Linkage device for realizing synchronous and same-phase running of all flyers or bobbins of roving frame

A linkage device and roving frame technology, applied in the field of machinery, can solve problems such as the inability to ensure the synchronous operation of the flyer or the bobbin in the same phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

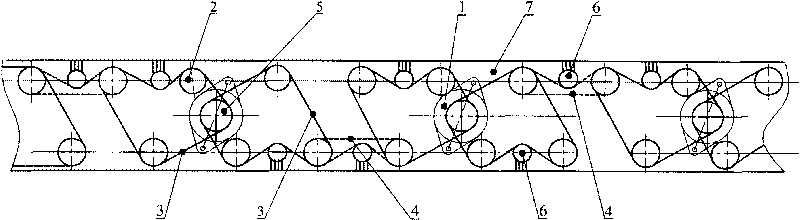

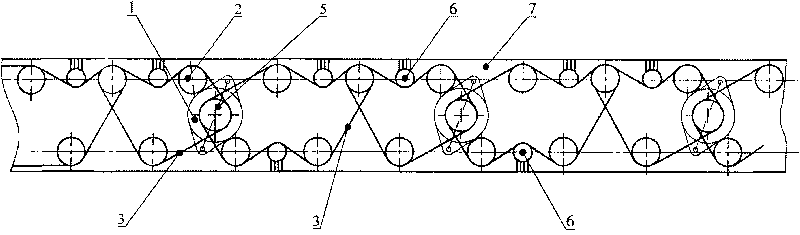

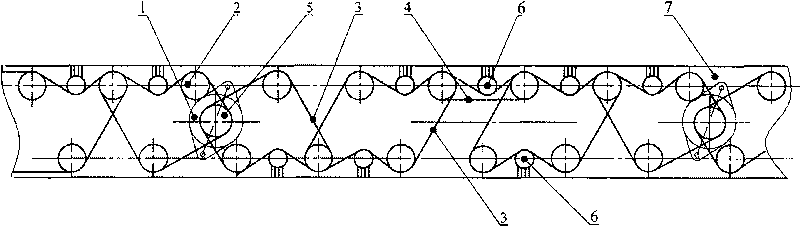

[0019] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, a linkage device of the present invention that enables all flyers or bobbins of a roving frame to operate synchronously and in phase is composed of more than two transmission groups, wherein any one of the transmission groups is composed of 2 to 48 A synchronous pulley 2, a second synchronous pulley 5, a synchronous belt 3 and a motor 1 are formed, any one of the first synchronous pulley 2 is arranged on the dragon rib 7, and any first synchronous pulley 2 is Connected by the synchronous belt 3, any one of the motors 1 is connected to the second synchronous pulley 5, and any synchronous pulley 2 is connected to the synchronous pulley 5 through the synchronous belt 3.

[0020] like figure 2 , Figure 4 , Figure 5 , there is a synchronous belt 2 in any transmission group connected to a synchronous pulley 2 in an adjacent transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com