Variable-compression-ratio mechanism of engine and air distribution system matched with variable-compression-ratio mechanism

A compression ratio, engine technology, applied in the direction of engine cooling, engine components, engine control, etc., can solve the problems of increasing the difficulty of manufacturing parts and parts, increasing heat loss, and decreasing the thermal efficiency of gasoline engines, so as to improve the operation stability , easy to implement, and low implementation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

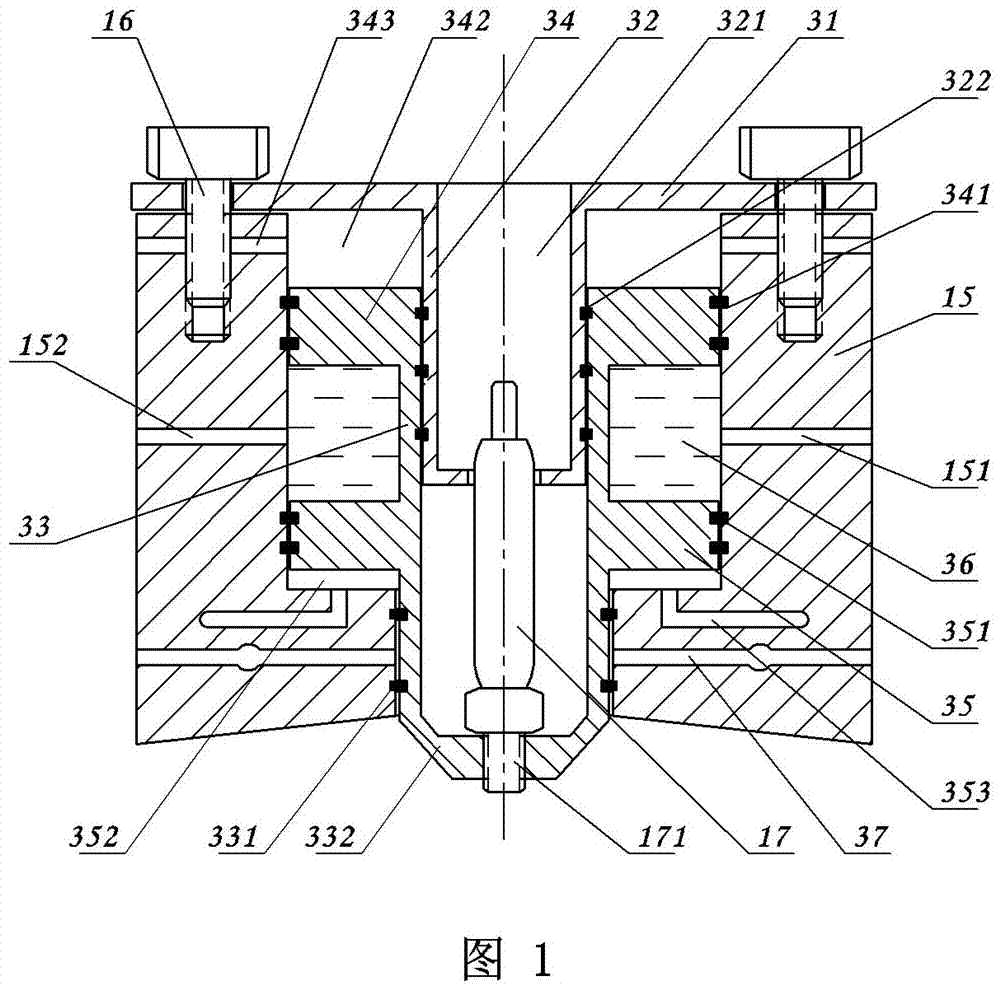

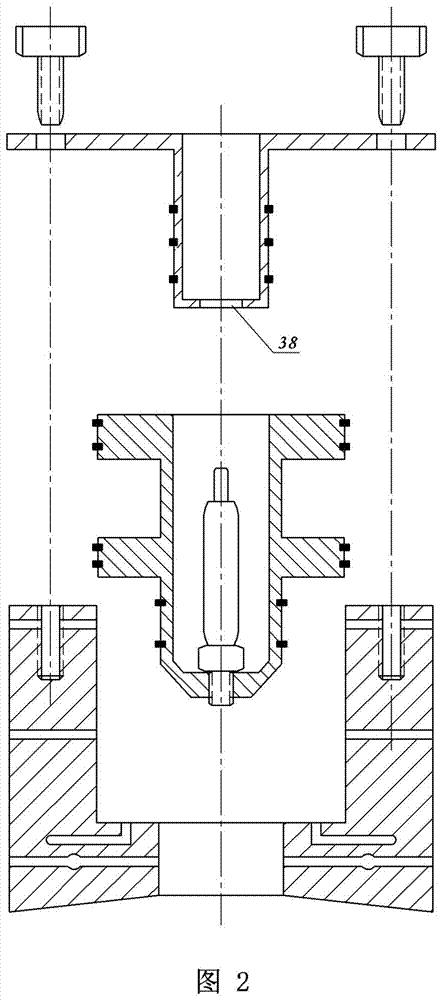

[0038] Embodiment 1: A kind of engine variable compression ratio mechanism, see figure 1 and figure 2 On the cylinder head, a circular hole communicating with the combustion chamber is opened at the installation position of the original spark plug at the top center of the combustion chamber as the auxiliary piston cylinder, and the auxiliary piston 33 is sealed and arranged in the auxiliary piston cylinder. After the circular hole is set and the auxiliary piston 33 is installed, the combustion chamber is still a complete closed space.

