Method and device for winding and forming rough yarn after bobbiner is full of yarn

A technology of roving frame and roving, which is applied in the direction of spinning machine, spinning machine with continuous winding, spinning machine with intermittent winding, etc. It can solve the problem of yarn falling off and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

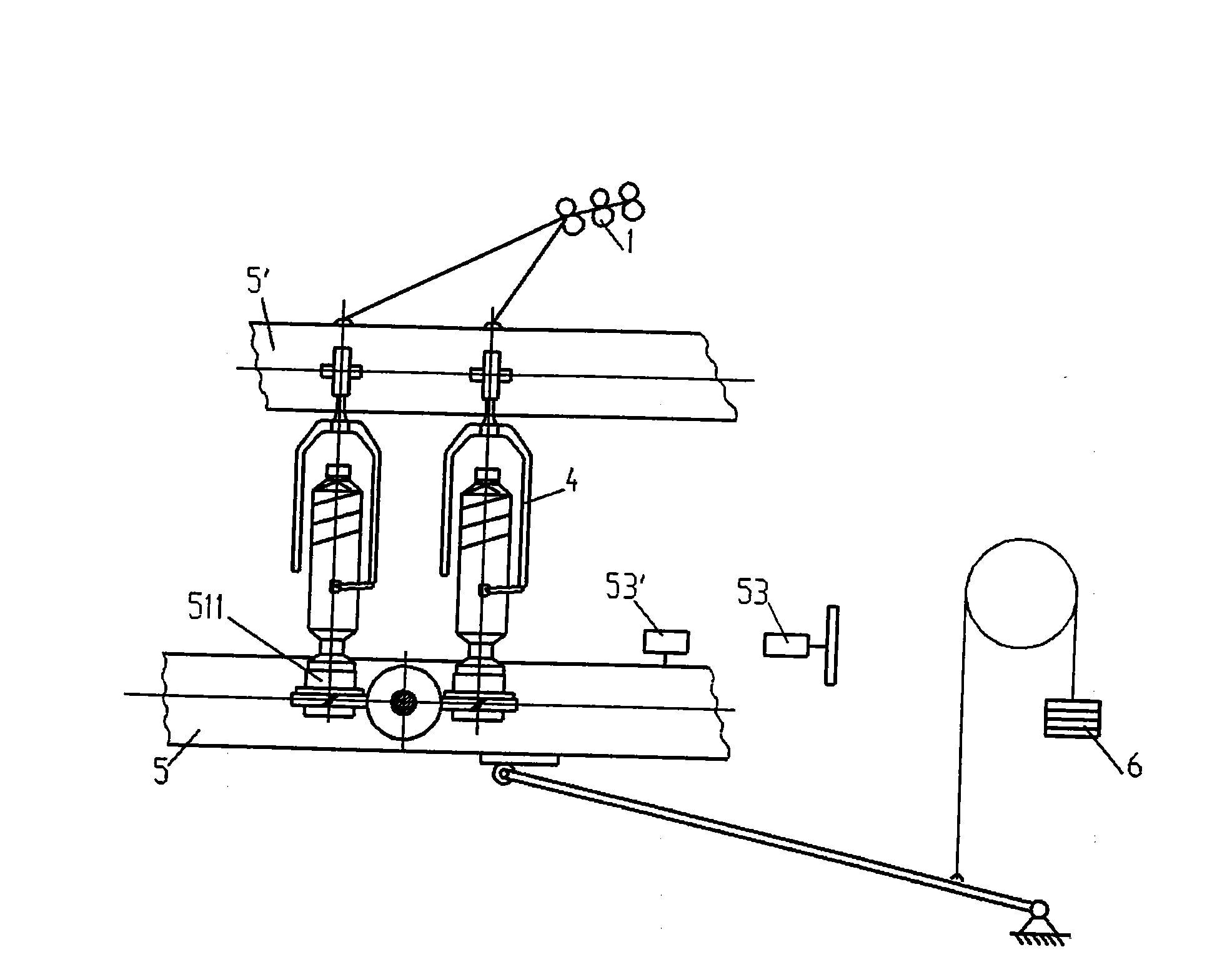

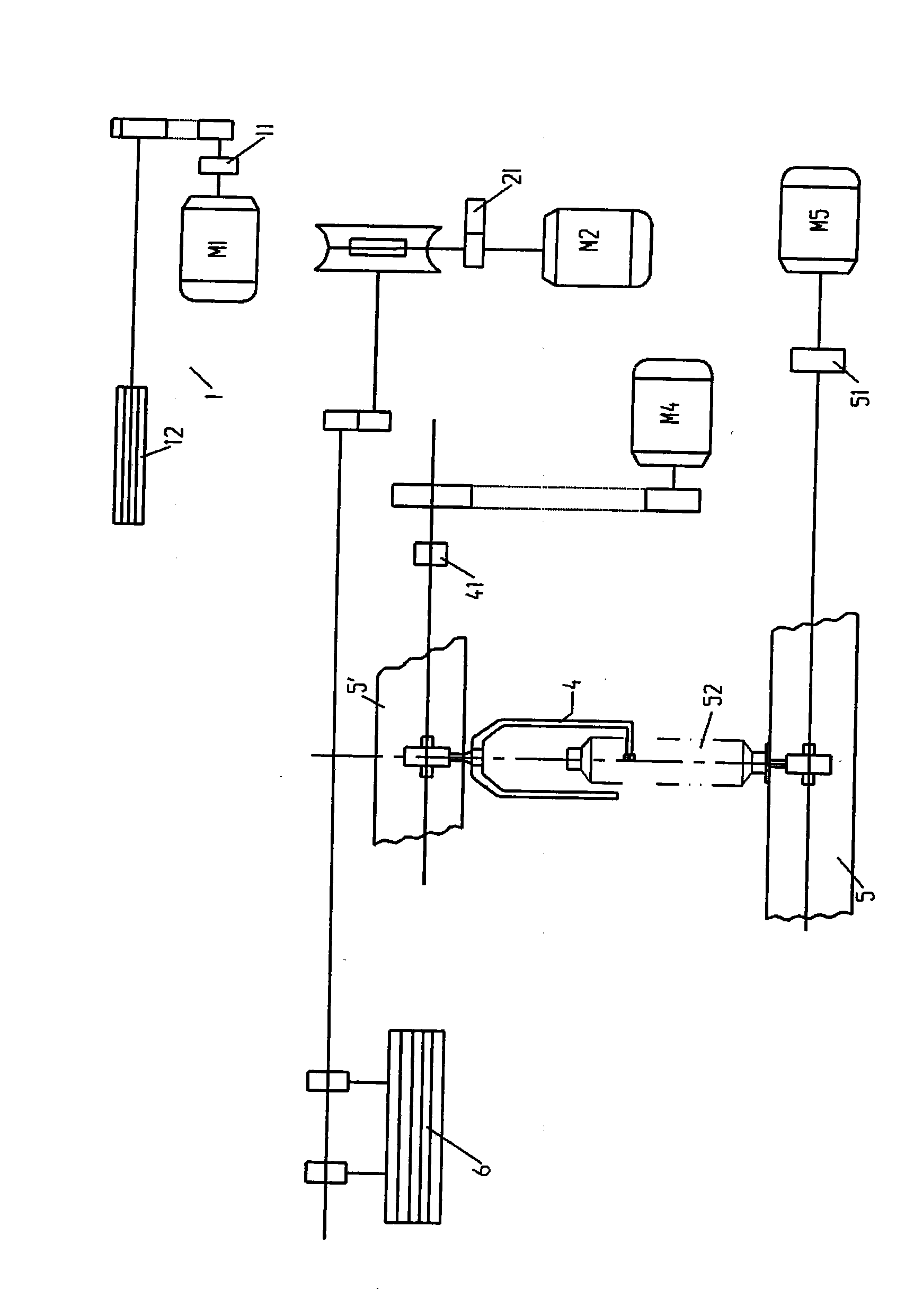

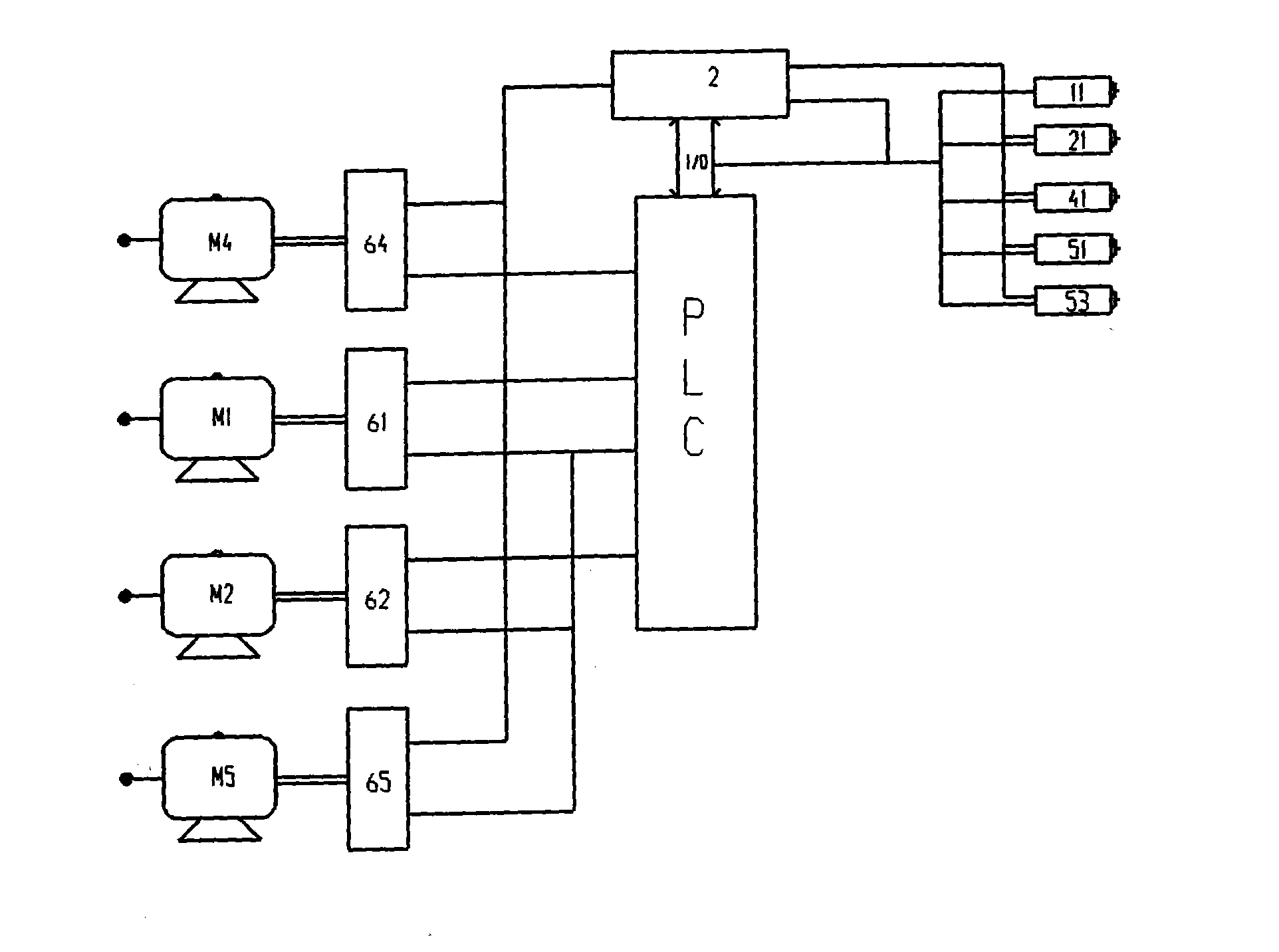

[0033] refer to figure 1 As shown, the device for winding and shaping the roving after the roving frame is full of yarn in the present invention is arranged on the roving frame, including a main control unit 2, a programmable logic controller (PLC), and a plurality of variable speed control devices 61, 62, 64 and 65, the flyer 4, the lower dragon rib 5 and a plurality of detection devices 11, 21, 41, 51 and 53; the lower dragon rib 5 is provided with a bobbin rotating body 511, which is equipped with the aforementioned spindle The bobbin 52 that the wing 4 is matched with;

[0034] The draft detection unit 1 is composed of a draft device 12 driven by a motor M1 and a detection device 11 connected to the draft device 12; the detection device 11 is connected to the main control unit 2 and sends a speed signal;

[0035] The variable speed control devices 61, 62, 64, 65 drive the motors M1, M2, M4, M5 respectively, and are connected with the main control unit 2 and a programmabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com