Preparation method of P-phase VO2 nano-powder

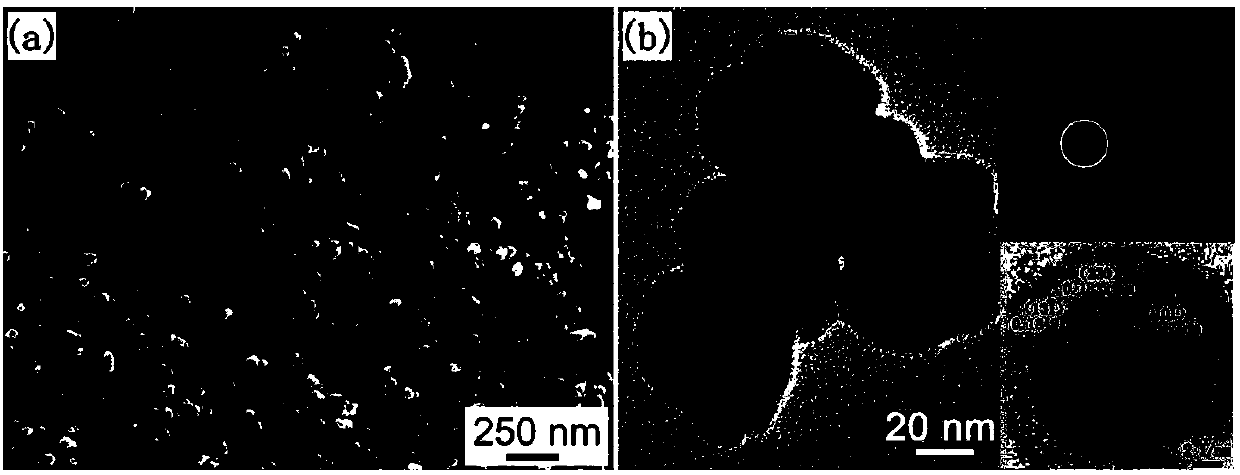

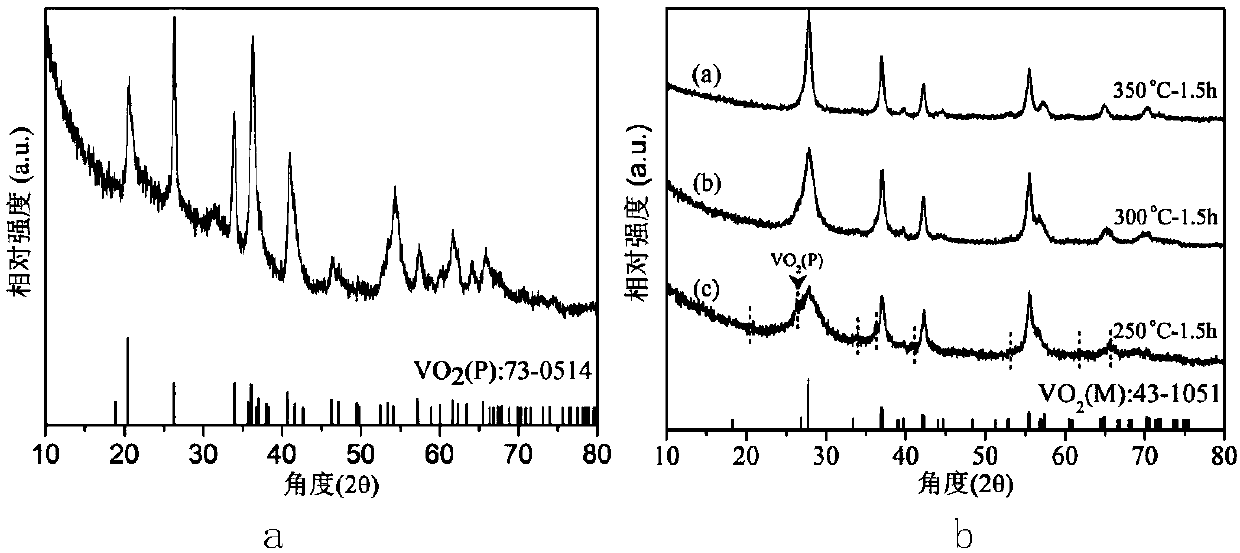

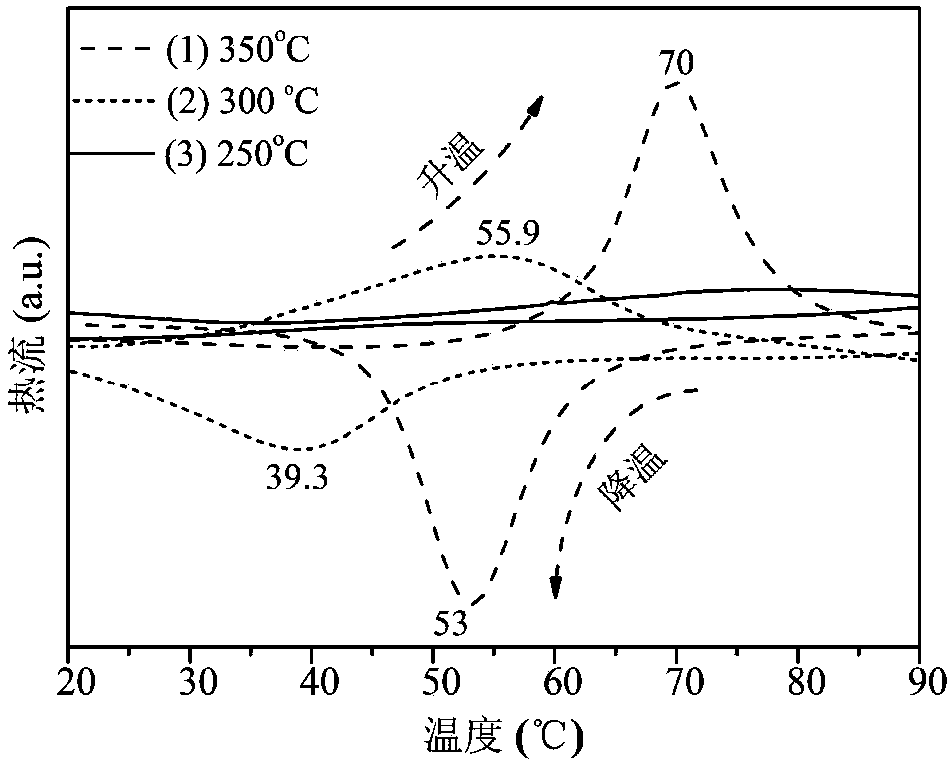

A vanadium dioxide nano-powder technology, applied in the direction of vanadium oxide, nano-technology, etc., can solve the problems of increased cost and adverse environmental impact, and achieve the effects of small size, good dispersion, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The concrete steps of preparation are:

[0030] Step 1, first according to the weight ratio of ammonium metavanadate, docusate sodium and water is 0.03:0.03:5, ammonium metavanadate and docusate sodium are added to water and stirred for 2h; wherein, water is deionized water (or distilled water) to obtain a mixed solution. Then according to the volume ratio of 80wt% formic acid solution and water in the mixed solution being 0.1:1, add the formic acid solution dropwise to the mixed solution under stirring to obtain a reaction precursor solution.

[0031] In step 2, first place the reaction precursor solution at 180° C. for a sealed reaction for 4 days to obtain a reaction solution. Carry out the processing of solid-liquid separation, washing and drying to reaction solution successively; Wherein, solid-liquid separation processing is centrifugal separation, and its rotating speed is 7000r / min, time is 10min, and washing processing is to use deionized water (or distilled w...

Embodiment 2

[0033] The concrete steps of preparation are:

