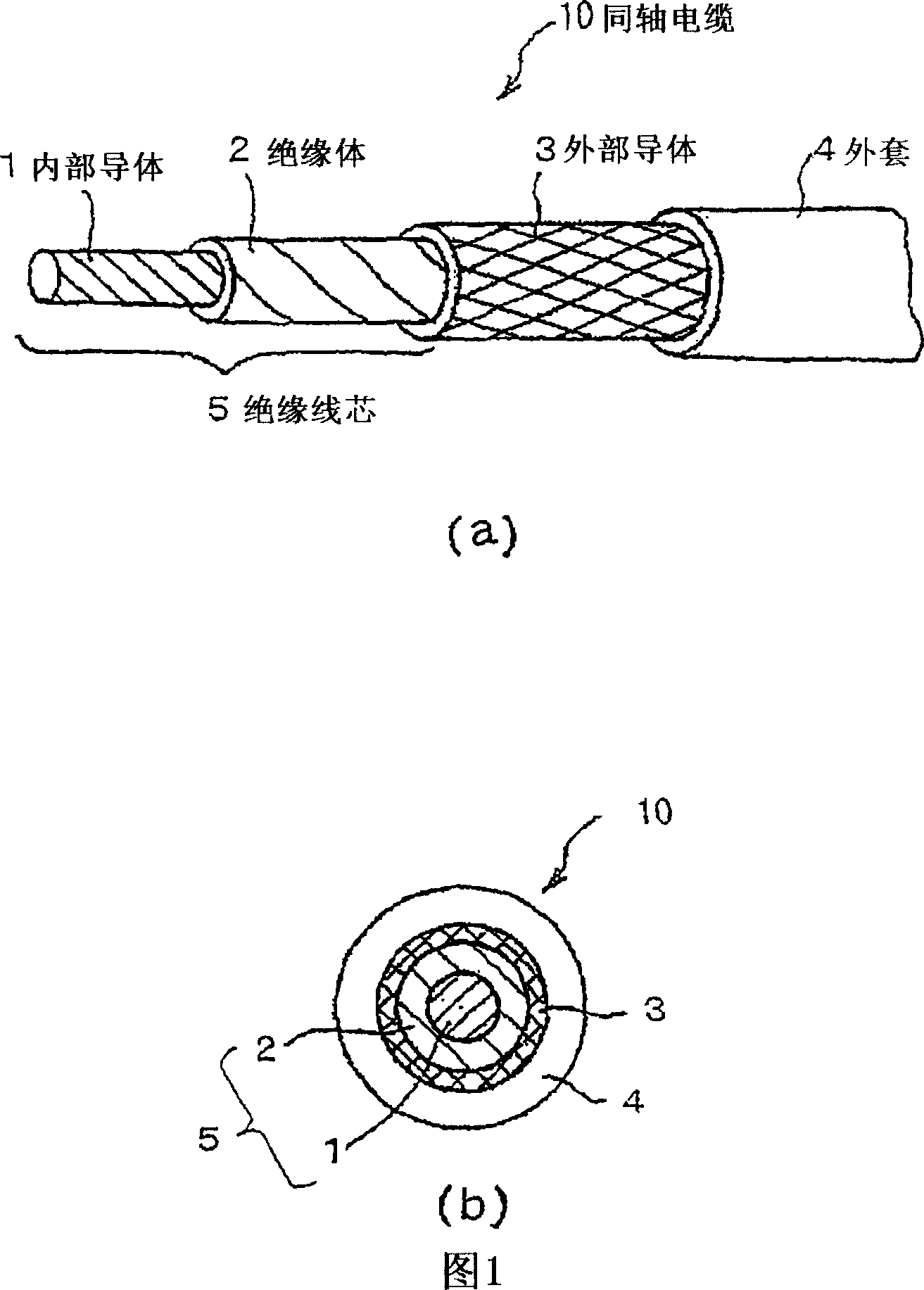

High-precision foamed coaxial cable

A coaxial cable, high-precision technology, applied in the direction of coaxial cable/analog cable, cable insulation structure, etc., can solve the problem that it is difficult to realize coaxial cable, etc., and achieve the effect of reducing the change of characteristic impedance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

