Individual-spindle-drive type textile machine

A drive type, spindle technology, applied in spinning machine, single motor speed/torque control, motor generator control, etc., can solve the problems of unstable twisting, voltage drop of power supply bus, unstable rotary drive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

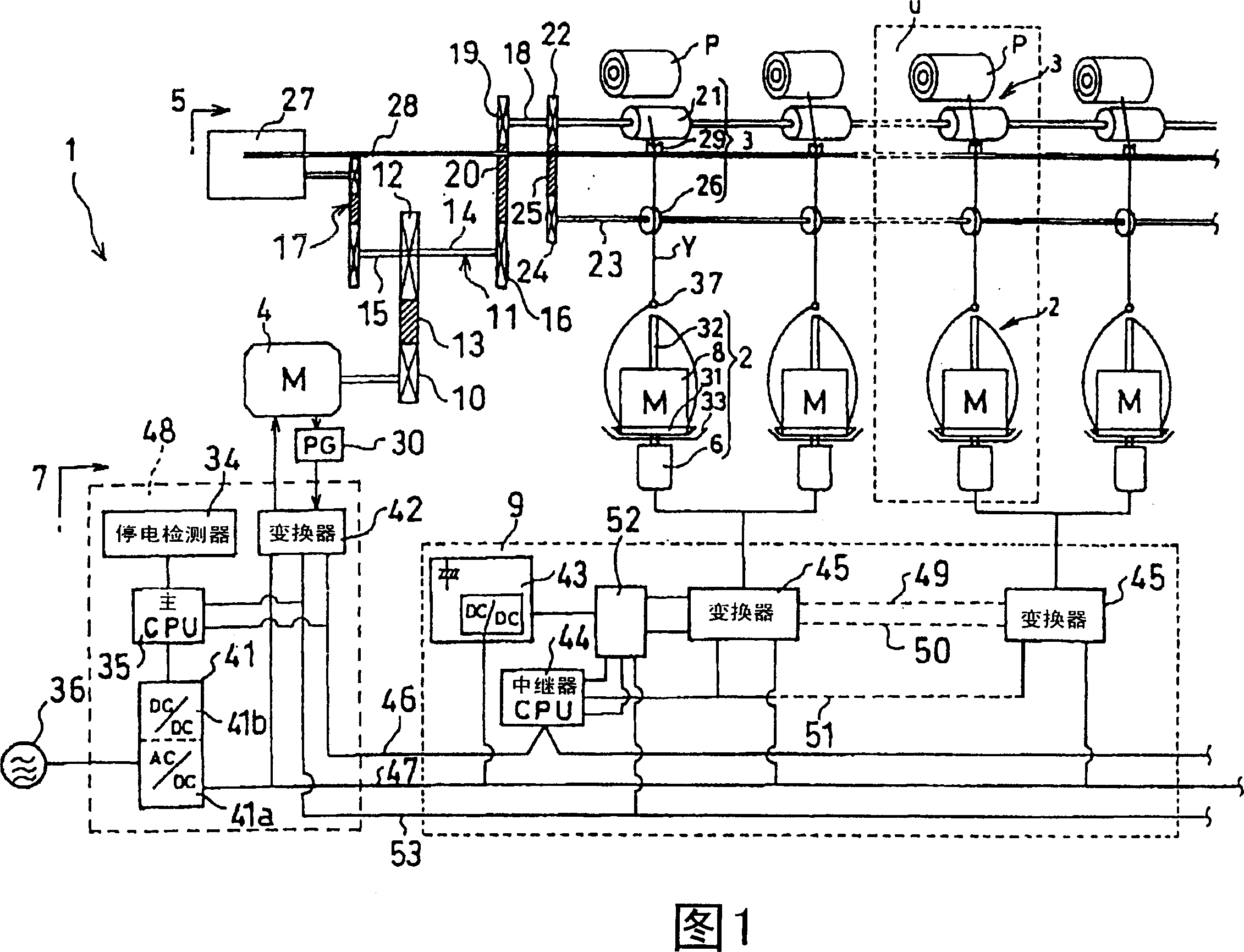

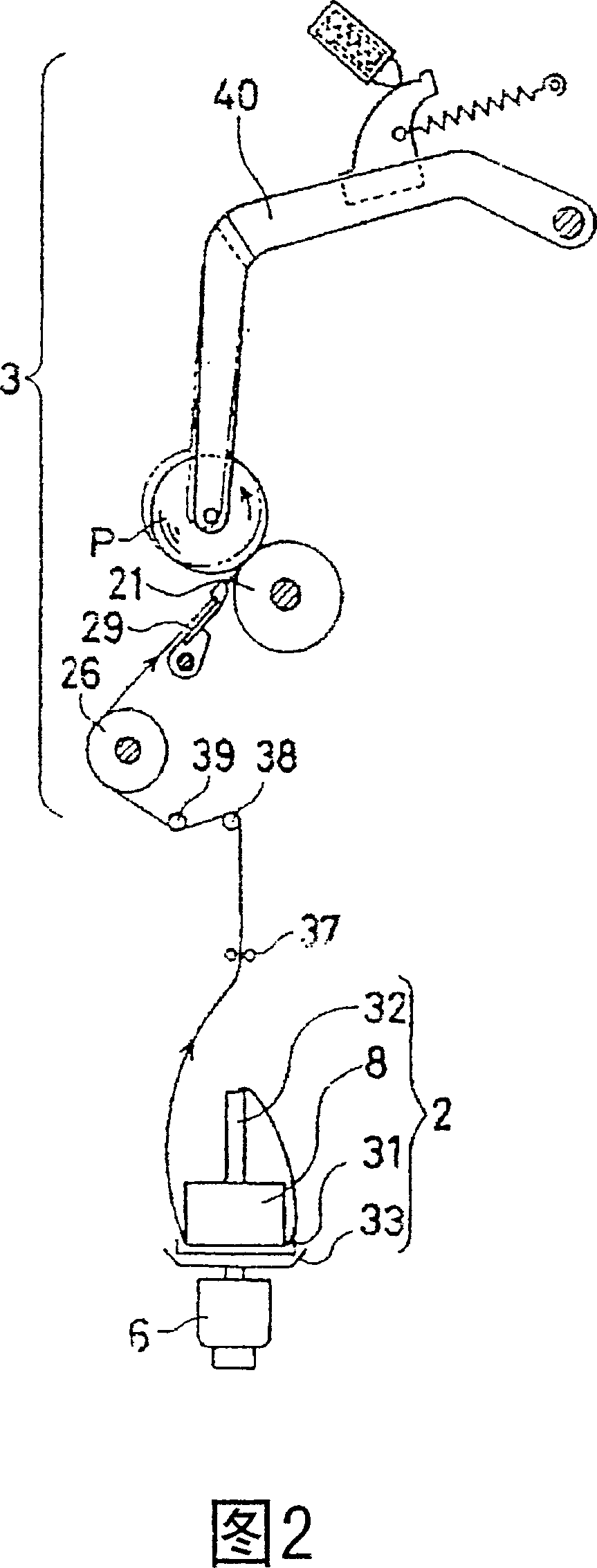

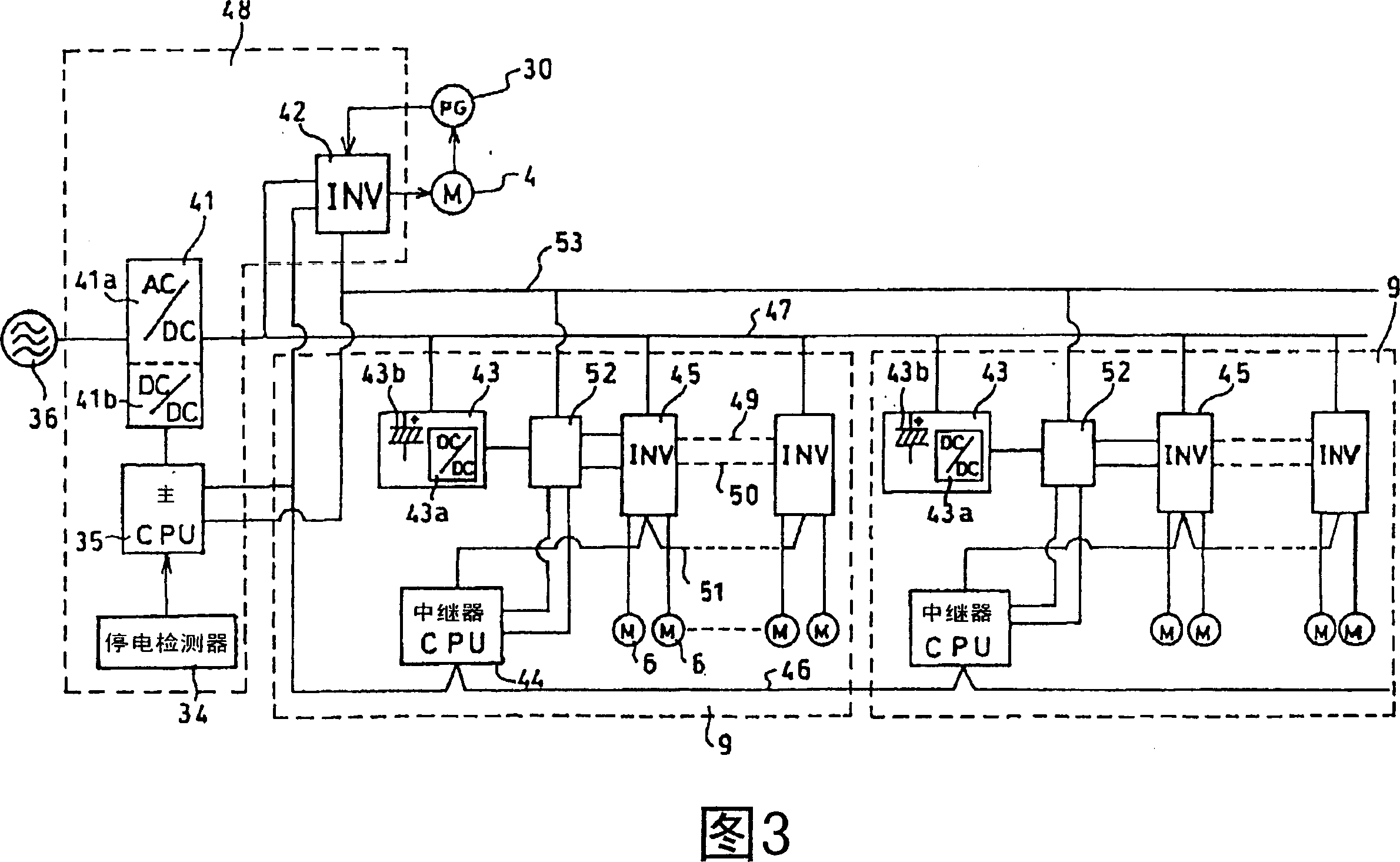

[0044] Next, a first embodiment of the present invention will be described with reference to FIGS. 1-4. The single-spindle-driven multi-twister 1 is configured by arranging yarn winding units U of 80 to 308 spindles in parallel, as shown in FIG. 1 . The one-spindle yarn winding unit U is provided with a spindle device 2 and a winding device 3 connected thereto above it, and winds a single yarn supply package 8 onto a take-up package P.

[0045] The above-mentioned spindle device 2 is provided with a silk feeding package 8, a stationary disc 31, a tensioning device 32, a rotating disk 33 and a spindle drive motor 6, which twists the yarn Y by the spindle drive motor 6. A DC brushless motor BLM is used as the spindle drive motor 6, and a rotary disk 33 is provided on its output shaft. And on the rotary disc 33 is provided with a stationary disc 31, on which a silk feeding package 8 can be placed. A tensioning device 32 is also arranged on the top of the silk feeding package 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com