Power delivery device applied to annular processing line

A processing line and power technology, applied in the field of mechanical processing, can solve problems such as difficult to arrange straight lines, and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

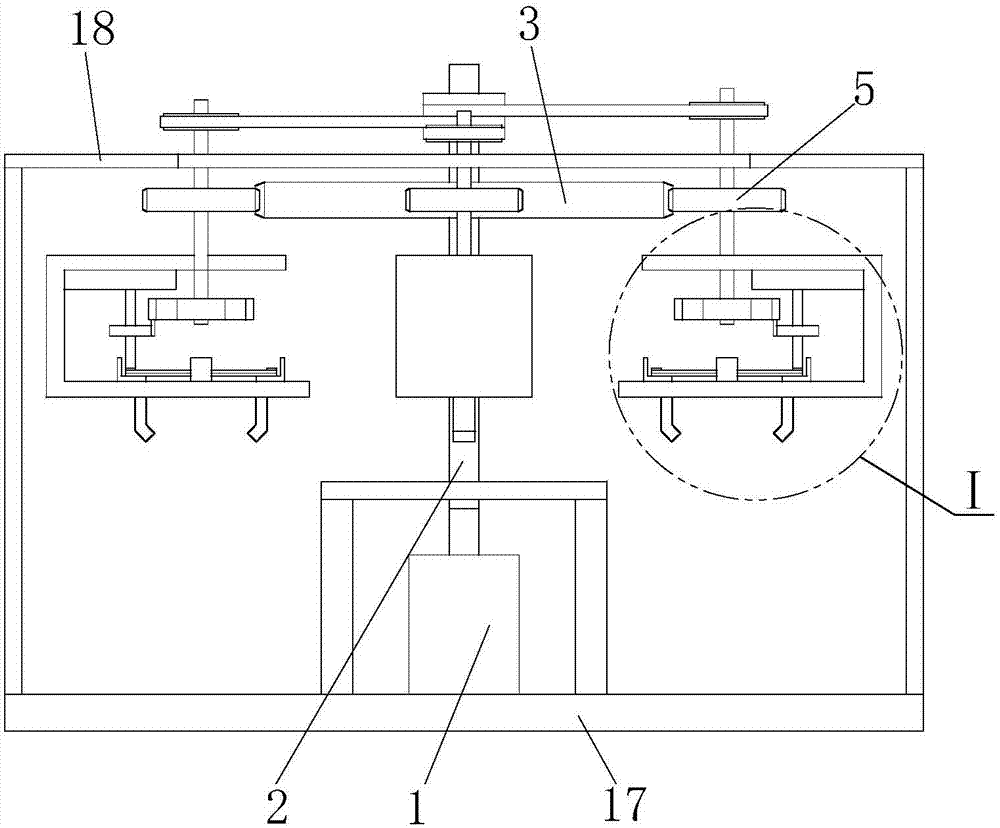

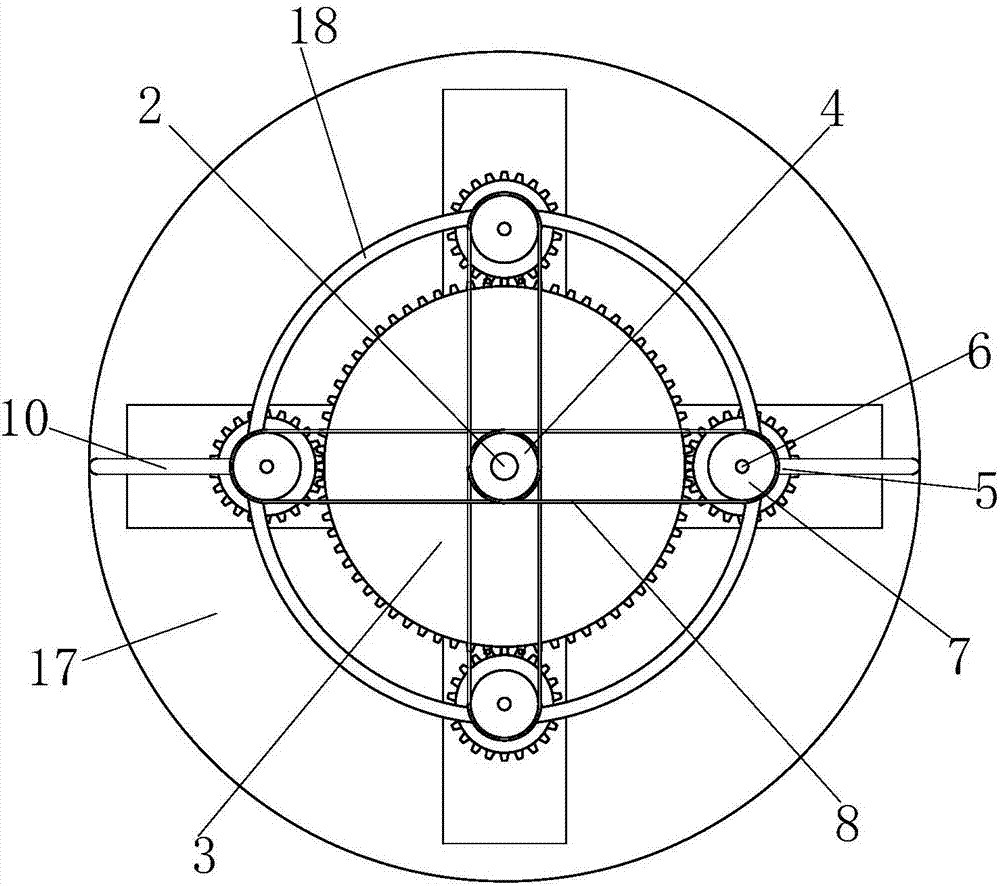

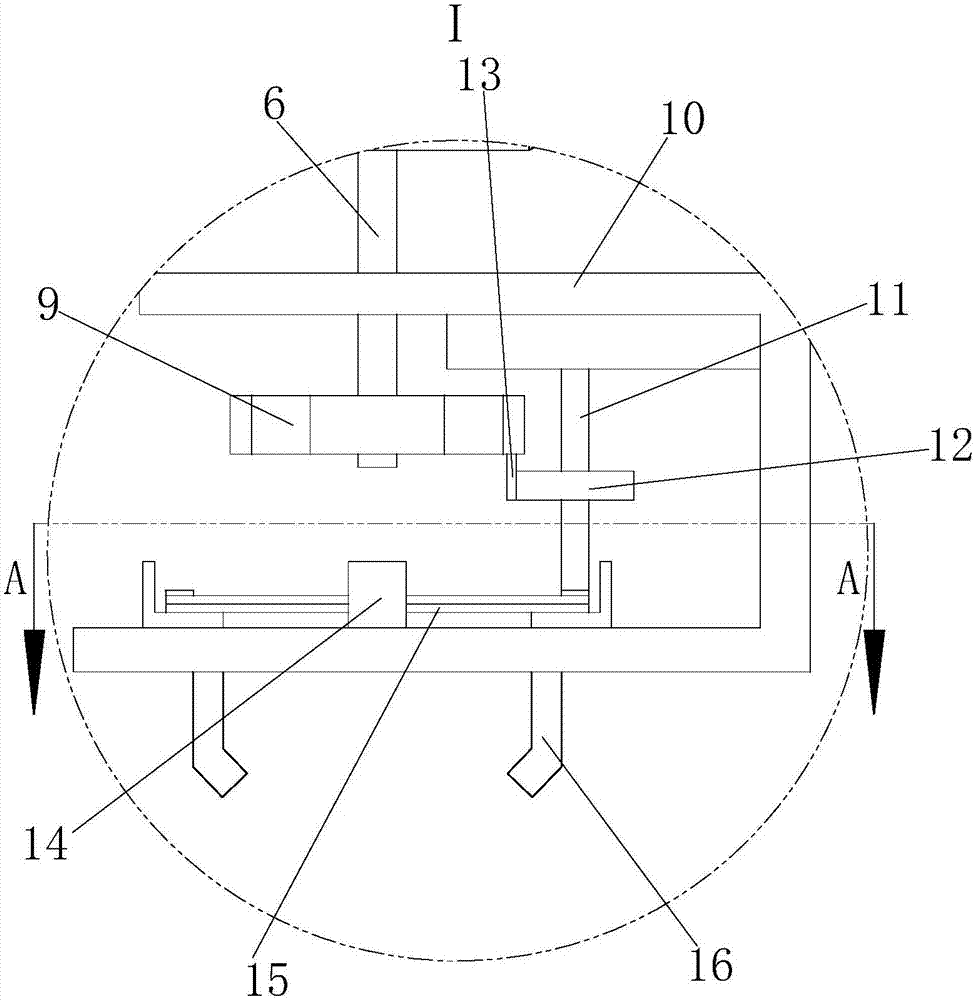

[0022] Such as Figure 1 to Figure 5 As shown, a power distribution device applied to a circular processing line includes a base plate 17 and a motor 1 mounted on the base plate 17. The motor 1 is connected to a central shaft 2, and the upper ends of the central shaft 2 are respectively connected by bearings. 1. The key connection mode is correspondingly connected with a bull gear 3 and a center pulley 4, and four pinions 5 meshing with the bull gear 3 are evenly distributed around the bull gear 3, and each pinion 5 is connected with a sub-shaft 6 , each sub-shaft 6 is connected with sub-belt pulley 7, between each sub-pulley pulley 7 and the center pulley 4, there is a belt 8 connecting the two transmissions. The base plate 17 is provided with a sub-frame 18 for slidingly installing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com