Method for winding and forming rough yarn after bobbiner is full of yarn

A technology of roving frame and full yarn, applied in spinning frame, continuous winding spinning frame, intermittent winding spinning frame, etc., can solve problems such as yarn falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

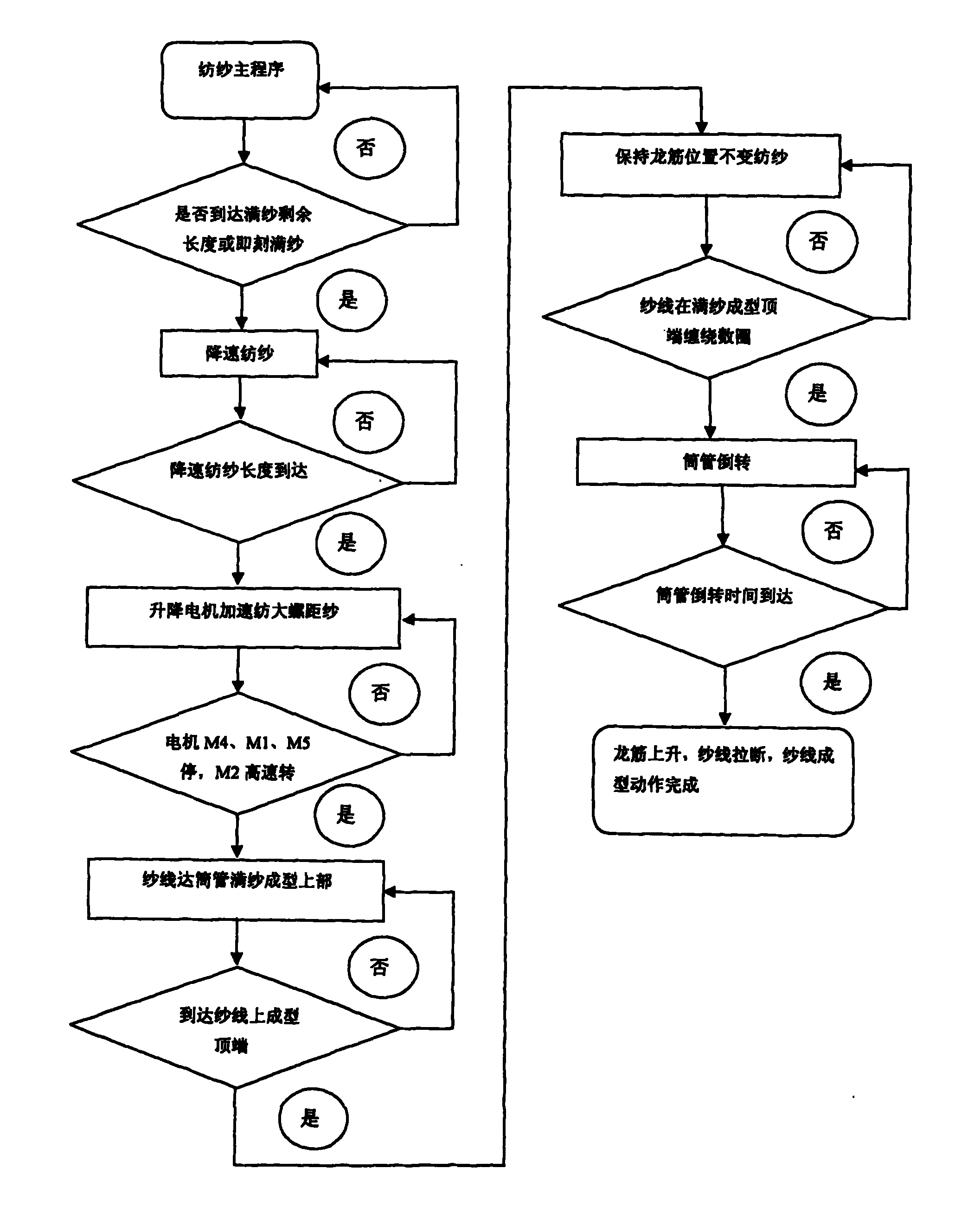

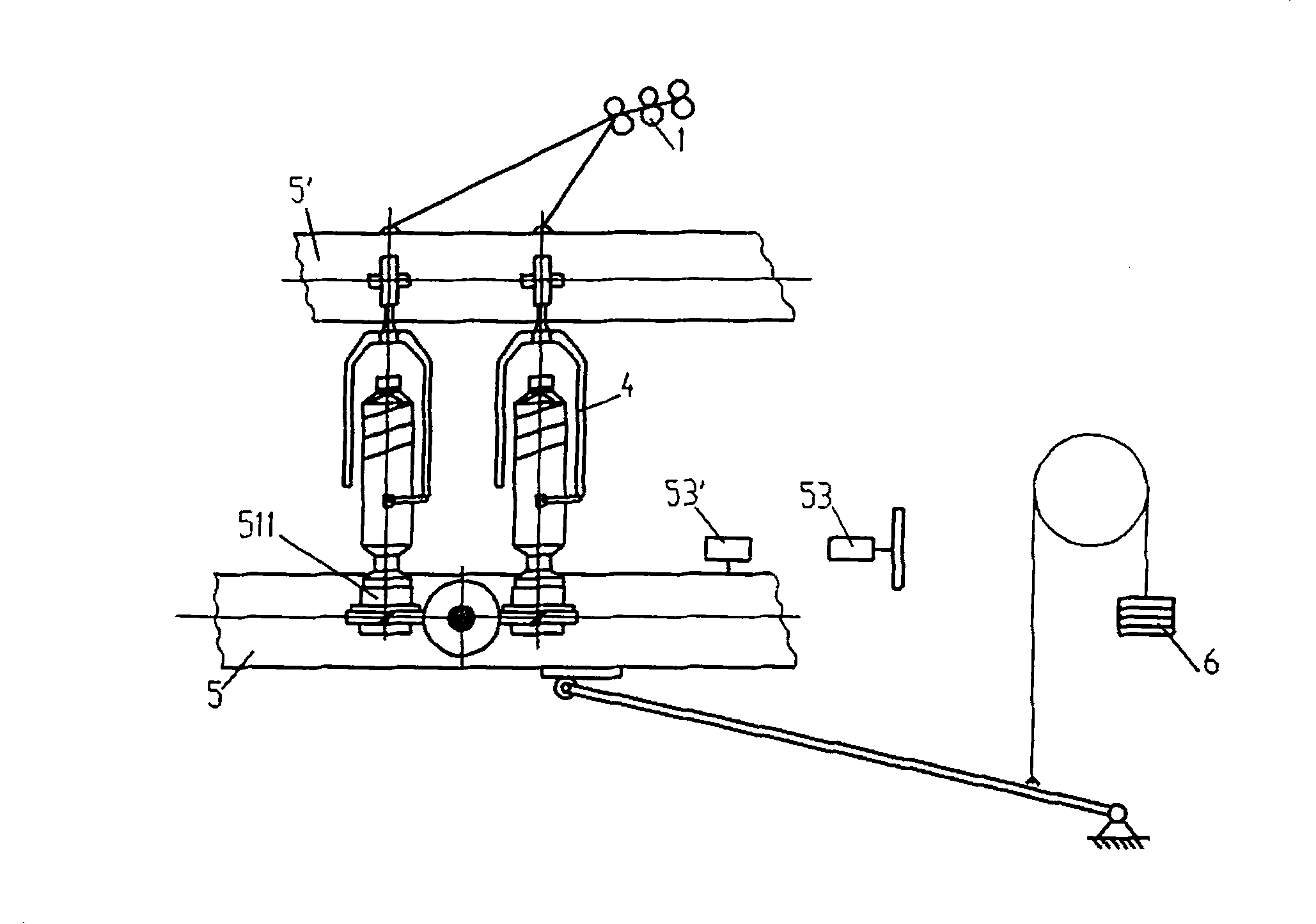

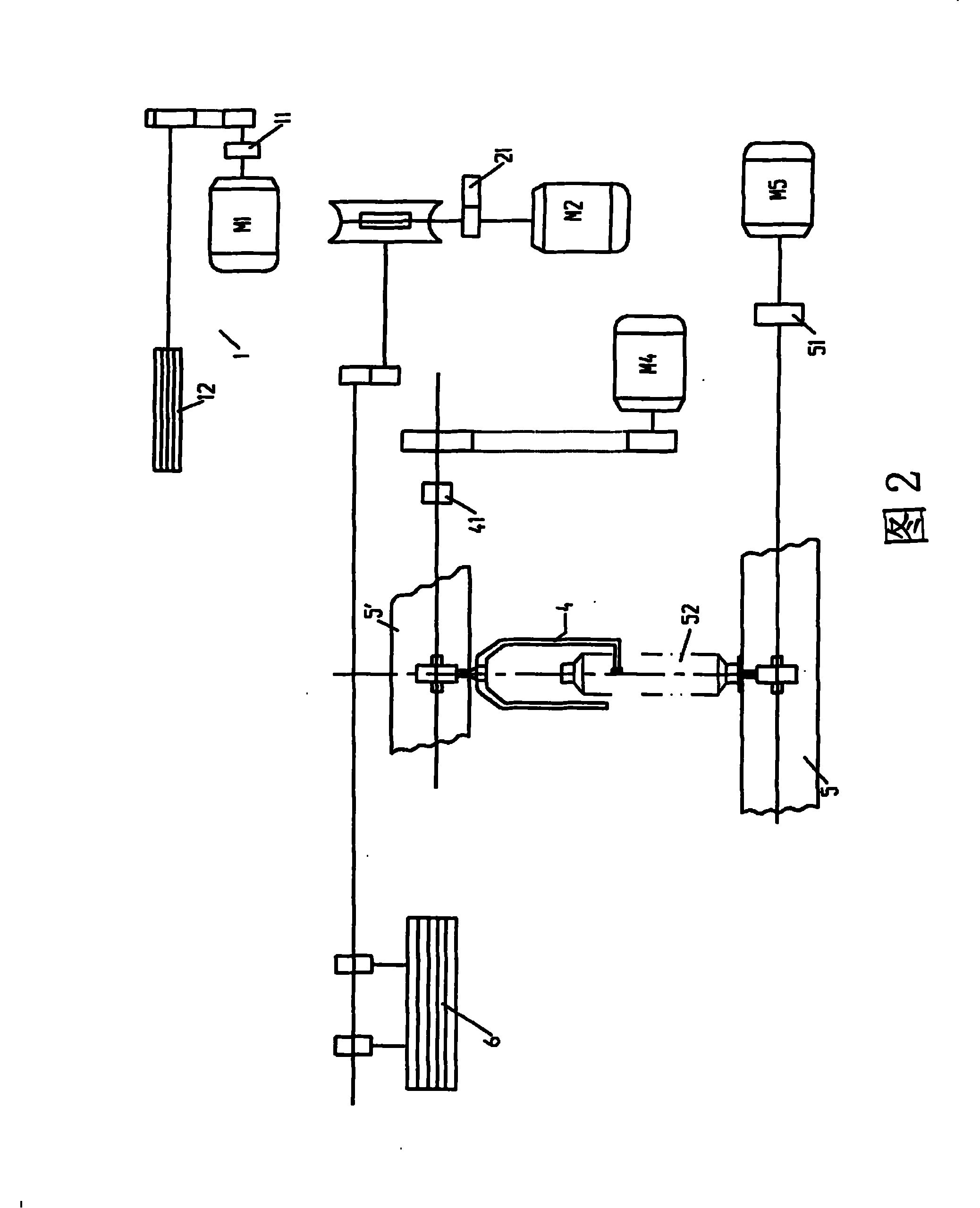

[0023] refer to figure 1 As shown, the device for winding and shaping the roving after the roving frame is full of yarn in the present invention is arranged on the roving frame, including a main control unit 2, a programmable logic controller (PLC), and a plurality of variable speed control devices 61, 62, 64 and 65, the flyer 4, the lower dragon rib 5 and a plurality of detection devices 11, 21, 41, 51 and 53; the lower dragon rib 5 is provided with a bobbin rotating body 511, which is equipped with the aforementioned spindle The bobbin 52 that the wing 4 is matched with;

[0024] The draft detection unit 1 is composed of a draft device 12 driven by a motor M1 and a detection device 11 connected to the draft device 12; the detection device 11 is connected to the main control unit 2 and sends a speed signal;

[0025] The variable speed control devices 61, 62, 64, 65 drive the motors M1, M2, M4, M5 respectively, and are connected with the main control unit 2 and a programmabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com