Flat bar system

A slat and cover plate technology, applied in the field of cover slat system, can solve problems such as quality degradation and tension, and achieve the effect of simplifying operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

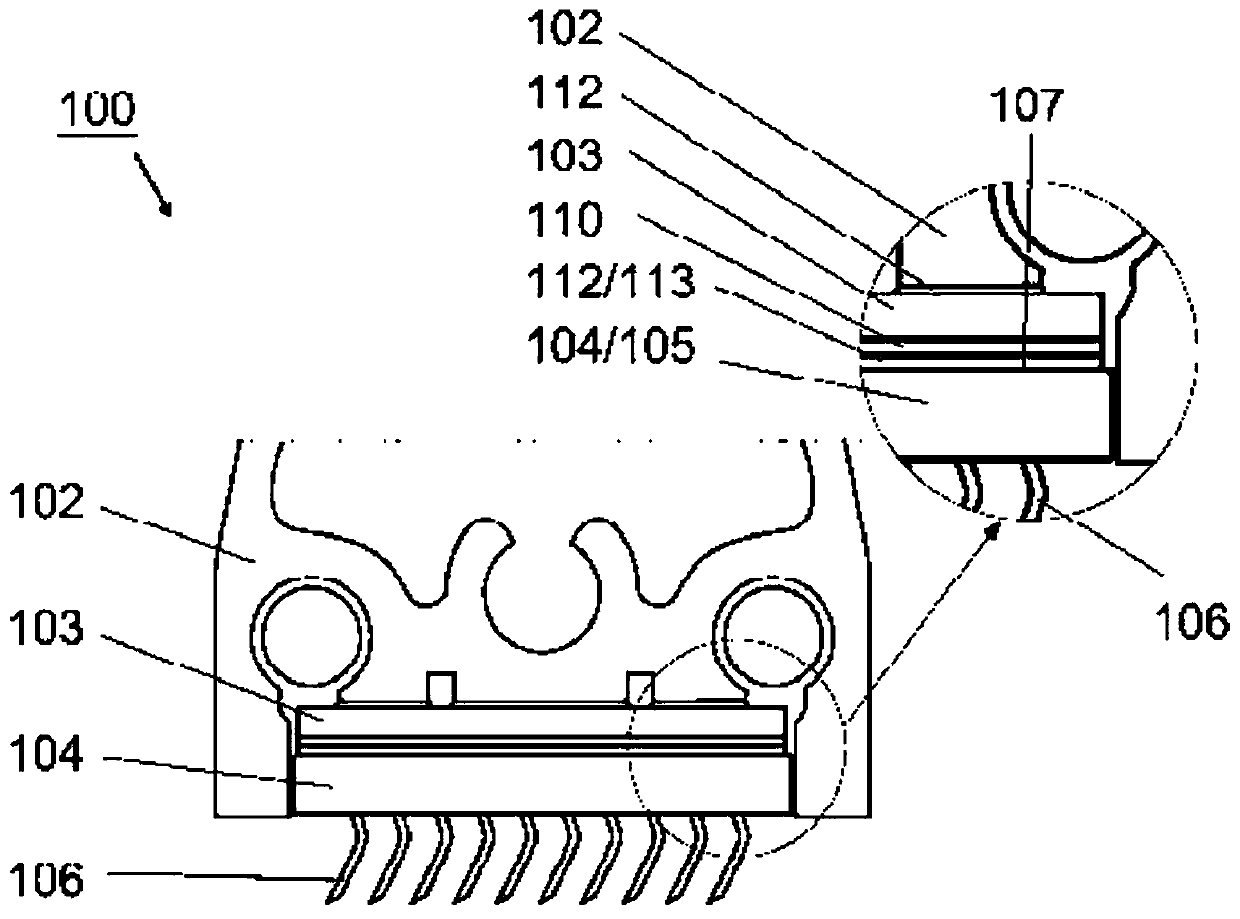

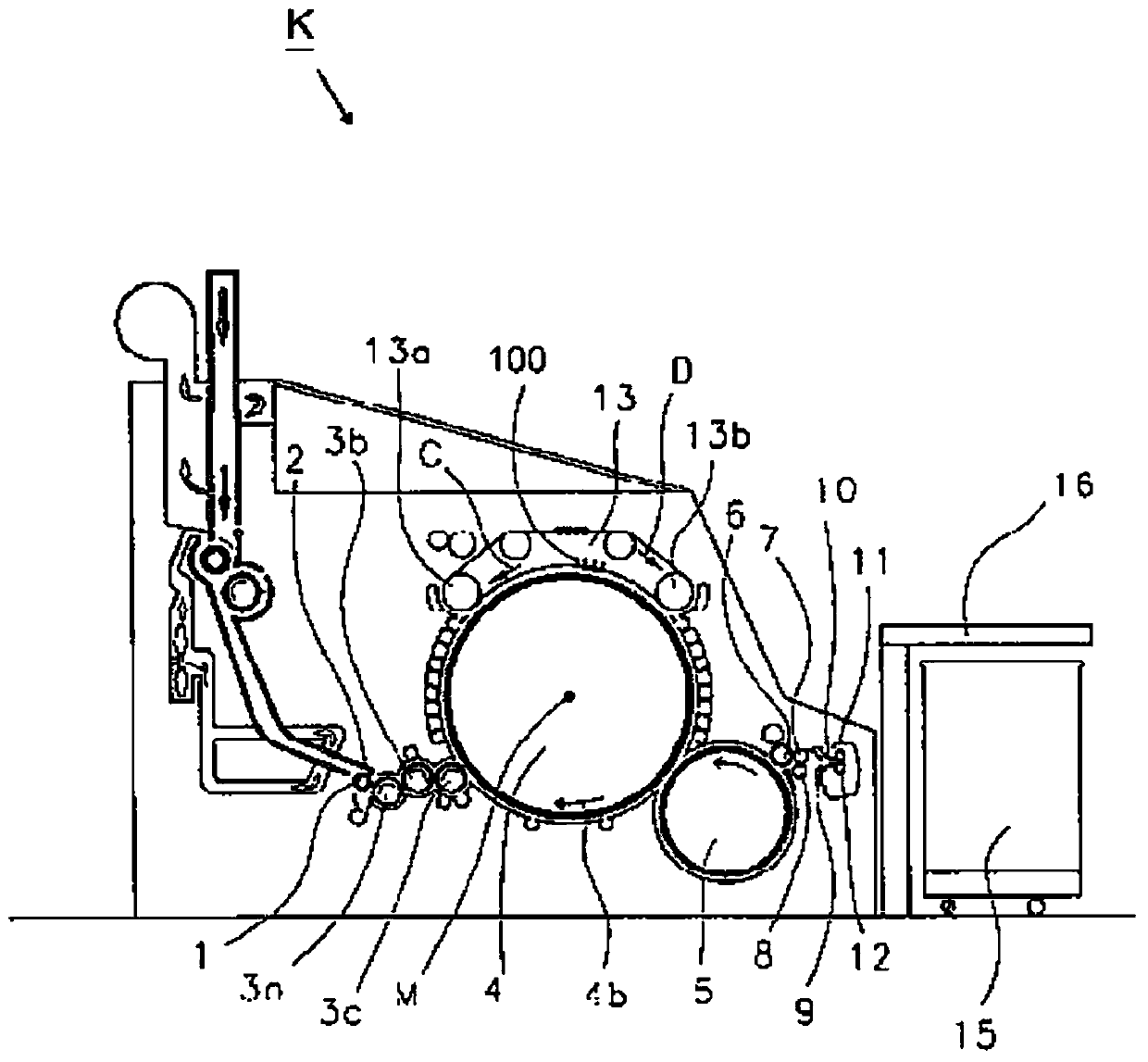

[0025] Refer below Figure 1 to Figure 8 A preferred embodiment of the flat strip system 100 according to the invention, which is intended to be used on a carding machine for cotton, chemical fibers or the like, will be explained. Identical features in the figures are each provided with the same reference numerals. It should be understood here that the drawings are only shown simplified and in particular not to scale.

