Compression wave generation system of cooling machine with compressor of constant oil lubricating flow

A generation system and compressor technology, applied in refrigerators, compressors, refrigeration and liquefaction, etc., can solve the problems of high production cost of plane rotary valve, easy saturation of oil filter system, poor reliability, etc., to reduce the difficulty of machining, The effect of reducing friction loss and simplifying structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

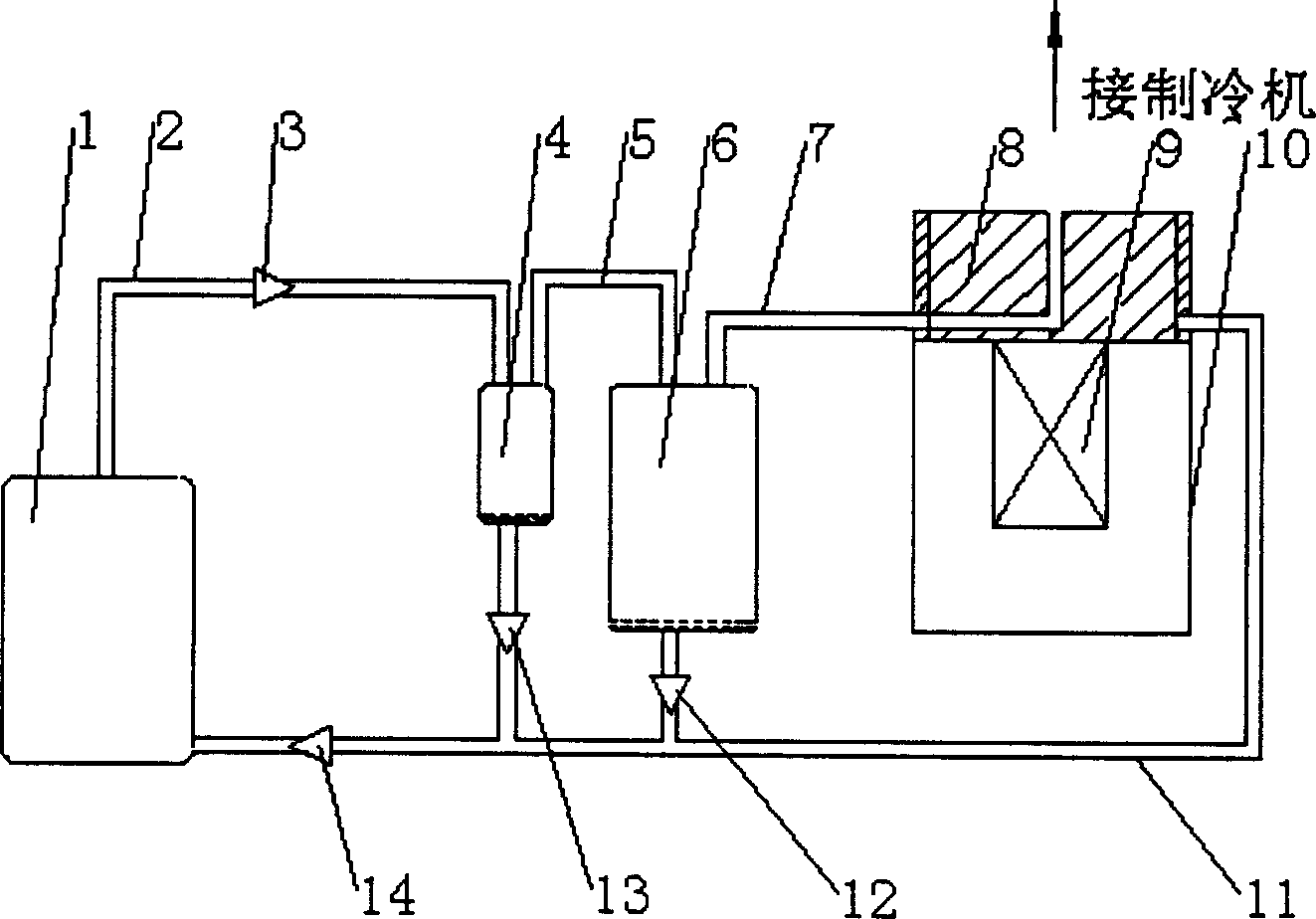

Embodiment 1

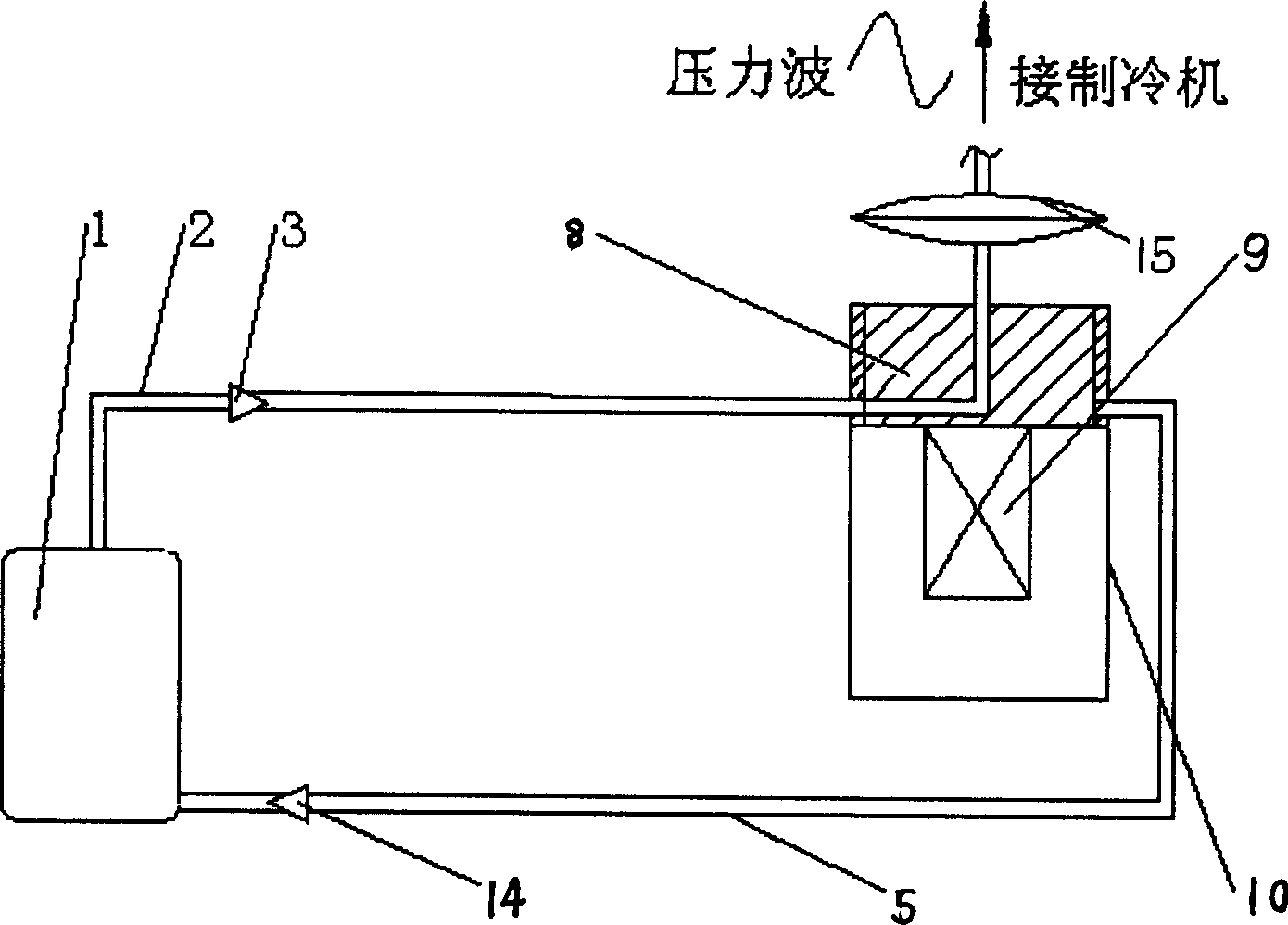

[0022] Such as figure 2 As shown, the pressure wave generation system for a GM refrigerator provided by the present invention includes: a valve-type piston compressor driven by a rotating motor connected in sequence and forming a loop 1, a first oil and gas pipeline 2 and the The first one-way valve 3, the planar rotary valve 8 installed between the rotating electric machine 9 and the refrigerator, the second oil and gas pipeline 5, and the fourth one-way valve 14. Between the plane rotary valve 8 and the refrigerator is installed an elastic membrane 15 made of a Viton brand fluororubber material produced by DuPont in the United States.

[0023] The lubricating oil installed at the bottom of the compressor 1 is compressed by the compressor and enters the plane rotary valve 8 with the gas to make it well lubricated. The lubricating oil accumulated in the valve returns to the compressor with the gas when the refrigeration system is low in pressure. , And repeat the cycle.

[0024] ...

