Transmissive belt damage detecting device and method

A damage detection and penetrating technology, which is applied in the direction of conveyor control devices, transportation and packaging, conveyors, etc., can solve problems such as inability to achieve real-time detection, high degree of equipment damage, and large-area belt damage, so as to avoid secondary damage Effects of long-distance belt damage, reduced maintenance, and reduced replacement and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

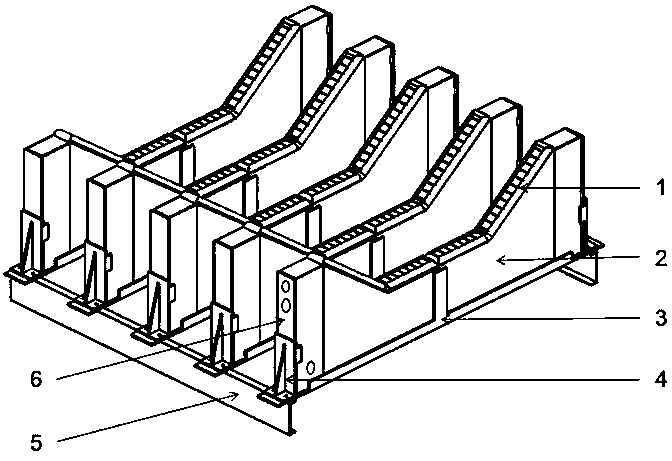

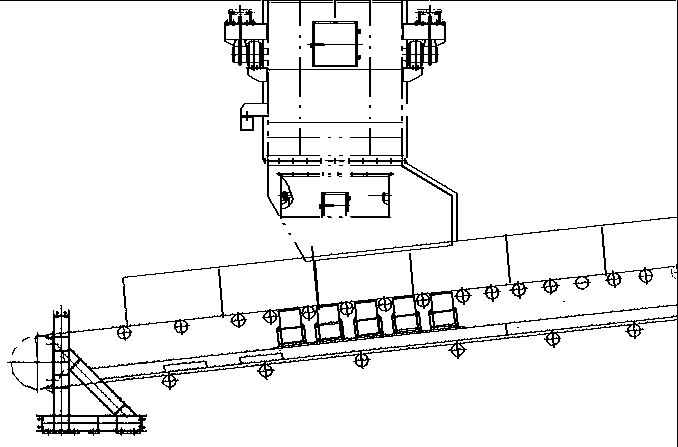

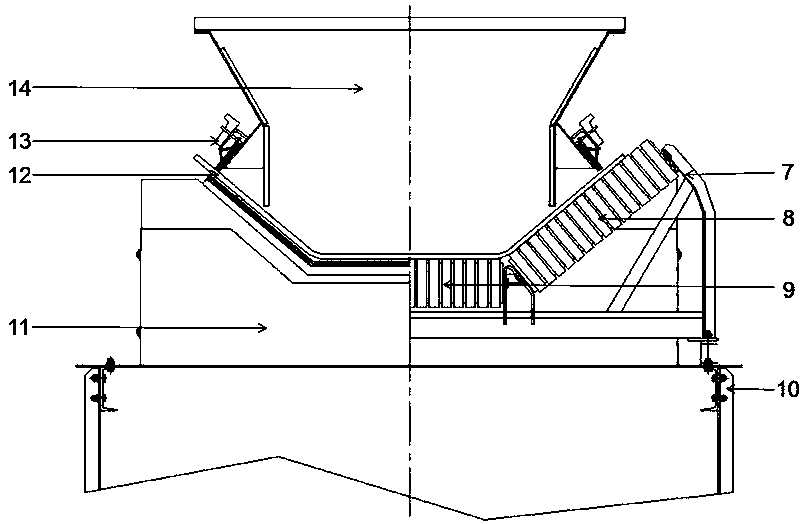

[0031]A penetrating belt damage detection device, characterized in that it includes a penetrating belt damage detection module 11 and a belt conveyor, the penetrating belt damage detection module 11 is installed on the belt conveyor, and the penetrating belt damage detection module 11 includes an airbag 1. Airbag cover 2, airbag cover support frame 3, airbag cover side baffles 4, airbag cover control panel 6; belt conveyor includes buffer idler bracket 7, belt conveyor steel structure 5, first buffer idler 8, second Buffer idlers 9, belt conveyor steel structure columns 10, conveyor belts 12, material guide trough retaining skin device 13, belt conveyor guide trough 14; the penetrating belt damage detection device has at least two sets of penetrating belt damage detection devices. Detection module 11; the penetrating belt damage detection module 11 is installed directly below the conveyor belt 12 of the belt conveyor guide groove 14, in order to prevent the conveyor belt 12 fro...

Embodiment 2

[0043] The device structure embodiment 1 of the present embodiment is the same except that it also has the following structure for realizing the detection method:

[0044] The detection device has a temperature detector and a background control host, and transmits the detection result of the temperature detector to the control host, the airbag has an inflation port, and the inflation port has the functions of inflation and deflation; Temperature and pressure information, and construct temperature and pressure curves;

[0045] The control host adjusts the airbag to work in a safe range according to the temperature and pressure curve of the airbag. When the ambient temperature rises or the working time prolongs to cause the air temperature in the airbag to rise, the control host controls the airbag to exhaust to reduce the air pressure to prevent excessive air temperature. causing the airbag to rupture.

[0046] The device also has a self-inspection airbag, the self-inspection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com