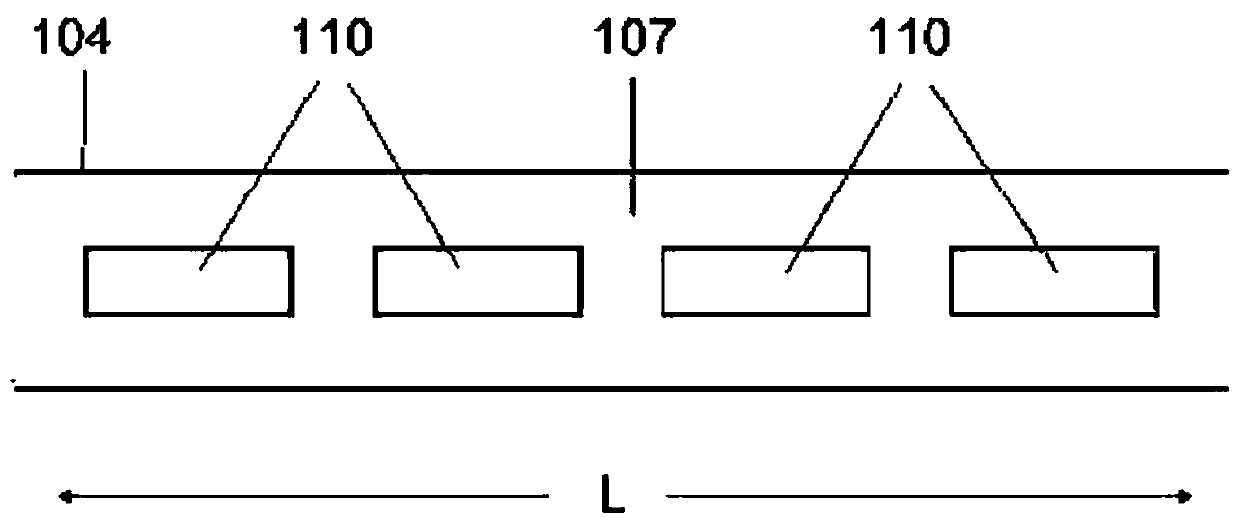

[0026] figure 1 The cover strip system 100 is shown in cross section. The cover strip system 100 comprises an elongated cover strip 102, which is preferably produced from aluminum. A magnetic element 103 is fastened to the cover strip 102 . On the flat strip 102 a clothing strip 104 with clothing points 106 is mounted adjacent to the magnetic element 103 , ie by using magnetic force, as will now be explained in detail.

[0027] In the enlarged area additionally shown figure 1 The area on the right of the cross-sectional view. It can thus be seen that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com