[0034] Step 1, first according to the weight ratio of ammonium metavanadate, docusate sodium and water is 0.037:0.025:5, add ammonium metavanadate and docusate sodium to water and stir for 2.5h; wherein, water is deionized water (or distilled water) to obtain a mixed solution. Then, according to the volume ratio of 83wt% formic acid solution to water in the mixed solution of 0.085:1, the formic acid solution was added dropwise to the stirred mixed solution to obtain a reaction precursor solution.

[0035]In step 2, first place the reaction precursor solution at 198° C. for a closed reaction for 3 days to obtain a reaction solution. Carry out the treatment of solid-liquid separation, washing and drying to reaction solution successively; Wherein, solid-liquid separation process is centrifugation, and its rotating speed is 7750r / min, time is 9min, and washing process is to use deionized water (or distilled water) and ethanol The s...

Embodiment 3

[0037] The concrete steps of preparation are:

[0038] Step 1, first according to the weight ratio of ammonium metavanadate, docusate sodium and water is 0.044:0.02:5, ammonium metavanadate and docusate sodium are added to water and stirred for 3h; wherein, water is deionized water (or distilled water) to obtain a mixed solution. Then, according to the volume ratio of 85wt% formic acid solution to water in the mixed solution of 0.065:1, the formic acid solution was added dropwise to the stirred mixed solution to obtain a reaction precursor solution.

[0039] In step 2, first place the reaction precursor solution at 216° C. for a closed reaction for 3 days to obtain a reaction solution. Carry out the treatment of solid-liquid separation, washing and drying to reaction solution successively; Wherein, solid-liquid separation process is centrifugation, and its rotating speed is 8500r / min, time is 7min, and washing process is to use deionized water (or distilled water) and ethanol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com