Method and device for producing nonwoven web made of fibers

A non-woven fabric and fiber technology, applied in felting equipment, non-woven fabrics, fiber treatment, etc., can solve problems such as the solution is susceptible to interference, cannot produce non-woven fabrics, and cannot be calendered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

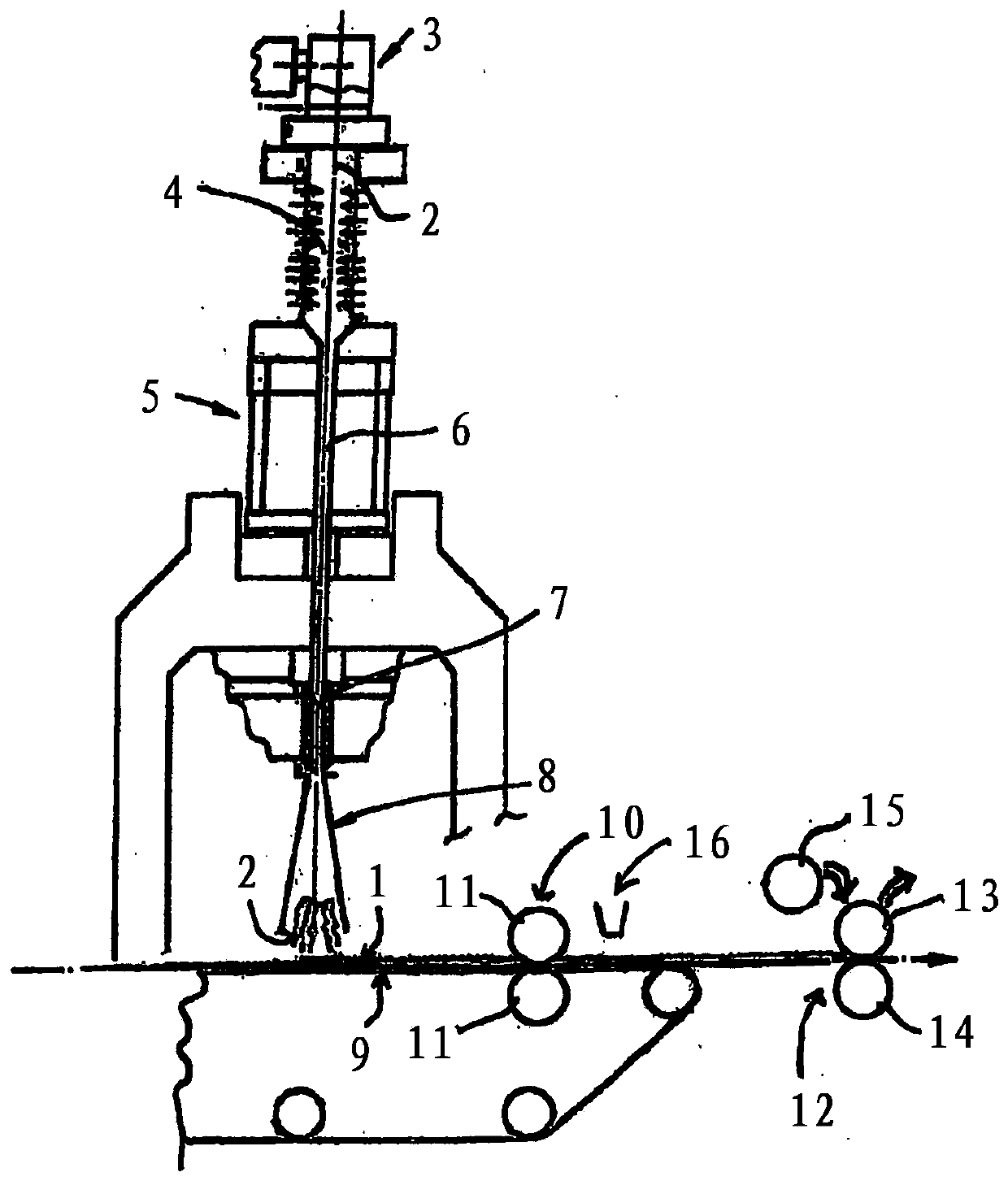

[0035] in the attached figure 1 A device for producing a spunbond nonwoven web 1 made of continuous filaments 2, preferably and in this embodiment filaments made of thermoplastics, is shown in 2. Preferably and in this exemplary embodiment, the filaments 2 are spun by means of a spinning device or spinneret 3 and then cooled in a cooling device 4 . A stretching device 5 for stretching the filament 2 is connected to the cooling device 4 in the flow direction of the filament 2 . Preferably and in this embodiment, the stretching device 5 has a central channel 6 constricting in the direction of flow of the filament 2 and a stretching channel 7 connected thereto. Preferably and in this exemplary embodiment, the assembly consisting of the cooling device 4 and the stretching device 5 is configured as a closed system. In this closed system, no further air supply takes place than the supply of cooling air or process air in the cooling device 4 . According to a preferred embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com