Aluminum silicon carbide packaging substrate and preparation method thereof

A silicon carbide sealing, silicon carbide ceramic-based technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc. The effect of not easy to slip teeth, not easy to crack and fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This embodiment provides an aluminum silicon carbide packaging substrate and a method for preparing the aluminum silicon carbide packaging substrate.

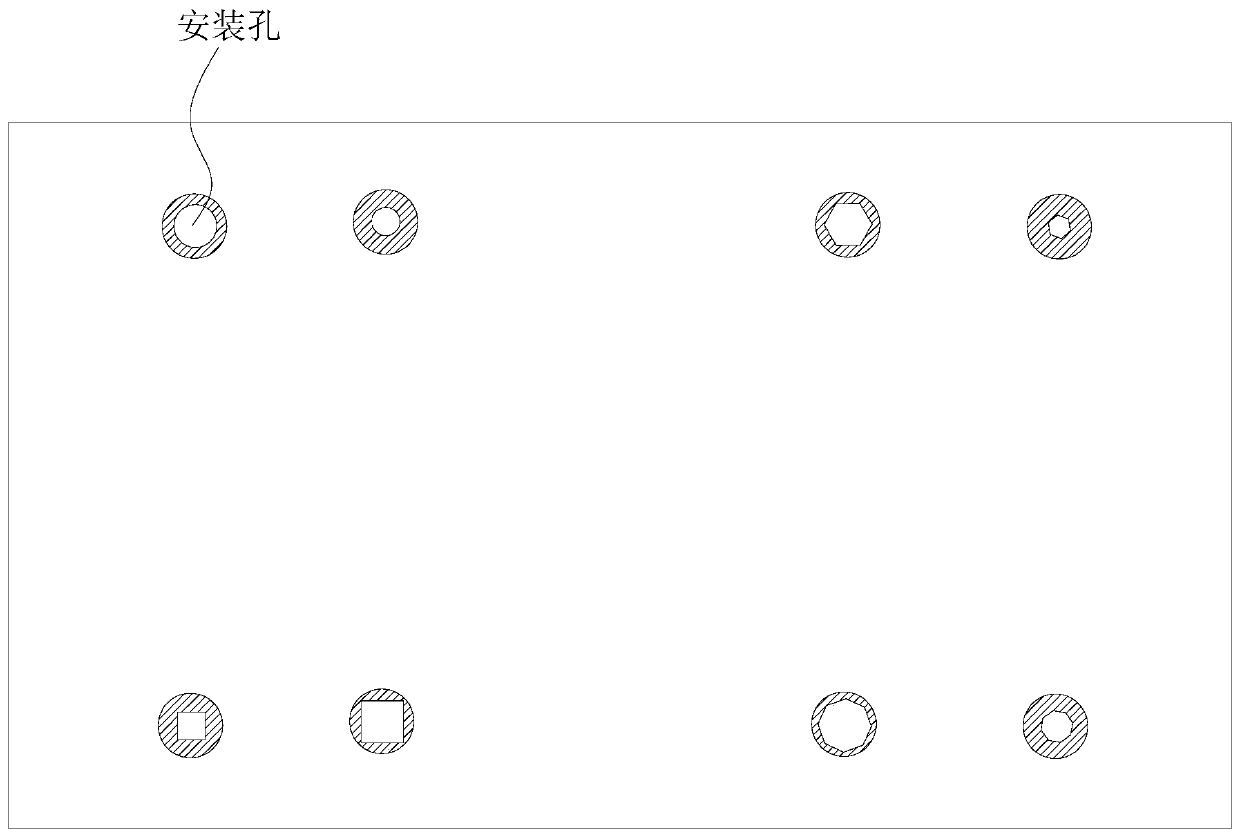

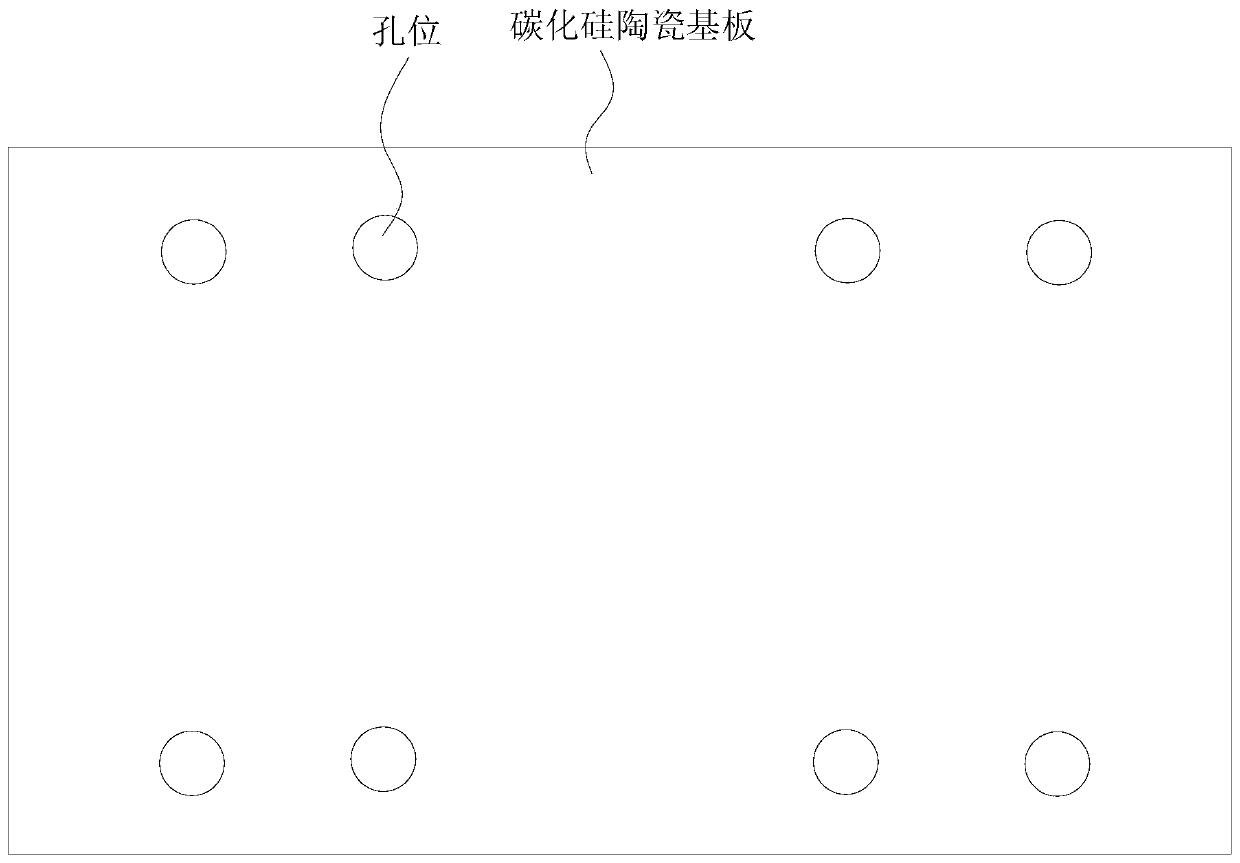

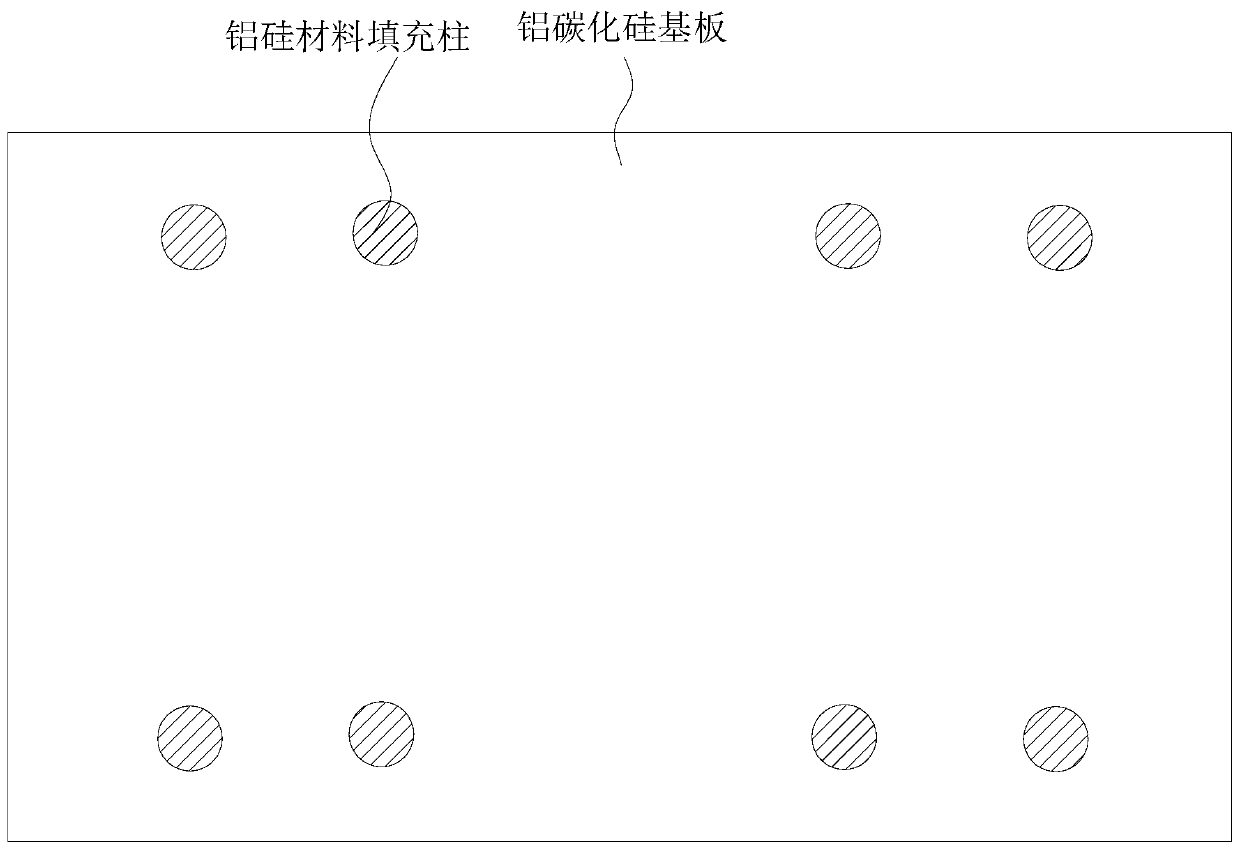

[0055] Such as figure 1 As shown, the aluminum silicon carbide packaging substrate of this embodiment includes an aluminum silicon carbide substrate with a hole position and an aluminum silicon material filled column embedded in the hole position, and each aluminum silicon material filled column is provided with a mounting hole, figure 1 The mounting holes