Embodiment 2

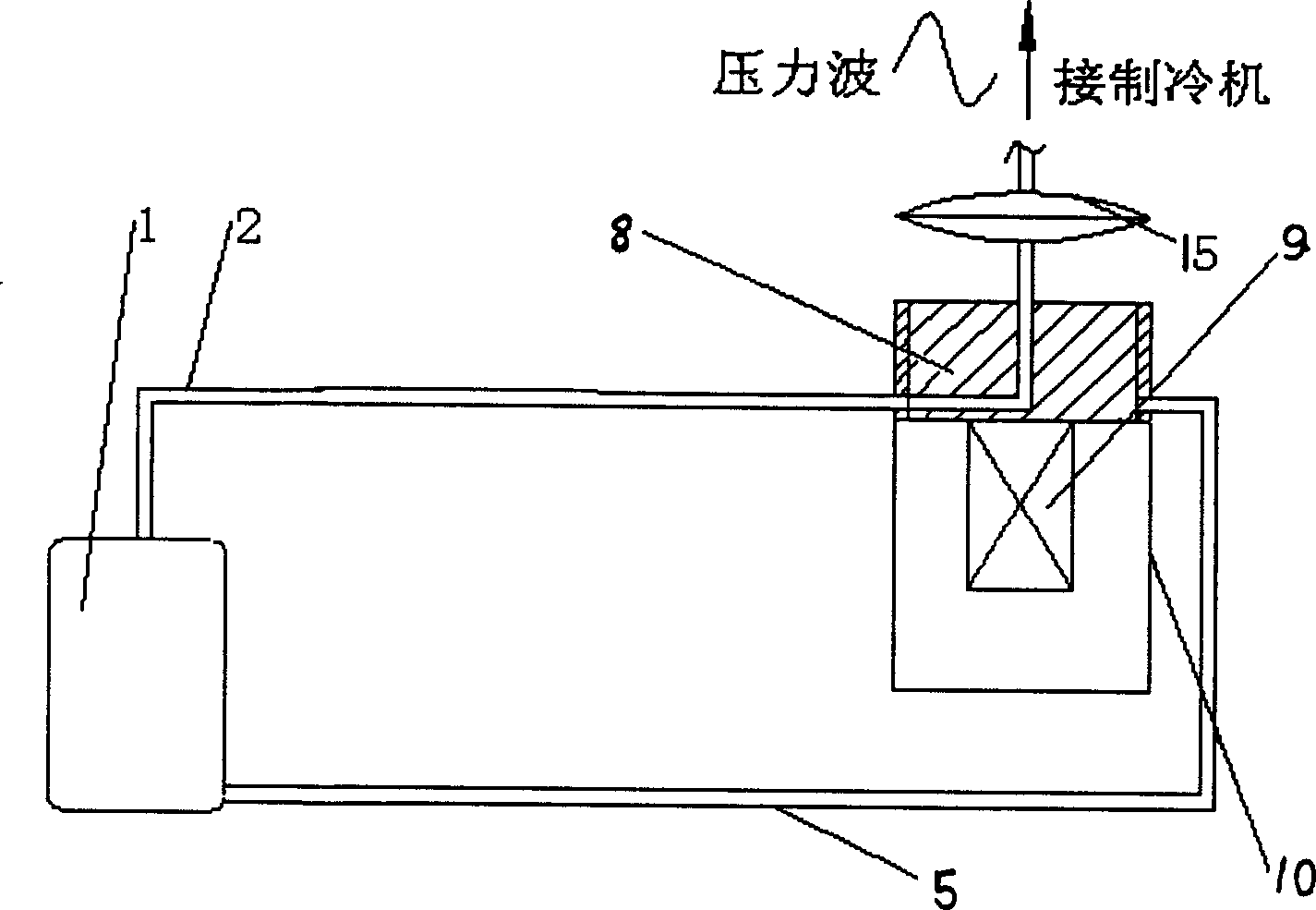

[0027] Such as image 3 As shown, the pressure wave generation system for a GM refrigerator provided by the present invention includes: a screw compressor 1, a first oil and gas pipeline 2, which is installed between the rotating electric machine 9 and the refrigerator, which are sequentially connected and form a loop Plane rotary valve 8, second oil and gas pipeline 5. An elastic membrane 15 made of beryllium bronze is installed between the plane rotary valve 8 and the refrigerator.

[0028] The lubricating oil installed at the bottom of the compressor 1 is compressed by the compressor and enters the plane rotary valve 8 with the gas to make it well lubricated. The lubricating oil accumulated in the valve returns to the compressor with the gas when the refrigeration system is low in pressure. , And repeat the cycle.

[0029] The planar rotary valve 8 is driven by the rotating electric machine to alternately communicate the connecting pipe of the refrigerator with the high and low ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com