[0039] An auxiliary piston cover 31 is sealed and fixed on the top of the auxiliary piston cylinder to fix the auxiliary piston 33 . Wherein, a hollow structural cylinder is designed to extend downward at the center of the auxiliary piston cover 31, and a spark plug relief hole is arranged at the bottom thereof. The auxiliary piston 33 is also a hollow structure, and the hollow structure cylinder is sealed and sleeved on the inner surface of...

Embodiment 2

[0042] Embodiment 2: On the basis of Embodiment 1, the auxiliary piston 33 includes an upper annular piston and a lower annular piston and a cone-shaped hollow cylinder for installing a spark plug. The upper annular piston and the lower annular piston are respectively in sealing contact with the inner wall of the auxiliary piston cylinder. The conical hollow cylinder of the spark plug extends into the top of the combustion chamber, and its outer wall is in sealing contact with the inner surface of the channel communicating with the combustion chamber.

[0043] In this embodiment, the annular cavity formed between the upper annular piston and the lower annular piston is used as a cooling cavity, and the water inlet (or lubricating oil) port and the water (or lubricating oil) port communicating with the cooling cavity are respectively provided in the cylinder. Body cover.

[0044] The sliding mating surface that exists between the secondary piston 33 and the upper cover of the c...

Embodiment 3

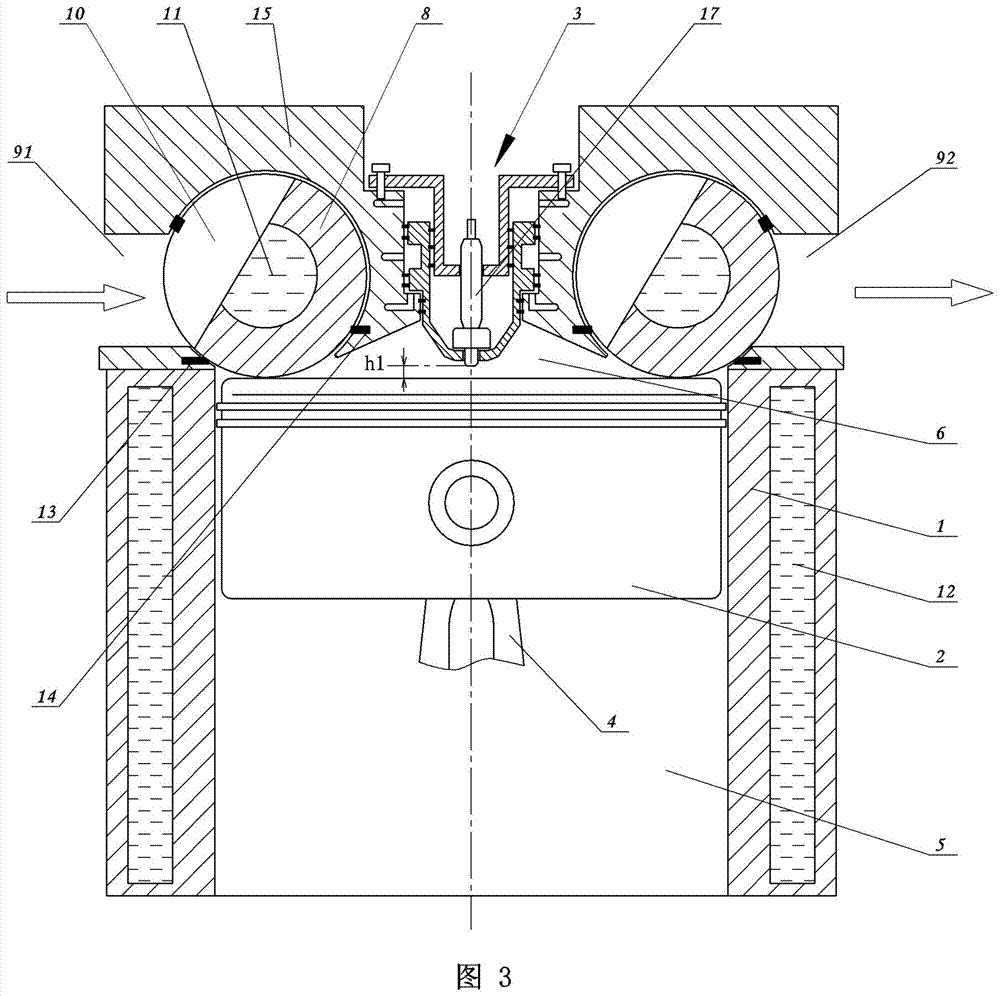

[0045] Embodiment 3: A gas distribution system containing a variable compression ratio mechanism, such as image 3 As shown, the intake valve and exhaust valve located at the top of the combustion chamber adopt the structure of intake valve shaft and exhaust valve shaft respectively. The combustion chamber is located at the top of the cylinder block 1, and the bottom of the cylinder block 1 is the piston 2, crankshaft and connecting rod 4 and other components.

[0046] For the specific structure of the valve shaft, see Figure 4 , on the intake valve shaft and the exhaust valve shaft, four (unlimited) protruding rotary valves whose outer diameter is larger than the outer diameter of the valve shaft are set. One side of the rotary valve is provided with a gap as an air flow channel 10, and the gap occupies a quarter of the circumference of the rotary valve.

[0047] The intake port 91 and the exhaust port 92 located at the top of the combustion chamber are respectively matche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com