Mule spinning machine

The invention relates to a spinning frame and frame technology, which is applied to a walking frame spinning frame. field, it can solve the problems of high labor intensity, difficult operation, heavy weight, etc., and achieve the effect of reducing labor intensity and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

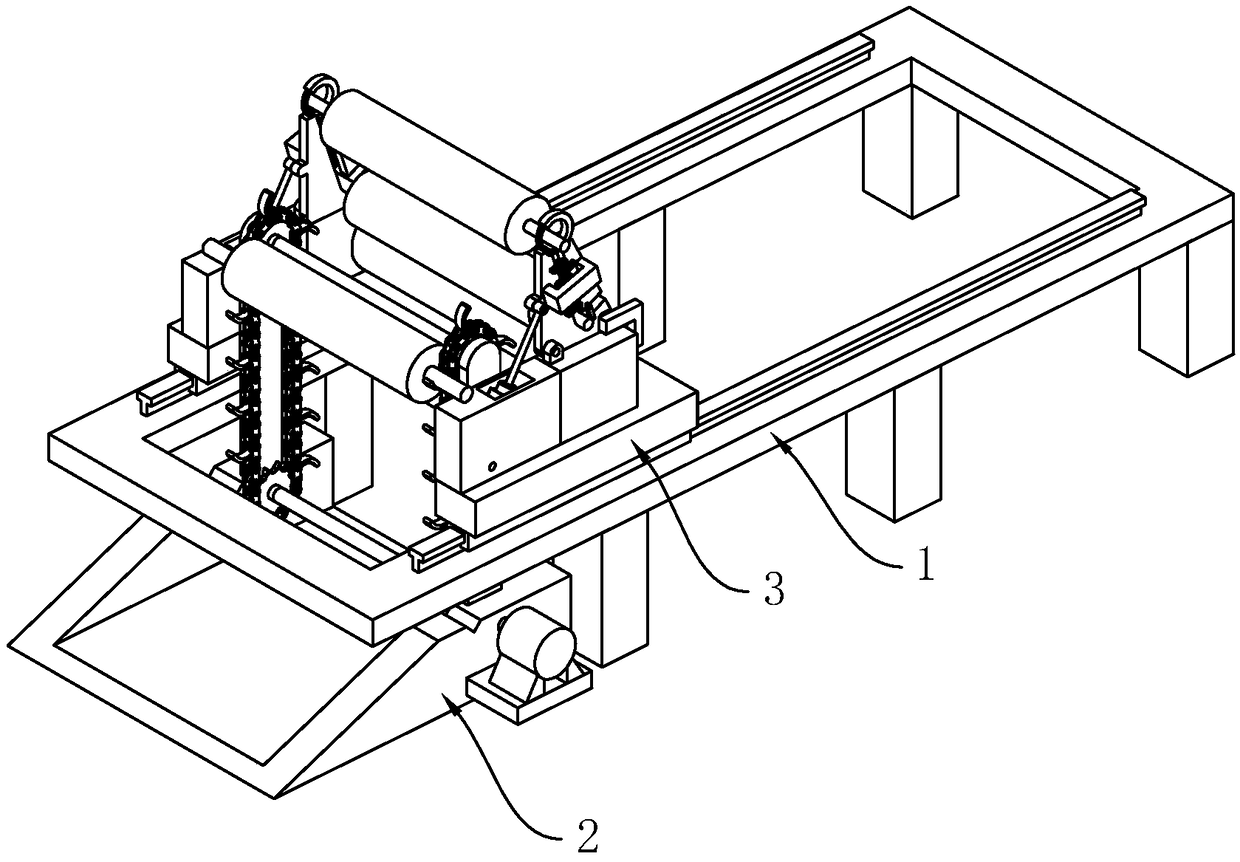

[0035] Embodiment: a kind of walking frame spinning machine, combines figure 1 , including a frame 1, one end of the frame 1 is fixedly connected with a lifting component 2, and a walking frame 3 is slidably connected with the frame 1.

