Split metering valve

A metering valve and split-type technology, which is applied in the field of mechanical hydraulic control, can solve the problems of high matching requirements, low assembly efficiency, and difficult processing, and achieve the effects of reducing the difficulty of matching, improving assembly efficiency, and reducing the difficulty of machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

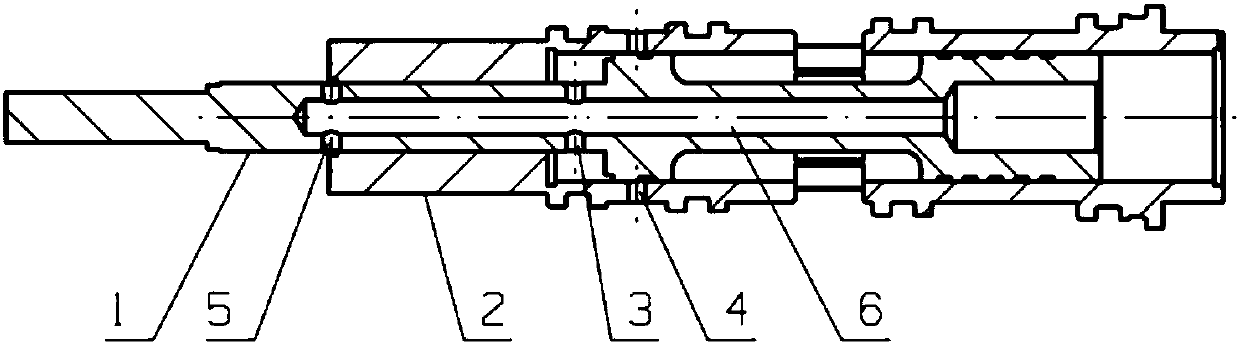

[0017] The function of the metering valve in the prior art is command control and fuel metering, and consists of a valve 1 and a bushing 2 . The valve 1 is set in the bushing 2, the axial length of the valve 1 is 130mm, and the axial length of the bushing 2 is 105mm. The gap between valve 1 and bushing 2 is required to be 0.008-0.014mm. The valve 1 is provided with a servo fuel inlet hole 3, an orifice 5 and a servo oil passage 6, and the bush 2 is provided with a servo fuel inlet hole 4, which cooperate to realize the command control function.

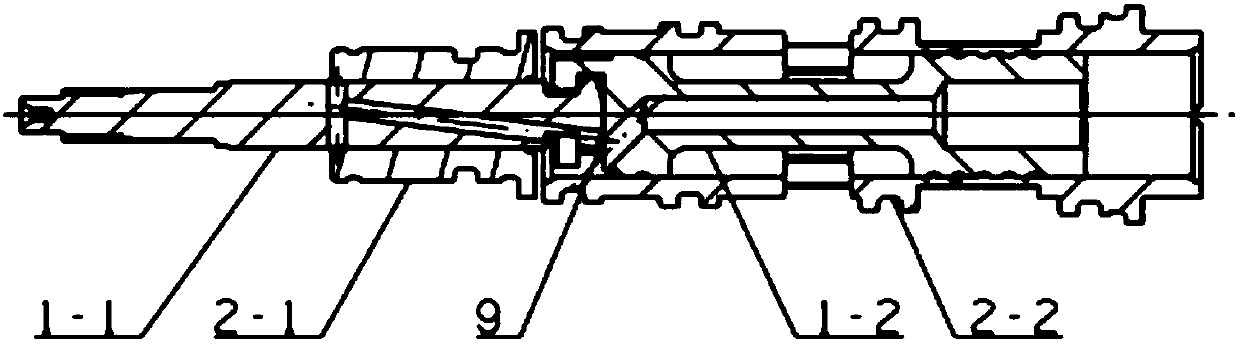

[0018] The invention provides a split metering valve, which divides the valve 1 into two parts, the valve 1-1 and the valve 1-2. The division of the valve 1 follows two principles: first, it is divided according to the function of the valve 1; second, it is divided proportionally according to the axial length of the valve 1.

[0019] The valve 1 is divided into two parts at the servo fuel inlet hole 3, the valve 1-1 is used for comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com