Method for operating a textile machine and textile machine

A technology of textile machines and spinning machines, which is applied in spinning machines, open-end spinning machines, textiles and papermaking, etc., and can solve problems such as complicated processes and disadvantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

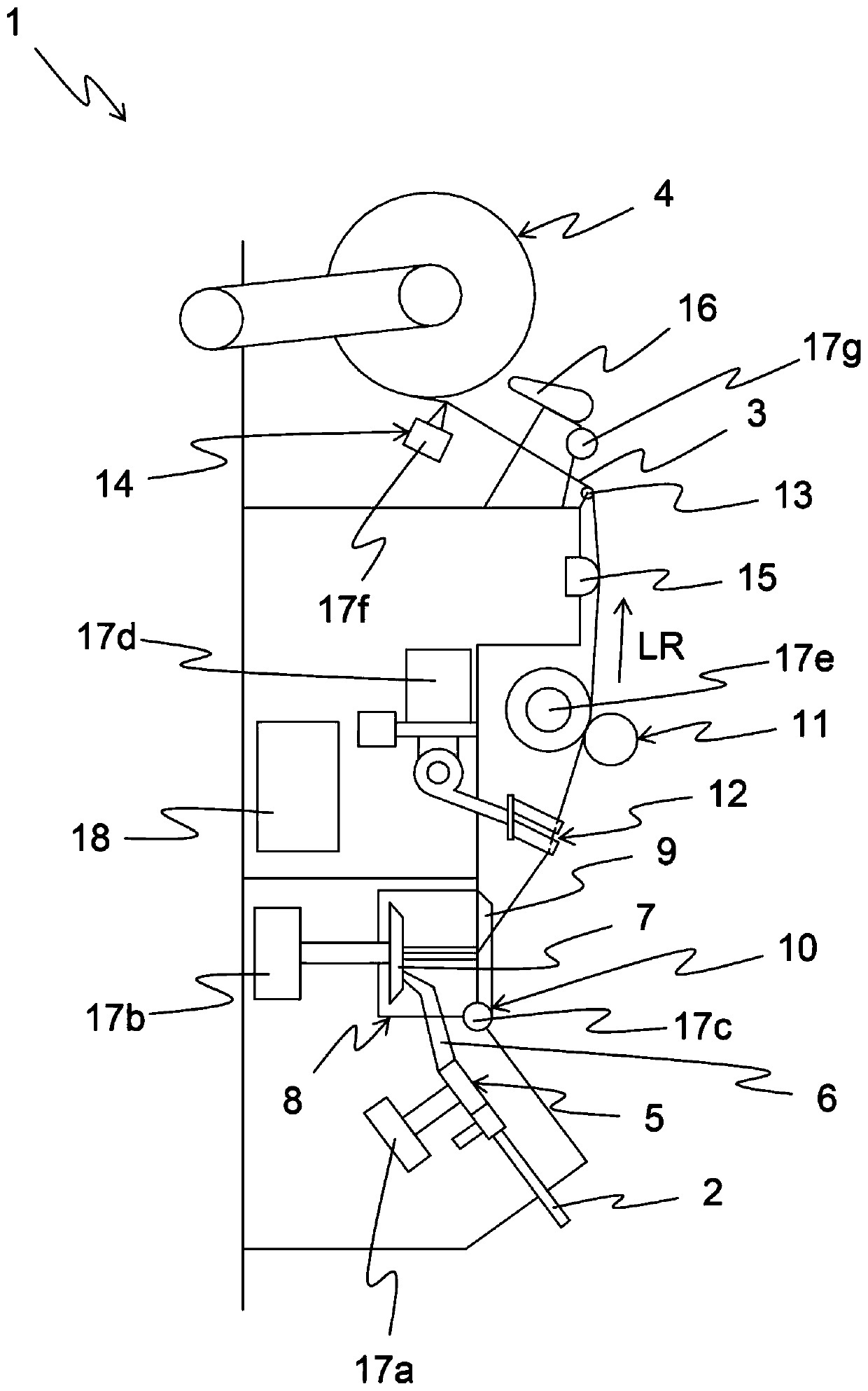

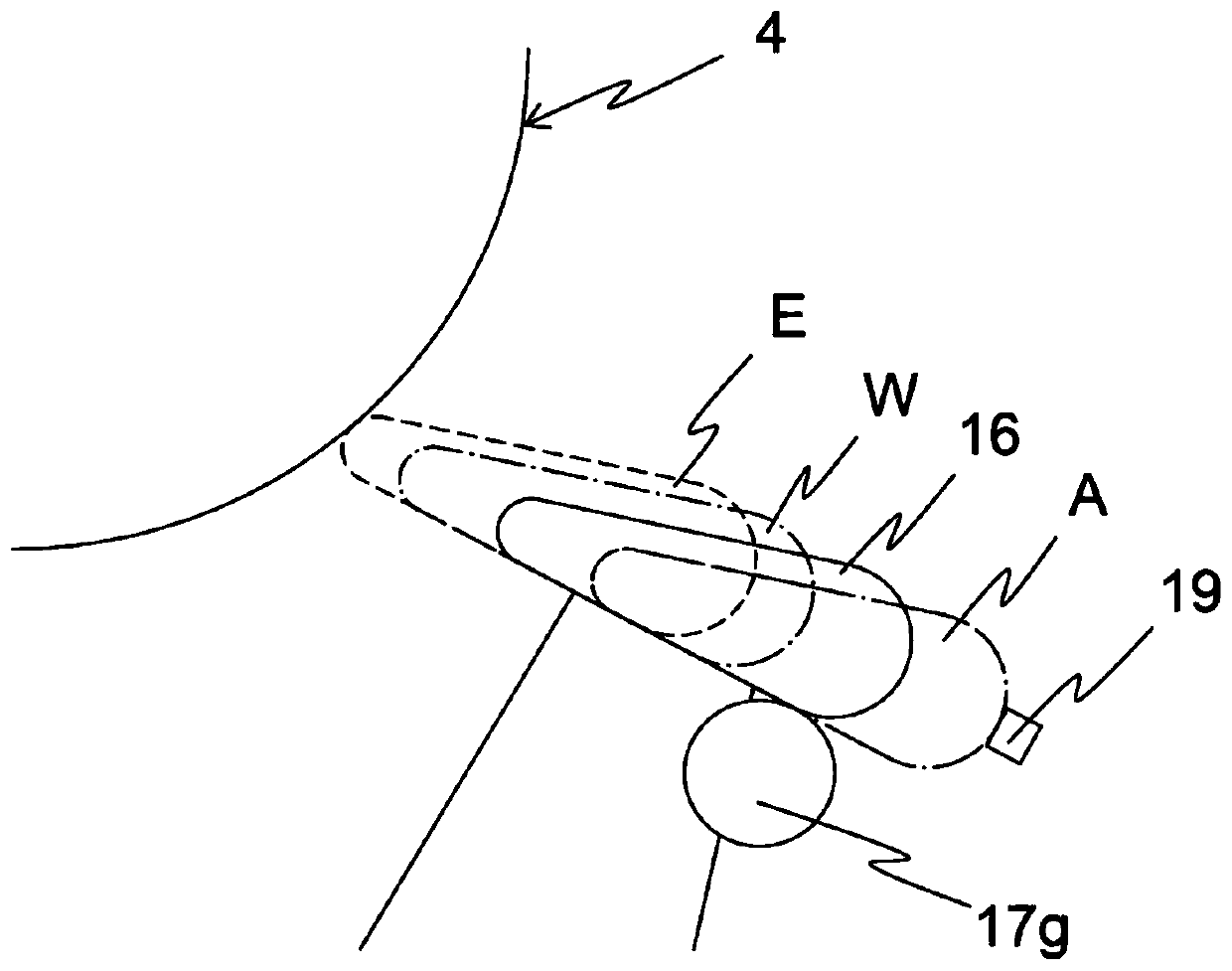

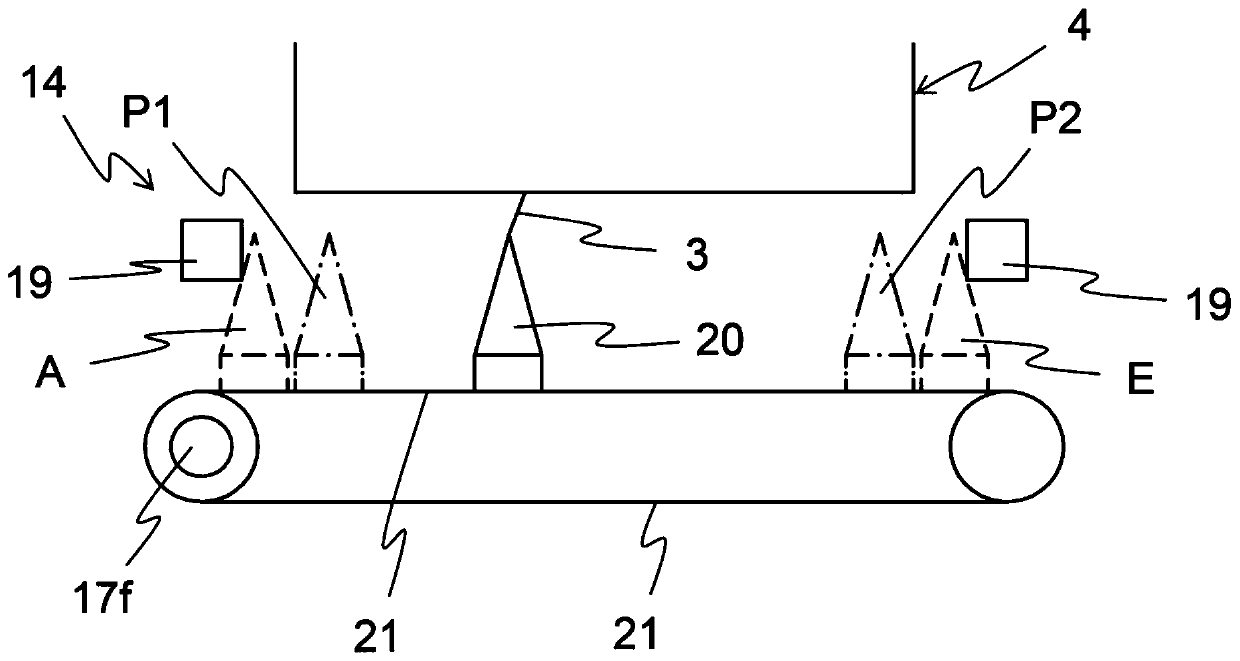

[0026] figure 1 A schematic side view of station 1 of the textile machine is shown. The textile machine may comprise a plurality of stations 1 in order to increase the productivity of the textile machine according to the number of the stations 1 . In the present embodiment, station 1 is configured as a spinning station of a rotor spinning machine. However, the invention is applicable in principle to any textile machine, in particular other open-end spinning machines, air-jet spinning machines or eg winders.

[0027] Station 1 produces yarn 3 from fiber strip 2 . The wire 3 passes through the station 1 in the feeding direction LR and is finally wound onto the reel 4 .

[0028] First, however, the fiber ribbon 2 is dispersed into its individual fibers 6 in the dispersing unit 5 . The individual fibers 6 are led to a spinning rotor 7 which produces the yarn 3 from the individual fibers 6 . In the present embodiment, the spinning rotor 7 is arranged in a spinning box 8 which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com