A vacuum packaging inkjet coding line

A vacuum packaging and material sorting technology, applied in the field of material sorting lines, can solve the problems of low work efficiency and high labor costs, and achieve the effects of reducing production costs, shortening processing time, and extending shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further specifically described below in conjunction with the accompanying drawings and through specific embodiments.

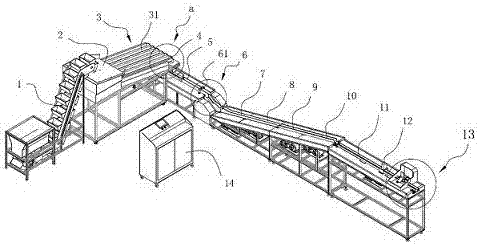

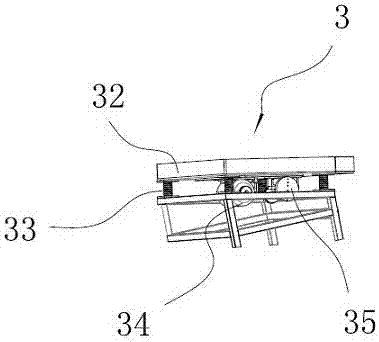

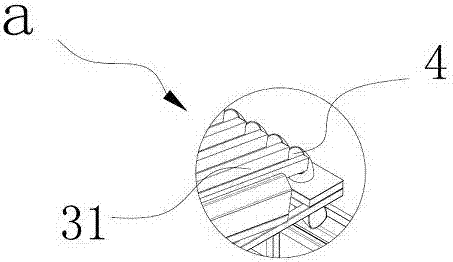

[0019] like figure 1 As shown, a vacuum packaging inkjet coding line includes an electric control cabinet 14 for providing power to the material line, and a quantitative hoist 1 for conveying and lifting bagged materials, which is arranged under the quantitative hoist 1 The transition inclined platform 2 for receiving bagged materials is connected with the outlet of the transition inclined platform 2 and the vibrating material arrangement device 3 for vibrating and scattering the bagged materials. One end of the outlet of the vibration material arrangement device 3 is connected to multiple A material turns to the sliding cylinder 4, is provided with the material sending out belt 5 below the material turning to sliding cylinder 4, and the end of the material sending out belt 5 away from the material turning to sliding cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com