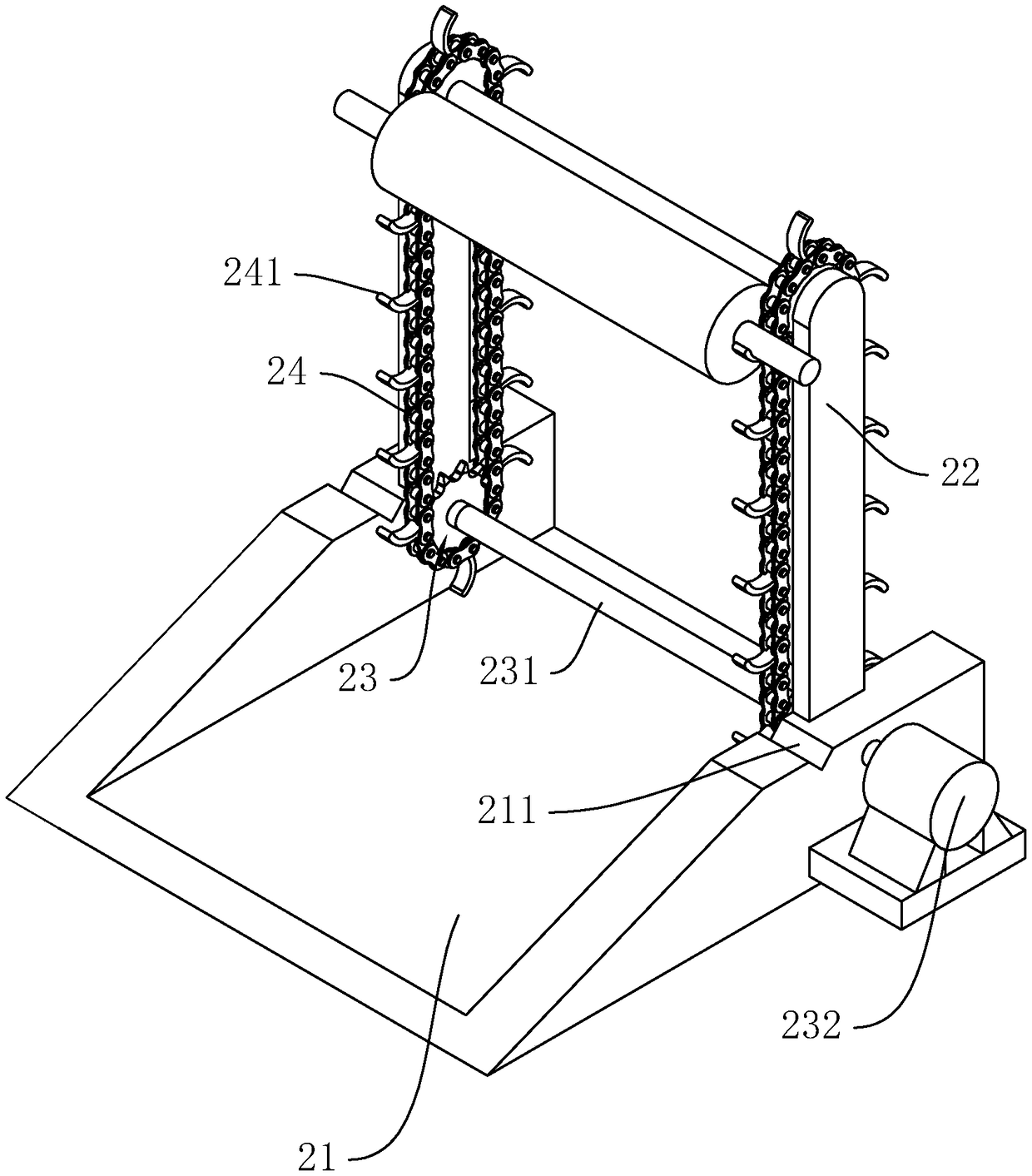

[0036] combine figure 2 The lifting assembly 2 includes a base 21, the length direction of the base 21 is the same as the length direction of the walking frame 3, the two ends of the base 21 are vertically fixedly connected with two vertical plates 22, and the sides of the two vertical plates 22 that are close to each other are respectively rotatably connected with Two vertically arranged sprockets 23, the axes of the sprockets 23 are all set horizontally, and the axes of the sprockets 23 of the two vertical plates 22 are all in the same vertical plane, and the lower side sprockets 23 of the two vertical plates 22 are fixedly connected with Transmission shaft 231, the lower end sprocket wheel 23 of one side vertical plate 22 is also provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com