shown in include four types of mounting holes: round, square, regular hexagon and regular octagon. In other embodiments, the outline shape of the aluminum silicon carbide package substrate and the shape, size and quantity of the mounting holes on it can be set according to the actual needs of the product. For example, the mounting holes can also be other regular polygons or irregular polygons. Step hole, countersunk hole or wire hole, etc., figure 1 It is only in a schemat...

Embodiment 2

[0073] This embodiment provides an aluminum silicon carbide packaging substrate with the same structure and mounting hole design as the aluminum silicon carbide packaging substrate described in Example 1. The preparation method of the aluminum silicon carbide packaging substrate of this embodiment is basically the same as the preparation method of the embodiment. The same, the difference is that in step 1, step 1 of this embodiment is: the four silicon carbide powder materials with particle diameters of 0.5-1μm, 20-25μm, 50-60μm, and 80-90μm are in turn according to the following mass percentages 10%, 10%, 20%, 60% are mixed uniformly to obtain powder M1.

Embodiment 3

[0075] This embodiment provides an aluminum silicon carbide packaging substrate with the same structure and mounting hole design as the aluminum silicon carbide packaging substrate described in Example 1. The preparation method of the aluminum silicon carbide packaging substrate of this embodiment is basically the same as the preparation method of the embodiment. The same, the difference is that in step 3, step 3 of this embodiment is: the four kinds of silicon powders with particle diameters of 4-6μm, 20-25μm, 50-60μm, 80-90μm are successively adjusted to the following mass percentages of 20% , 45%, 15%, and 20% are mixed uniformly to obtain powder M3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com