Propelling-stable cannonball support for air cannon and design method of cannonball support

A technology of air cannons and bullet holders, which is applied in the direction of launching devices and sustainable transportation, can solve the problems of large leakage in the gap of ordinary bullet holders, affecting the propulsion efficiency of the bullet holder, and unstable propulsion, so as to reduce the design and mechanical processing Difficulty, reduce loss, and ensure the effect of stable launch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment is the embodiment of the flick support structure.

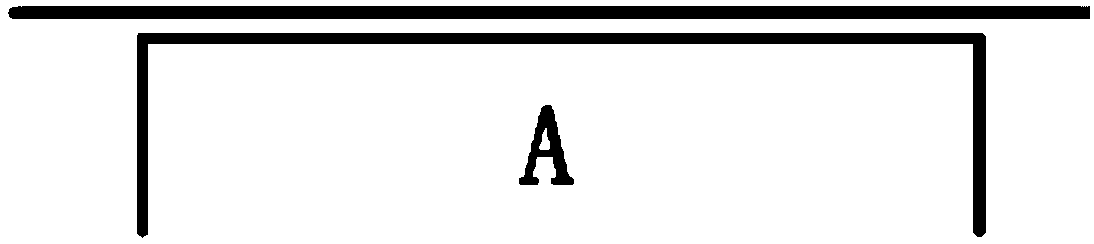

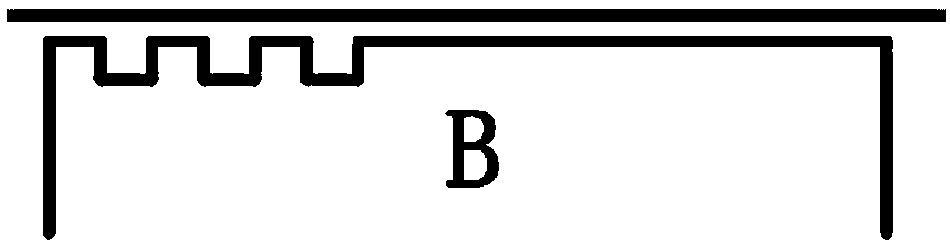

[0029] Please combine Figure 2 to Figure 4 As shown, the present invention discloses a stabilizing propelling bullet holder for an air cannon. The bullet holder is used in an air cannon and carries projectiles. The bullet holder includes a cylindrical bullet holder body, at least one annular groove is arranged on the outer surface of the bullet holder body, and the annular groove is circumferentially arranged on the bullet holder body.

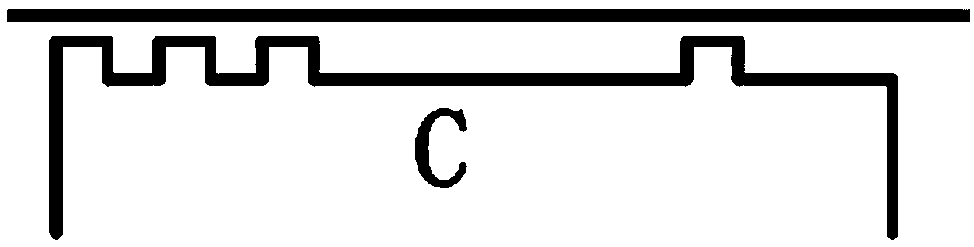

[0030] Specifically, as figure 2 , the flipper body 1 has three mutually parallel and evenly arranged annular grooves 2, and the width and depth of the three annular grooves 2 are the same. The bullet rest structure is numbered B structure in this embodiment. Such as image 3 There are four annular grooves parallel to each other on the bullet holder body 1', and the width and depth of two of the annular grooves 21' are the same, and the width of the other two annu...

Embodiment 2

[0033] This embodiment is an embodiment of the design method of the flick support structure.

[0034] Please combine Figure 6 Shown, the design method of air cannon in the present invention is used stably propelling bullet holder, comprises the following steps:

[0035] (1), given the initial design parameters, design several types of bullet holders, the number of grooves and groove widths on each type of bullet holder are different;

[0036] (2) Through the analysis, modeling, calculation and analysis of the gap leakage of several different types of bullet holders, the leakage of different bullet holders is obtained;

[0037] (3), comparing the leakage of each type of bullet holder, the type of bullet holder with the smallest leakage is used as the initial design configuration;

[0038] (4), setting the leakage index of the bullet holder of initial design configuration, as the initial target parameter of further iteration;

[0039] (5), given the design parameters of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com