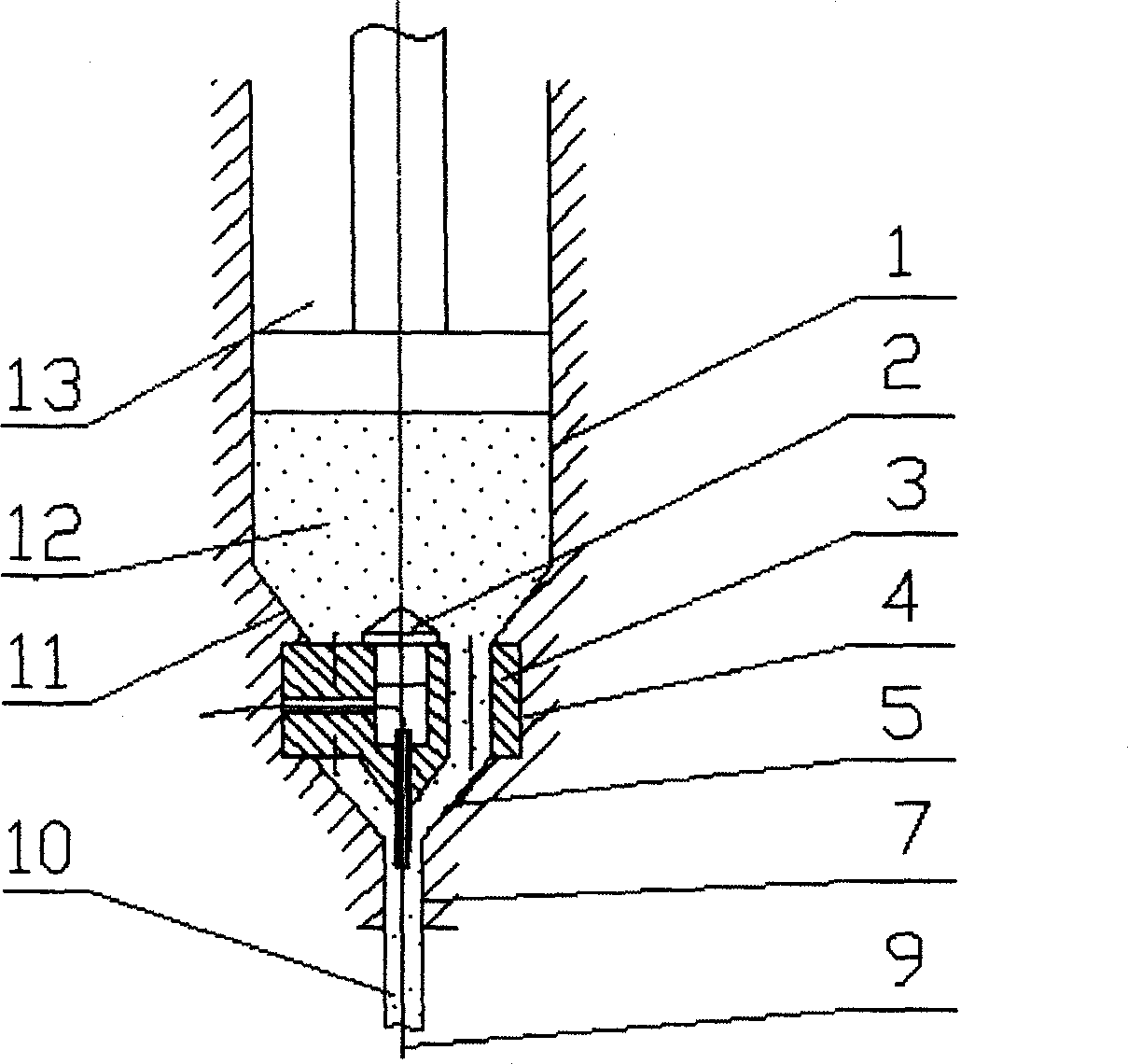

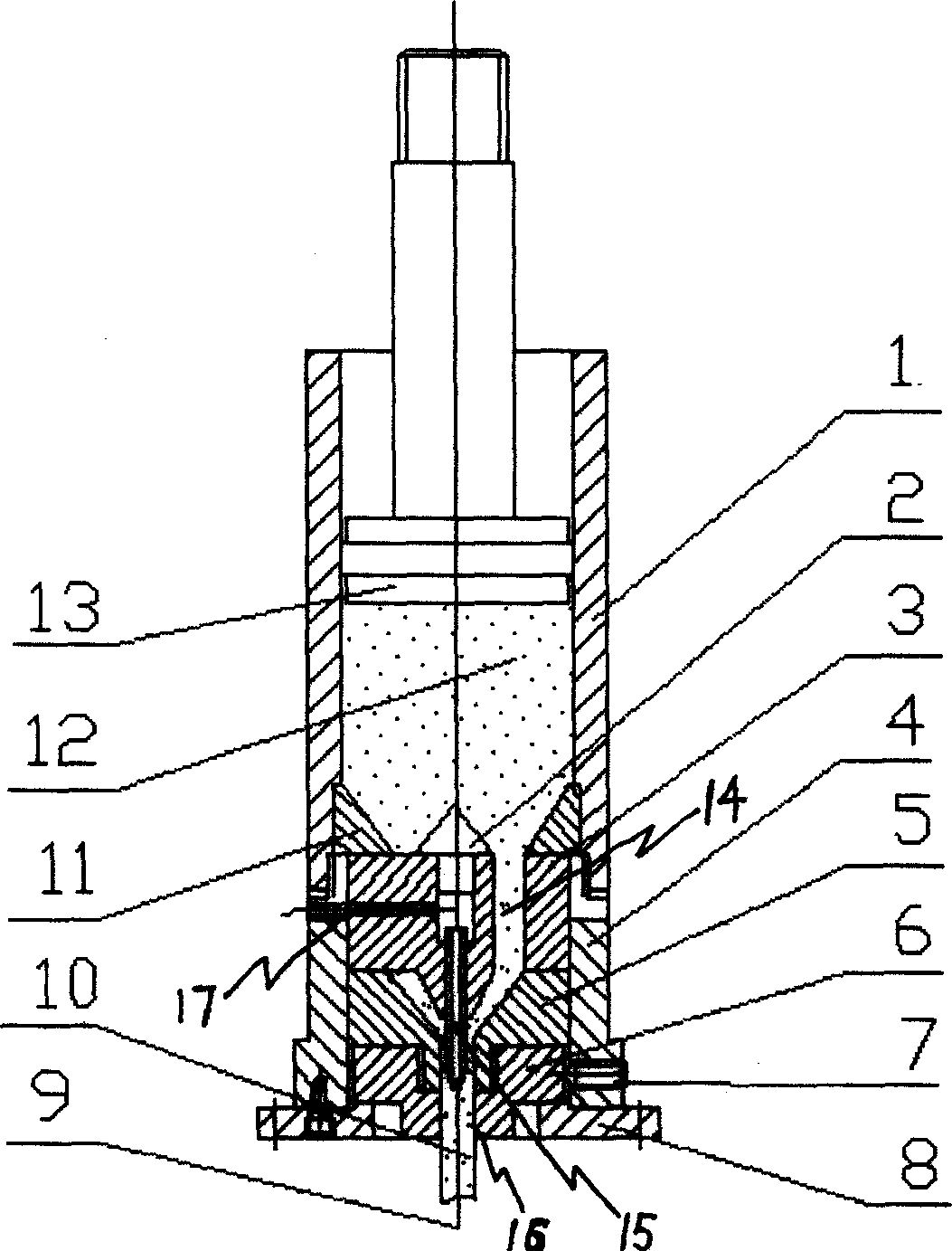

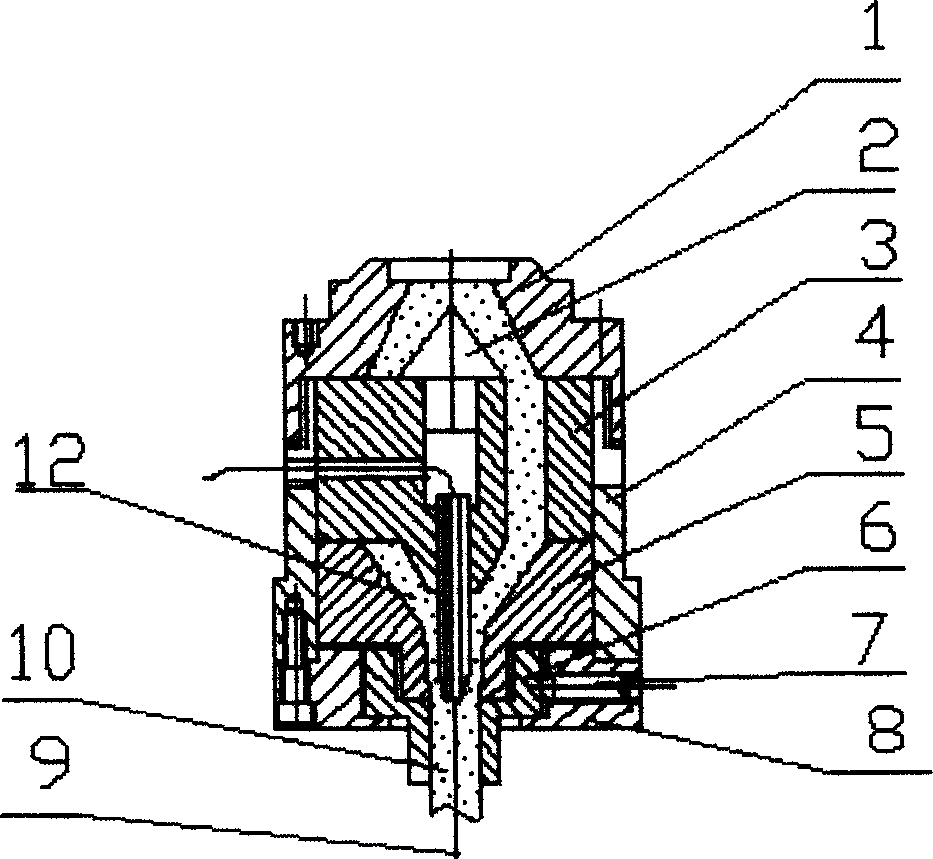

[0019] refer to Figure 1 to Figure 6 , what the present invention describes is a core-containing extrusion molding method for a ceramic pin blank tube, the steps of which are: extruding the extruded sludge 12 in an extruder containing an extrusion head to form a core-containing wire The pin material 10 of 9, after the material 10 is straightened and dried, the pin material 10 is machined to make pin blanks 18.1, 18.2, 18.3, and then the pin blanks are obtained by degreasing and high-temperature sintering Tube.

[0020] A further technical solution may be: automatically and continuously wrap the core wire 9 of a certain diameter in the center of the ceramic mud 12 during the extrusion process of the ceramic mud 12 to become the pin material 10, and after the material 10 is dried, extract the core Silk 9 obtains the central aperture.

[0021] A further technical solution may also be: use a machine tool to mechanically process the material 10, cut off, chamfer, and process the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com