Annular circulation continuous vacuum coating device

A vacuum coating and ring-shaped technology, which is applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., can solve the problem of increasing production cost, production time and production space, increasing the difficulty and cost of fault maintenance, and increasing the Problems such as the difficulty of workpiece transmission can achieve the effects of reducing equipment costs and maintenance costs, strong replaceability, and reducing the difficulty of machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

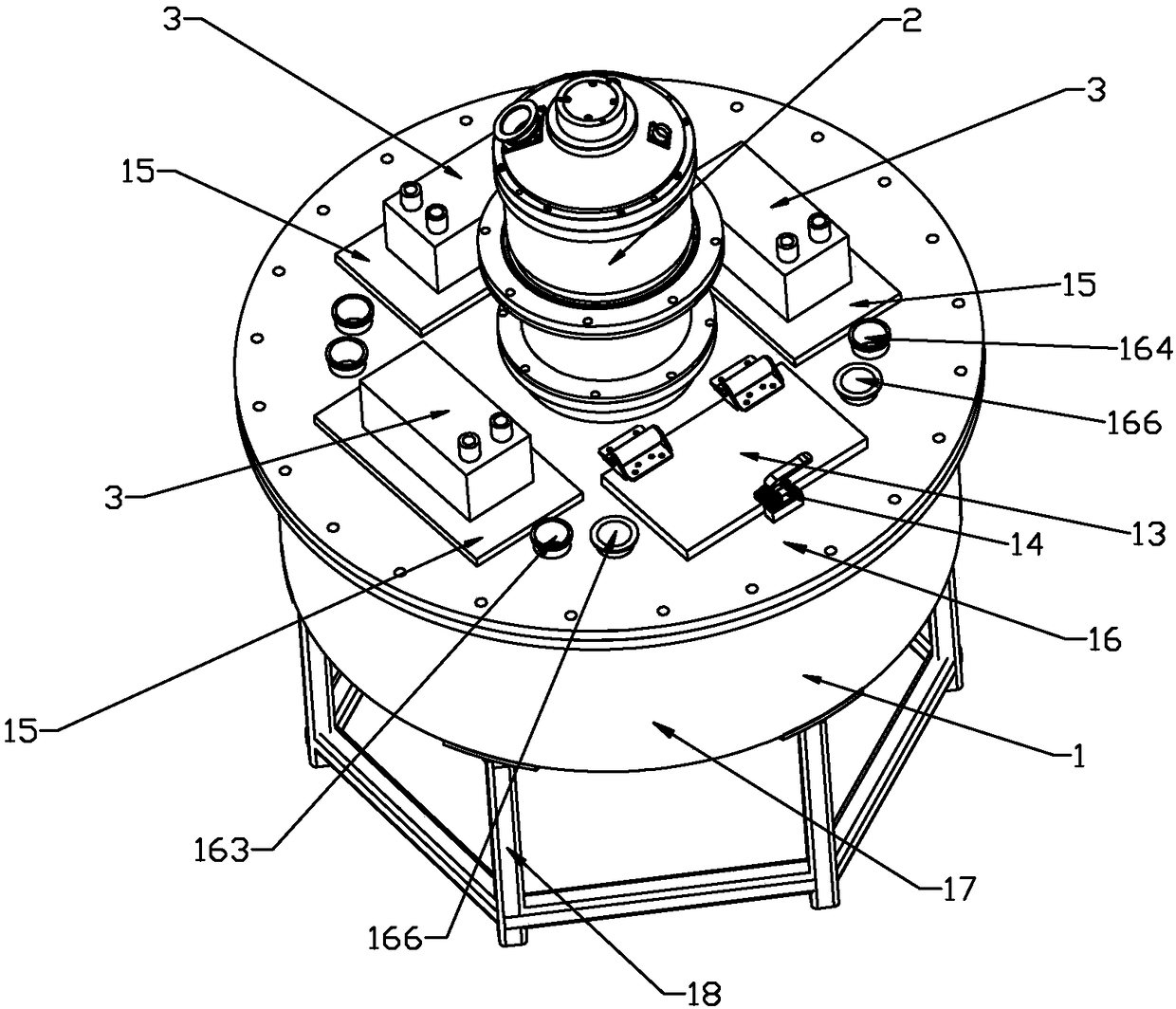

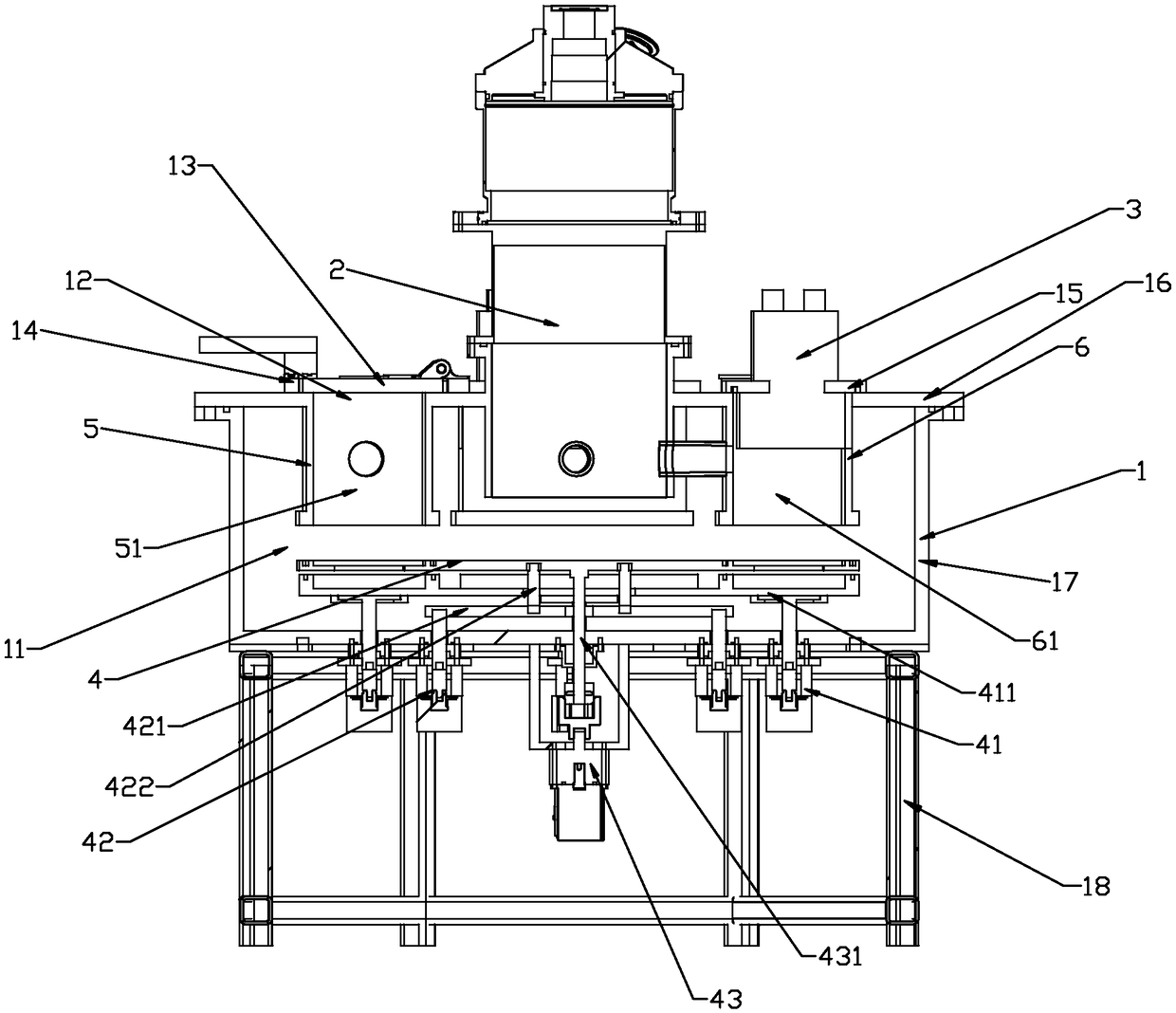

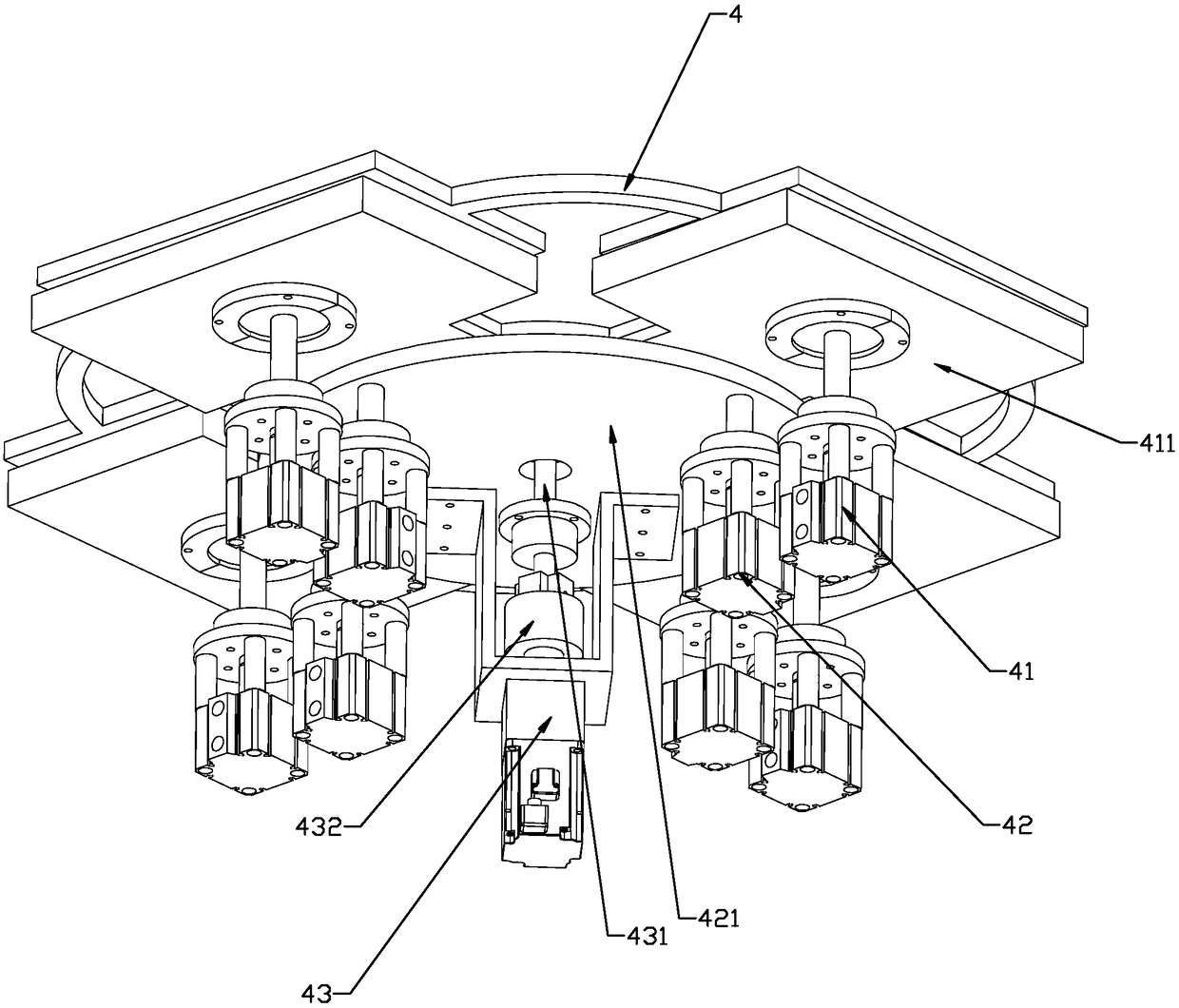

[0028] In order to make the purpose, technical solutions and advantages of the present invention clearer, below in conjunction with embodiment and accompanying drawing, the present invention is described in further detail:

[0029] For the convenience of description, in the present invention, the obtaining of vacuum and restoring the atmosphere of the vacuum device are briefly described.

[0030] The vacuum device is welded and assembled with structural metal carbon steel, stainless steel, etc. In order to obtain the required vacuum degree, it is necessary to install an exhaust system on the vacuum device. Generally, the exhaust system is divided into two parts: a rough pumping system and a fine pumping system. The rough pumping system generally consists of a mechanical pump with a high pumping speed, a Roots pump, and a backing valve controlled by a cylinder and a solenoid valve. The fine pumping system includes one or more sets of high vacuum pumps and the backing pump unit o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com