Processing technique of new steel plate hoe

A processing technology and steel plate technology, which is applied in the processing technology field of new steel plate hoes, can solve the problems of rough product surface and insufficient aesthetics, and achieve the effects of reducing machining allowance, labor intensity of workers, and easy control of process conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

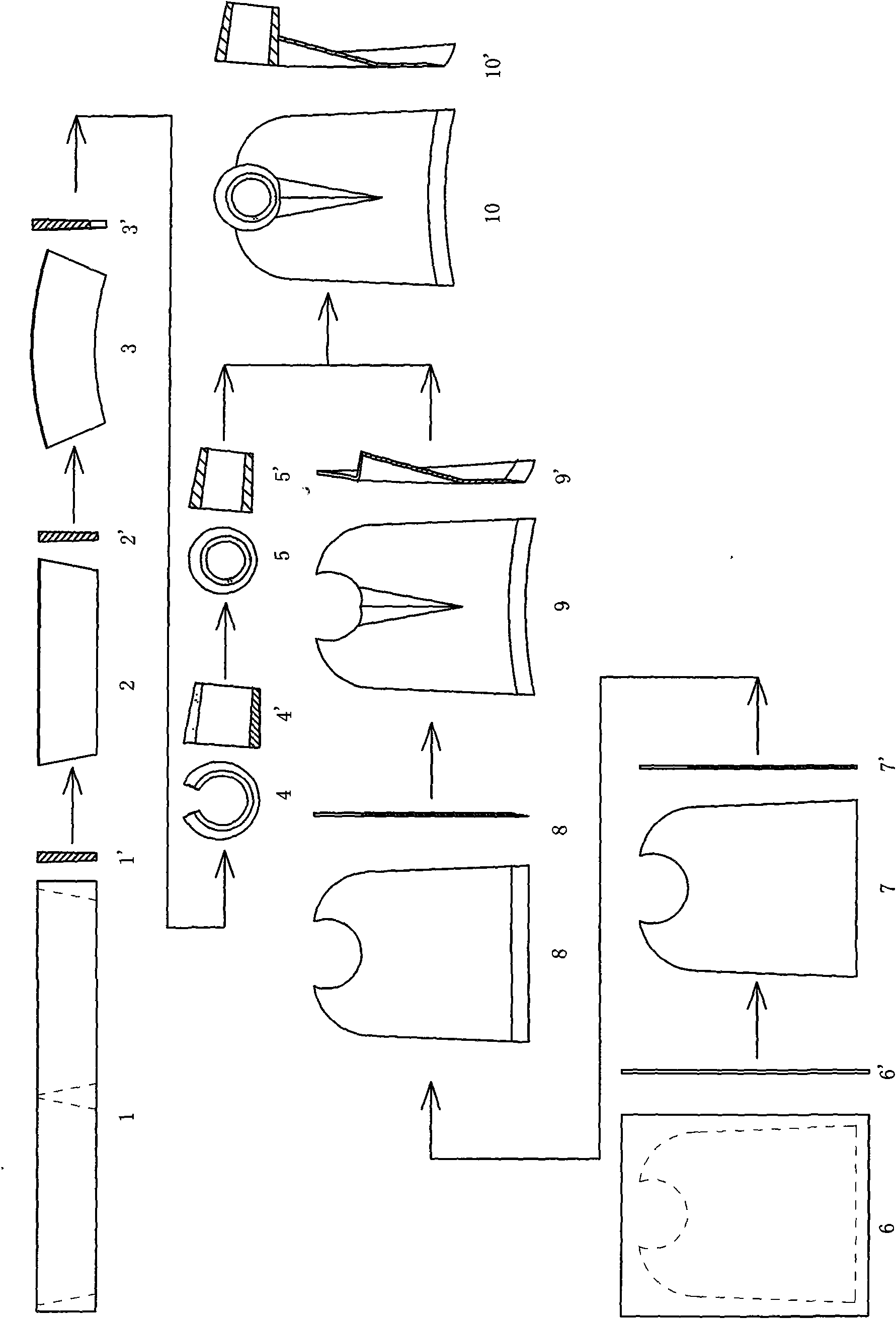

[0018] attached figure 1 The processing flow chart of a new type of steel plate hoe is to use strip steel and bar steel to punch out mechanically, and then mechanically mold them into a hoe plate and a hoe plate, and the hoe plate and hoe plate are combined by welding; the specific steps are:

[0019] A. Production of hoes

[0020] Firstly, the bar steel 1 with trapezoidal cross-section is blanked with a punching machine or cutting equipment, and the result is a long trapezoidal strip 2 with a thick end and a short side; the side of the long trapezoidal strip 2 is pressed into an arc by a hydraulic press and a mold shape of the long trapezoidal strip 3; then use the hydraulic press and the bending and winding mold twice to wind the arc-shaped long trapezoidal strip 3 into a tapered sliver 4; Welding of the winding seam, get hoe Weng 5;

[0021] B. Production of hoe boards

[0022] First place the strip steel 6 on the mold of the punching machine to punch out the flat blank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com