Lightweight abrasion-resistant automobile gear and preparation method thereof

An automotive gear and lightweight technology, applied in the direction of belts/chains/gears, mechanical equipment, components with teeth, etc., can solve the problems of reducing the reliability of gears, shortening the service life of gears, and high production costs, and achieve excellent mechanics performance and usability, enhanced thermal conductivity, and overall lower mass effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

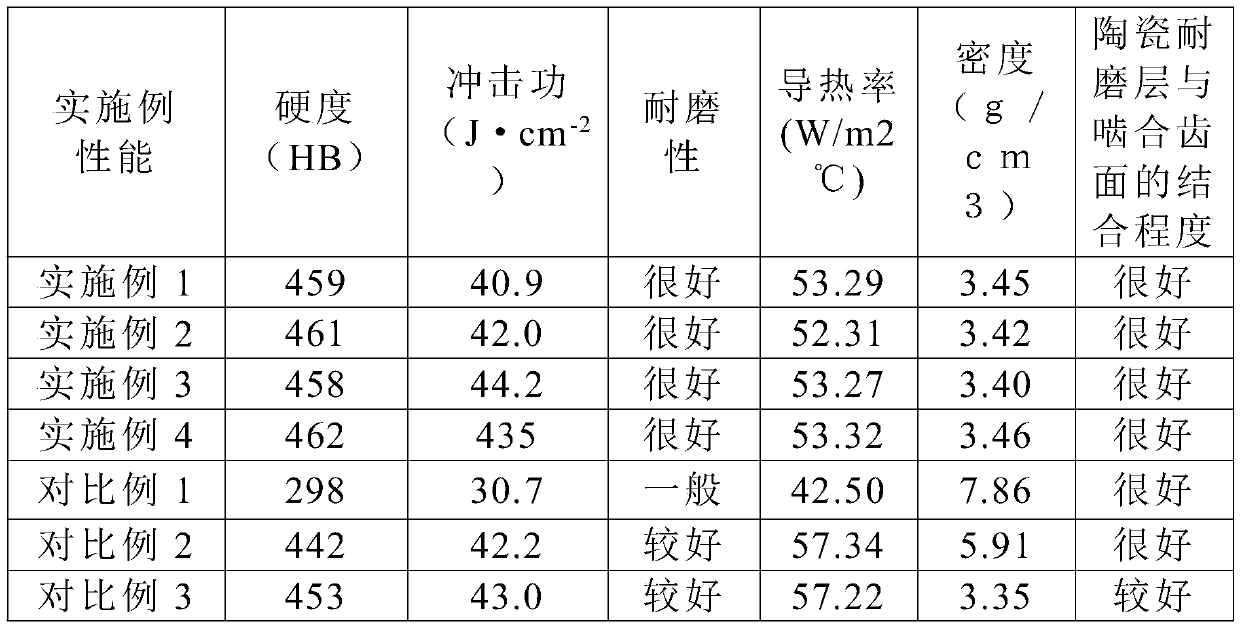

Examples

Embodiment 1

[0030] The automobile gear in this embodiment includes a core body and an outer layer arranged on the surface of the core body. The core body is made of porous alloy steel ceramic material, and the porous alloy steel ceramic material is made of alloy steel with a mass ratio of 100:50.1:0.6:9. powder, ceramic powder, porogen, and resin binder. The porosity of porous alloy steel ceramics is 60.4%, and the pore diameter is 22.0 μm. The outer layer is made of alloy steel ceramic materials. The alloy steel ceramic material is composed of a mass ratio of 100:50.1:7 alloy steel powder, ceramic powder, resin binder.

[0031] The automobile gear of the present embodiment is obtained by the following method:

[0032] Mix the alloy steel powder, ceramic powder, porogen, and resin binder with a mass ratio of 100:50.1:0.6:9, and press it into a core body under a pressure of 1000Mpa; the mass ratio is 100:50.1:7 Alloy steel powder, ceramic powder, and resin binder are mixed evenly, coated ...

Embodiment 2

[0036] The automobile gear in this embodiment includes a core body and an outer layer arranged on the surface of the core body. The core body is made of a porous alloy steel ceramic material, and the porous alloy steel ceramic material is made of alloy steel with a mass ratio of 100:80:0.8:10. powder, ceramic powder, porogen, and resin binder, the porosity of porous alloy steel ceramics is 65.0%, the pore diameter is 18.2 μm, the outer layer is made of alloy steel ceramic materials, and the alloy steel ceramic materials are composed of a mass ratio of 100:85:8 alloy steel powder, ceramic powder, resin binder.

[0037] The automobile gear of the present embodiment is obtained by the following method:

[0038] Mix the alloy steel powder, ceramic powder, porogen, and resin binder with a mass ratio of 100:80:0.8:10, and press them into a core body under a pressure of 1080Mpa; the mass ratio is 100:85:8 Mix the alloy steel powder, ceramic powder, and resin binder, coat the mixed a...

Embodiment 3

[0042] The automobile gear in this embodiment includes a core body and an outer layer arranged on the surface of the core body. The core body is made of porous alloy steel ceramic material, and the porous alloy steel ceramic material is made of alloy steel with a mass ratio of 100:110:1.0:11. powder, ceramic powder, porogen, and resin binder, the porosity of porous alloy steel ceramics is 70.8%, the pore diameter is 12.3 μm, the outer layer is made of alloy steel ceramic materials, and the alloy steel ceramic materials are composed of a mass ratio of 100:100:9 alloy steel powder, ceramic powder, resin binder.

[0043] The automobile gear of the present embodiment is obtained by the following method:

[0044] Mix the alloy steel powder, ceramic powder, porogen, and resin binder with a mass ratio of 100:110:1.0:11, and press it into a core body under a pressure of 1150Mpa; the mass ratio is 100:100:9 Mix the alloy steel powder, ceramic powder and resin binder, coat the mixed al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com