Spindle pivot drafting device for spinning frame

A technology of drafting device and spinning frame, which is applied in the field of spinning frame spindle tip drafting device, which can solve the problems of reducing the speed of output and yarn feeding, reducing the twist of yarn, and being easy to be drawn into details, etc., so as to improve quality, Increased speed, extended draft range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

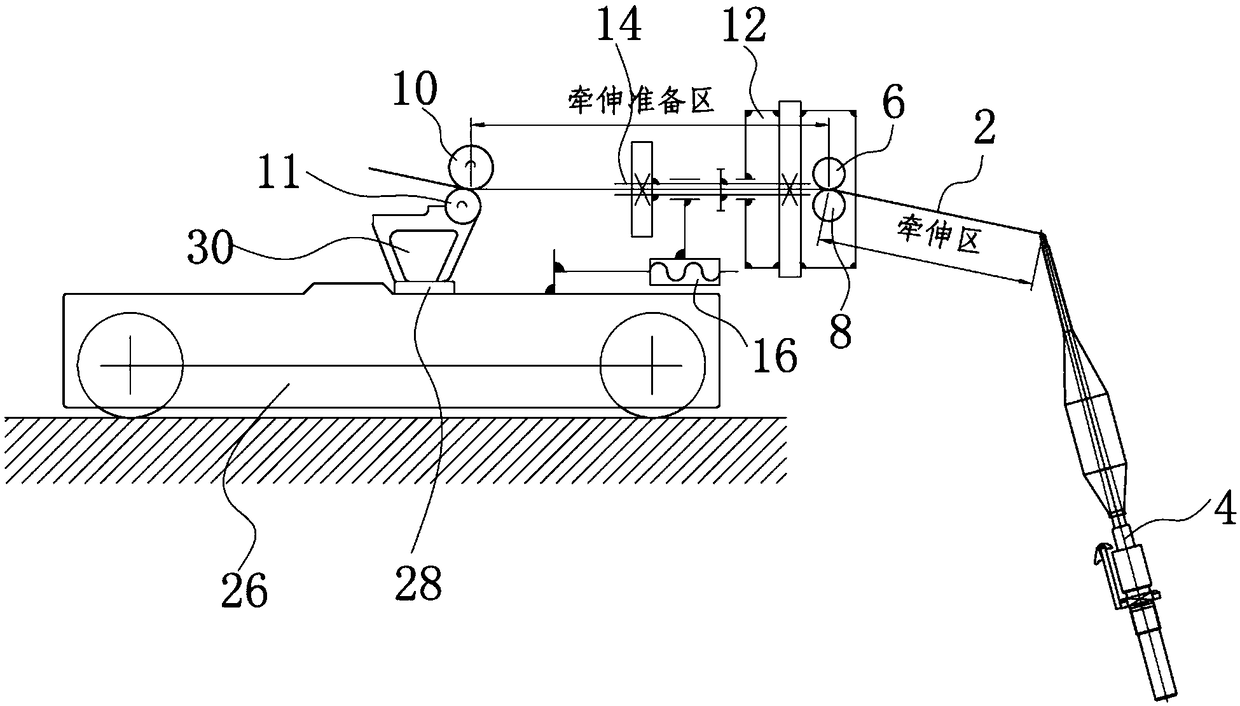

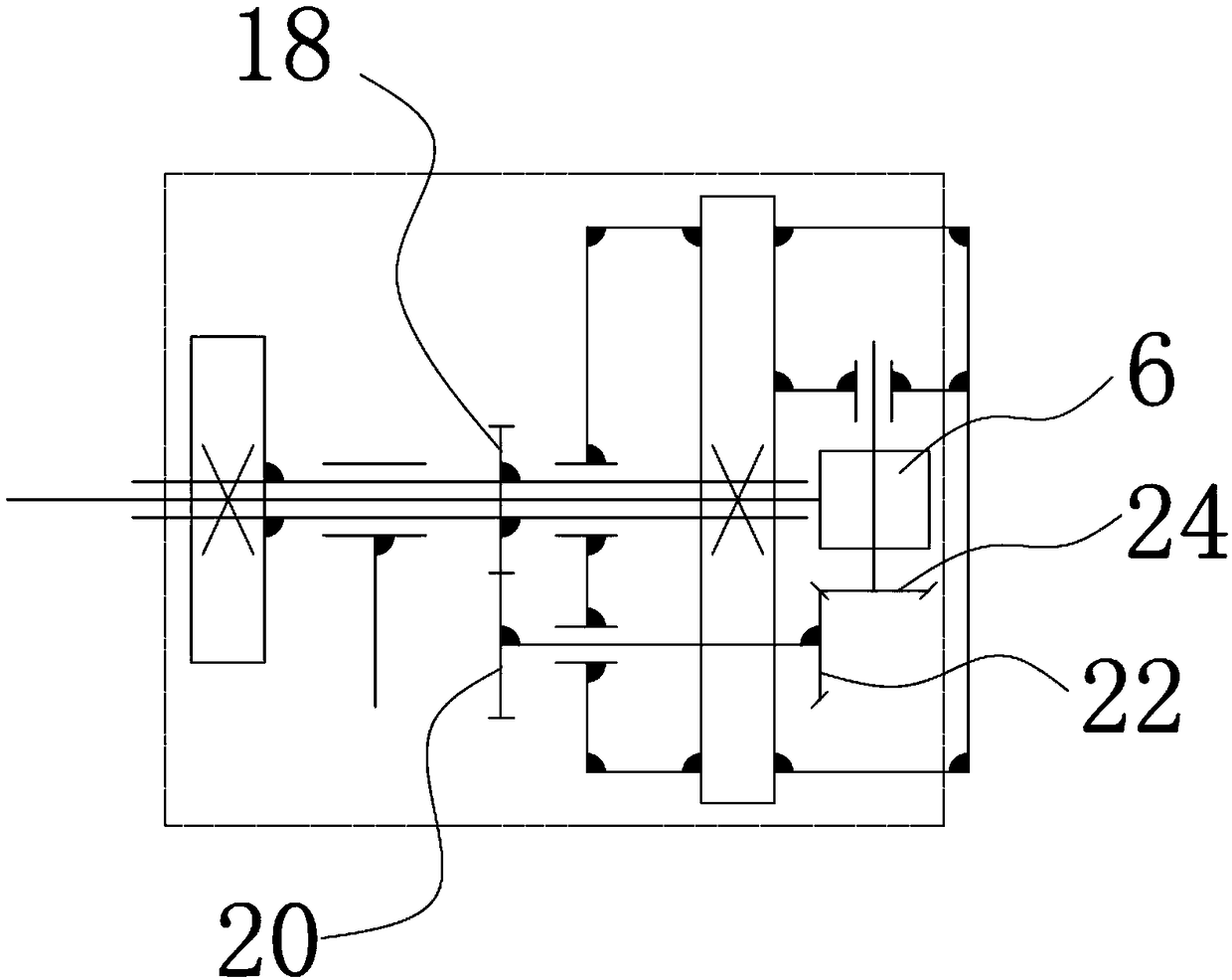

[0025] Such as Figure 2-3 As shown, this embodiment discloses a spindle tip drafting device of a spinning frame, which is used to draft the yarn 2 and send it to the spindle 4, which includes a drafting preparation area and a drafting area arranged in sequence along the yarn moving direction; A first roller 6 and a second roller 8 are arranged between the drafting preparation area and the drafting area, the first roller 6 and the second roller 8 are paired, and the first roller 6 rotates under the drive of the power source;

[0026] The third roller 10, the fourth roller 11 and the rotating cylinder 12 are arranged in the above-mentioned drafting preparation area, and the above-mentioned third roller 10 and the fourth roller 11 are set in pairs; the above-mentioned rotating cylinder 12 rotates under the drive of the power source, and the above-mentioned rotating cylinder 12 cooperates with the first roller 6, the second roller 8, the third roller 10, and the fourth roller 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com