Miniature array electromagnet mounting assembly

A micro-array, electromagnet technology, applied in the direction of assembling printed circuits, electrical components, electrical components, etc. with electrical components, can solve the problems of too many mechanical transmission links, the bulk of the whole machine, and the complex structure of the placement head.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

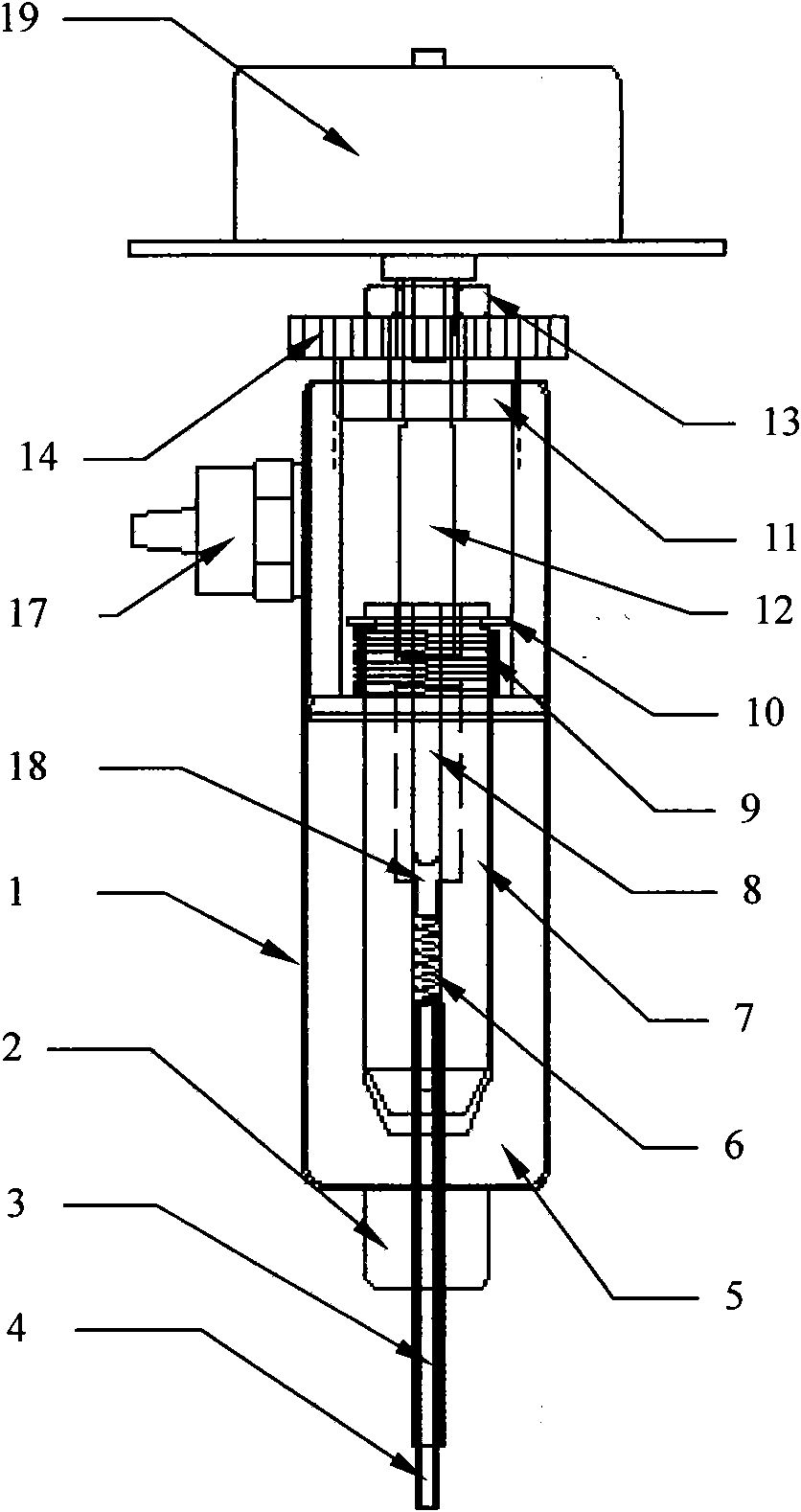

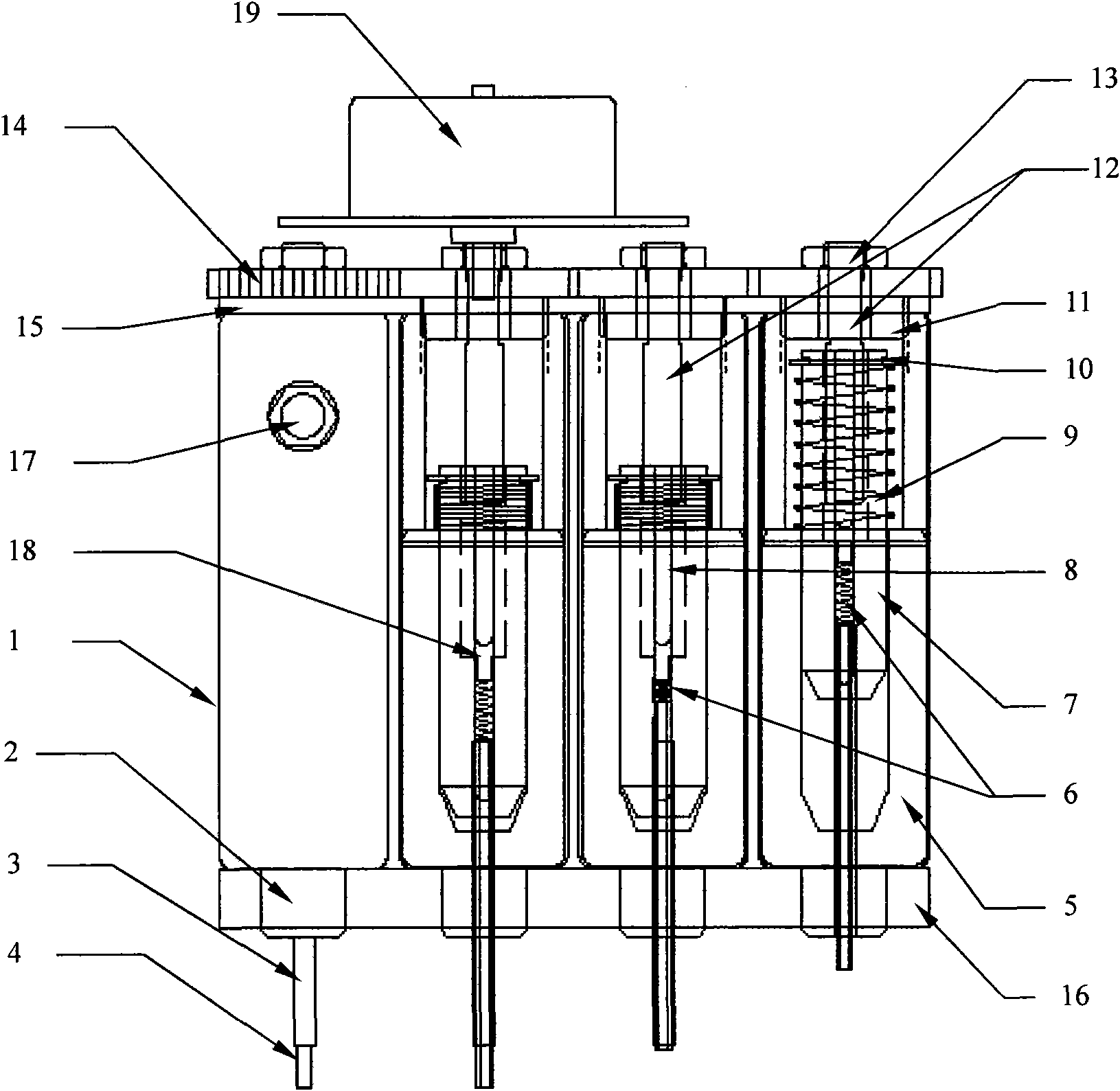

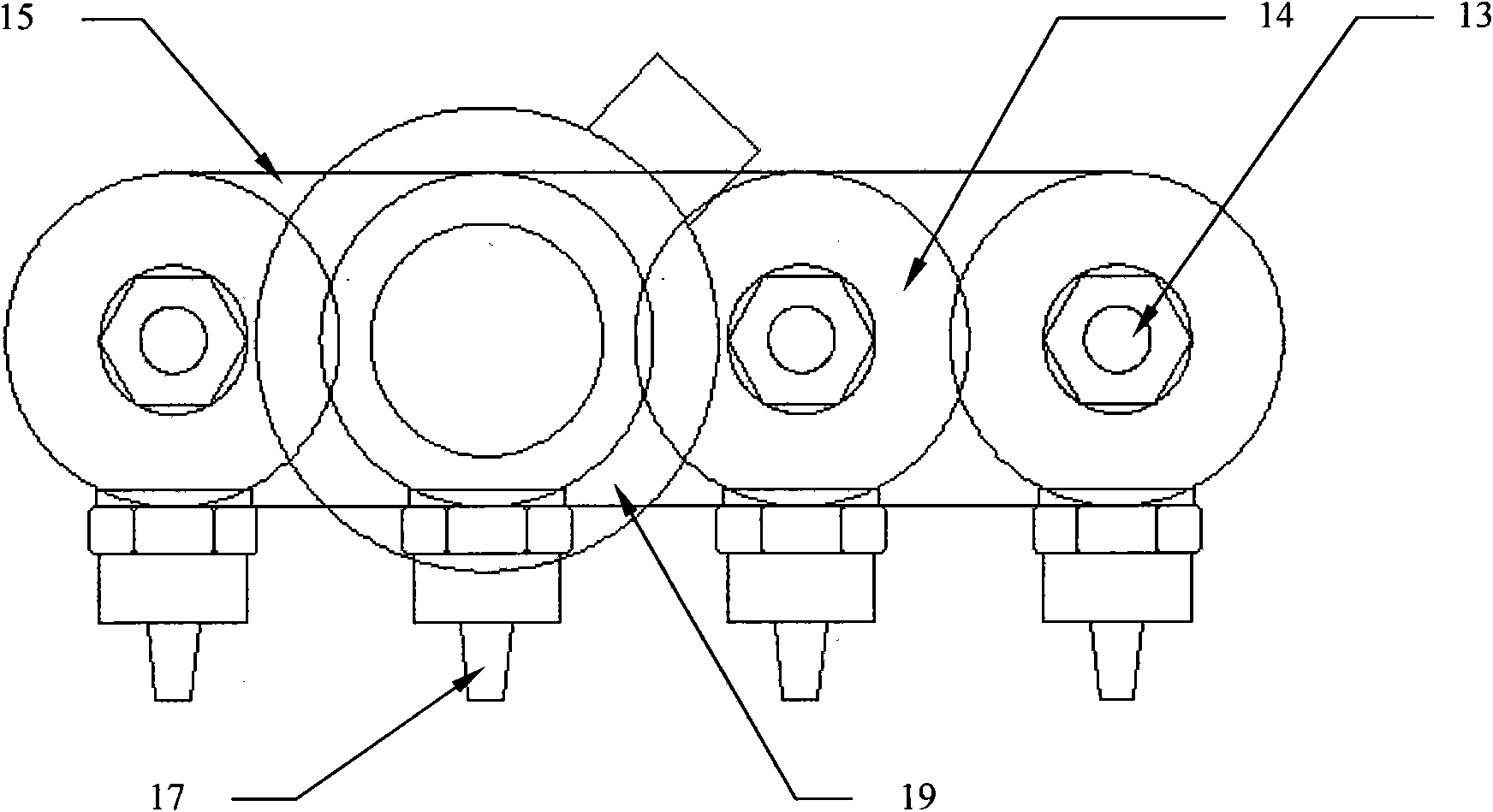

[0015] exist figure 1 A completed placement head is shown in . It takes the central axis of the cylinder body 1 as the axis, and sequentially installs the suction nozzle 4, the suction nozzle conduit 3, the suction nozzle buffer spring 6, the cylindrical slide iron 7, the slide iron return spring 9, the circlip 10, the cover 11, the through shaft 12. Gear 14, nut 13 and stepper motor 19, among which, there is a through hole 18 in the center of the cylindrical slide 7; the suction nozzle 4 slides in the suction nozzle duct 3, and the suction nozzle duct 3 and the cylindrical slide 7 are tightly fitted into one. The airflow enters from the suction nozzle 4 , enters the cylinder body 1 along the central through hole 18 of the cylindrical slide 7 , and is then drawn out from the suction nozzle 17 . The extended through shaft 12 of the stepping motor passes through the cover 11 on the cylinder body, and a metal pin is radially penetrated through the lower end of the through shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com