A mechanism for a filling machine with synchronous bottle feeding and positioning functions

A filling machine and bottle feeding technology, which is applied in liquid bottling, packaging, bottle filling, etc., can solve problems such as inconvenient adjustment, time-consuming, easy to fall bottles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

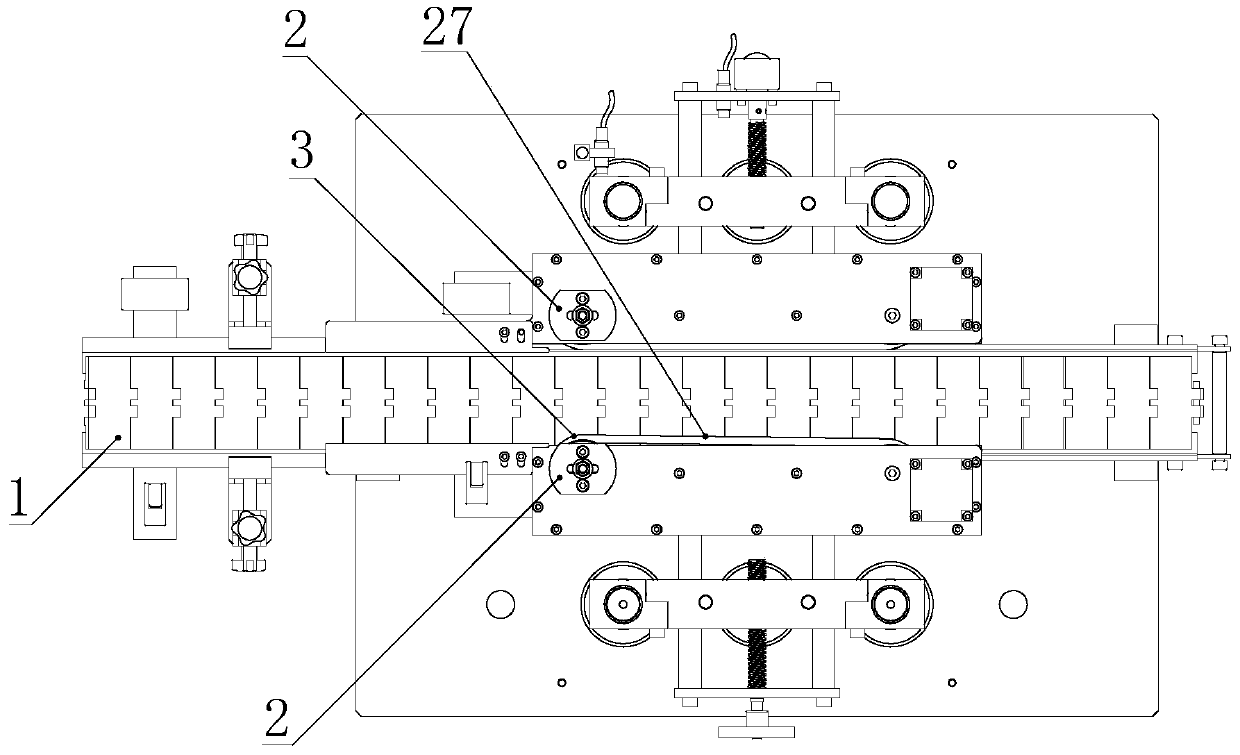

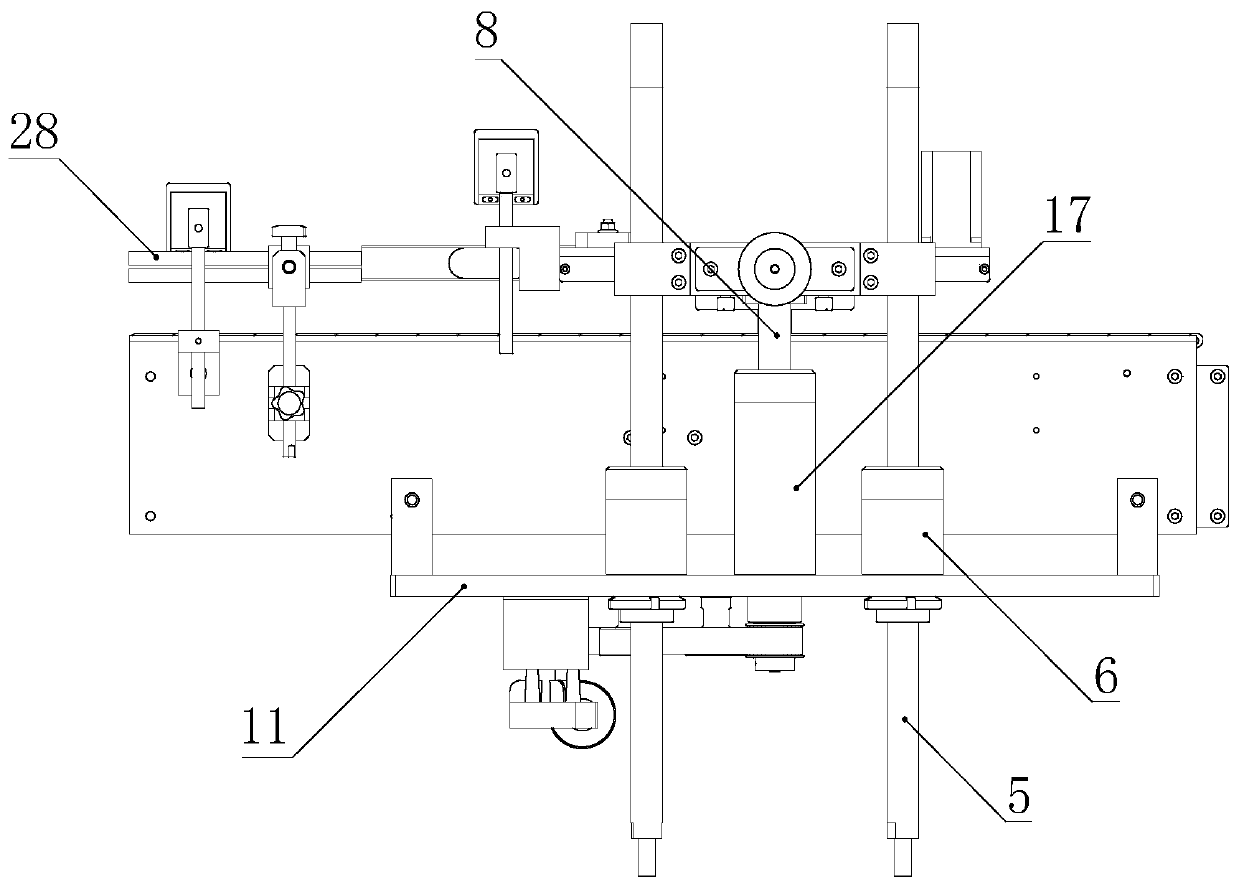

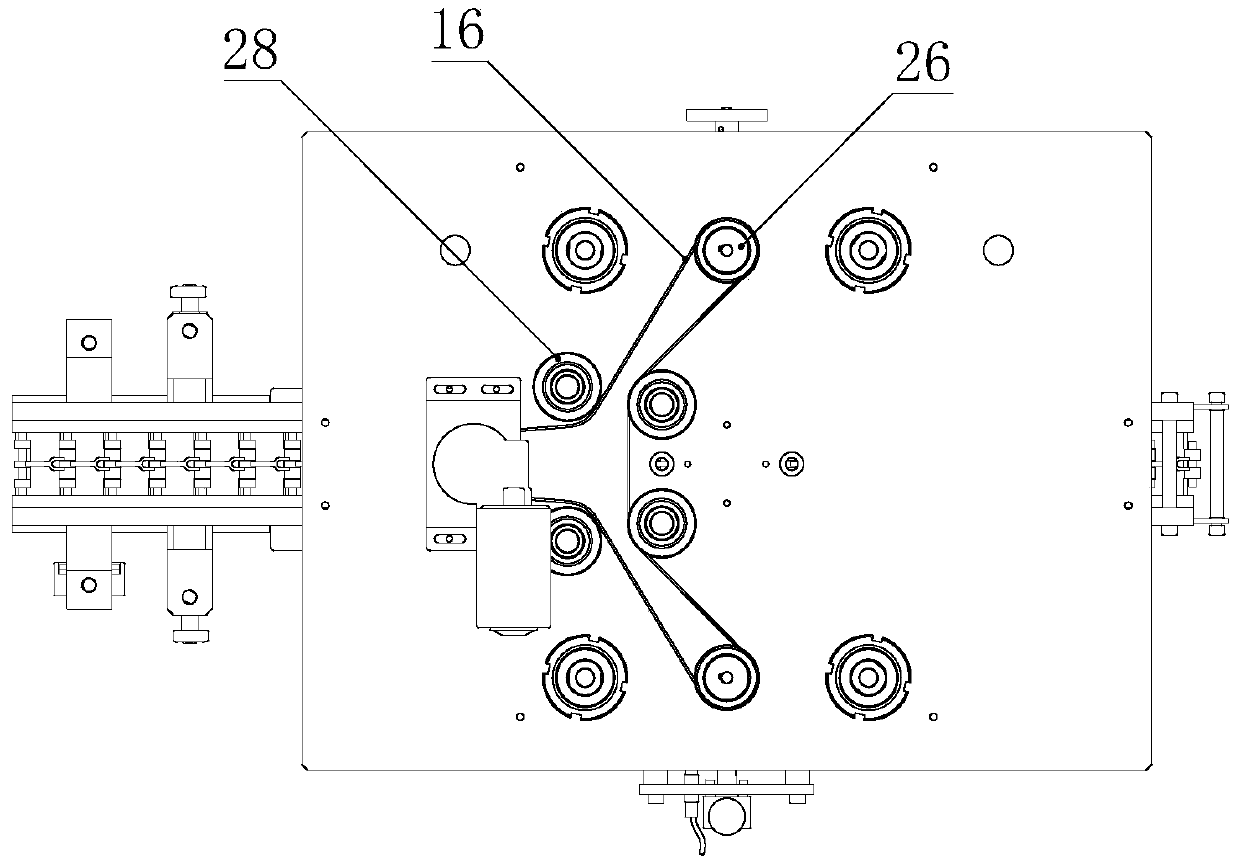

[0028] see Figures 1 to 10 , a mechanism for a filling machine with synchronous bottle feeding and positioning functions, including a timing belt 1 and a number of two belt-type bottle-stopping mechanisms 2, the number of which is two belt-type bottle-stopping mechanisms 2 on the timing belt 1 The two sides of the belt are arranged symmetrically with the synchronous belt 1 as the center. The belt-type bottle blocking mechanism 2 includes the bottle blocking synchronous belt 3. The working surface of the bottle blocking synchronous belt 3 is perpendicular to the working surface of the synchronous belt 1. The cross section is arc-shaped.

[0029] A mechanism for a filling machine with synchronous bottle feeding and positioning functions, which also includes a synchronous belt clamp seat 4, a lifting shaft 5, a sliding film 6 and a synchronous belt lifting assembly (not shown in the figure), and the synchronous belt 1 is set at the number There are 4 synchronous belt holders 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com