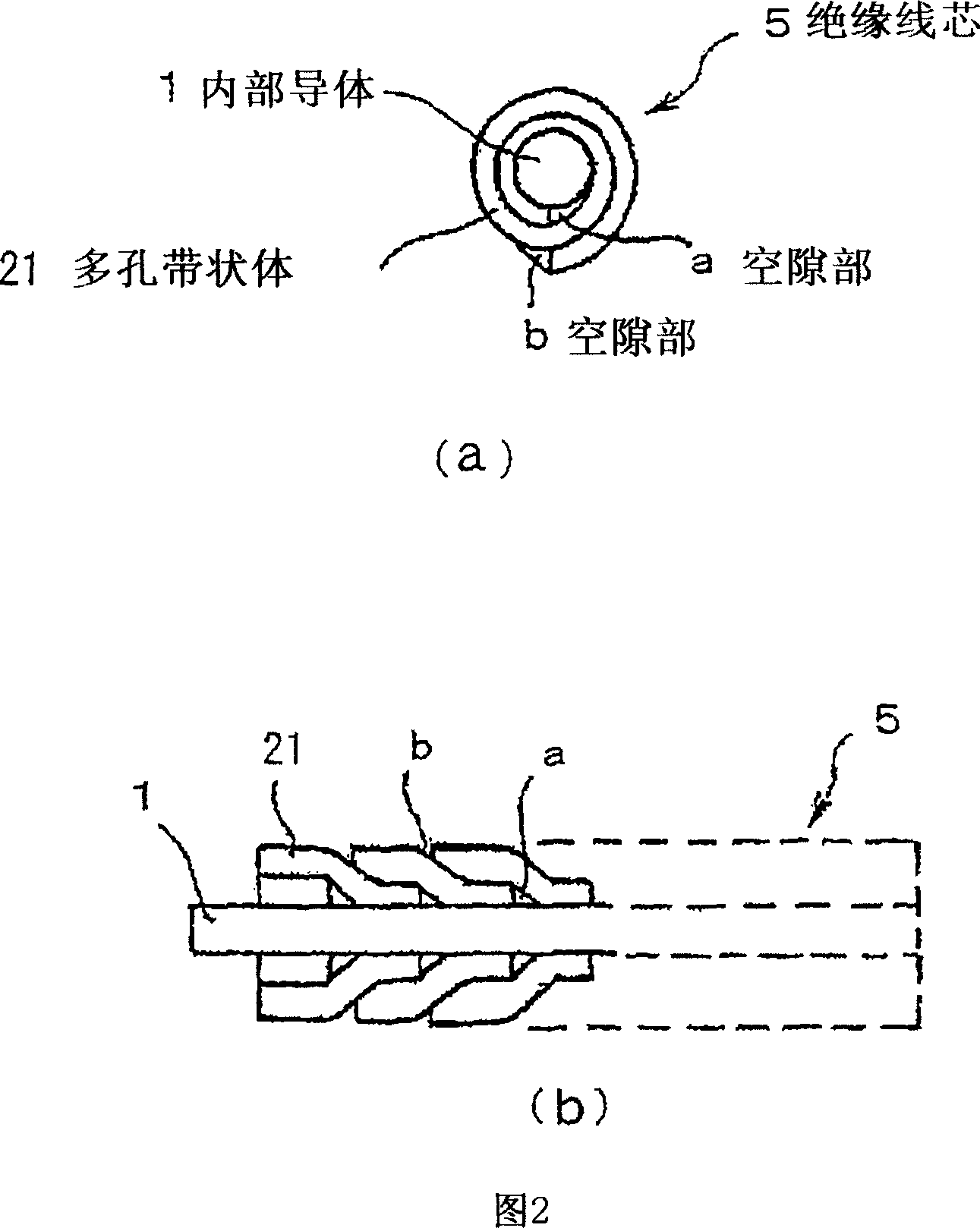

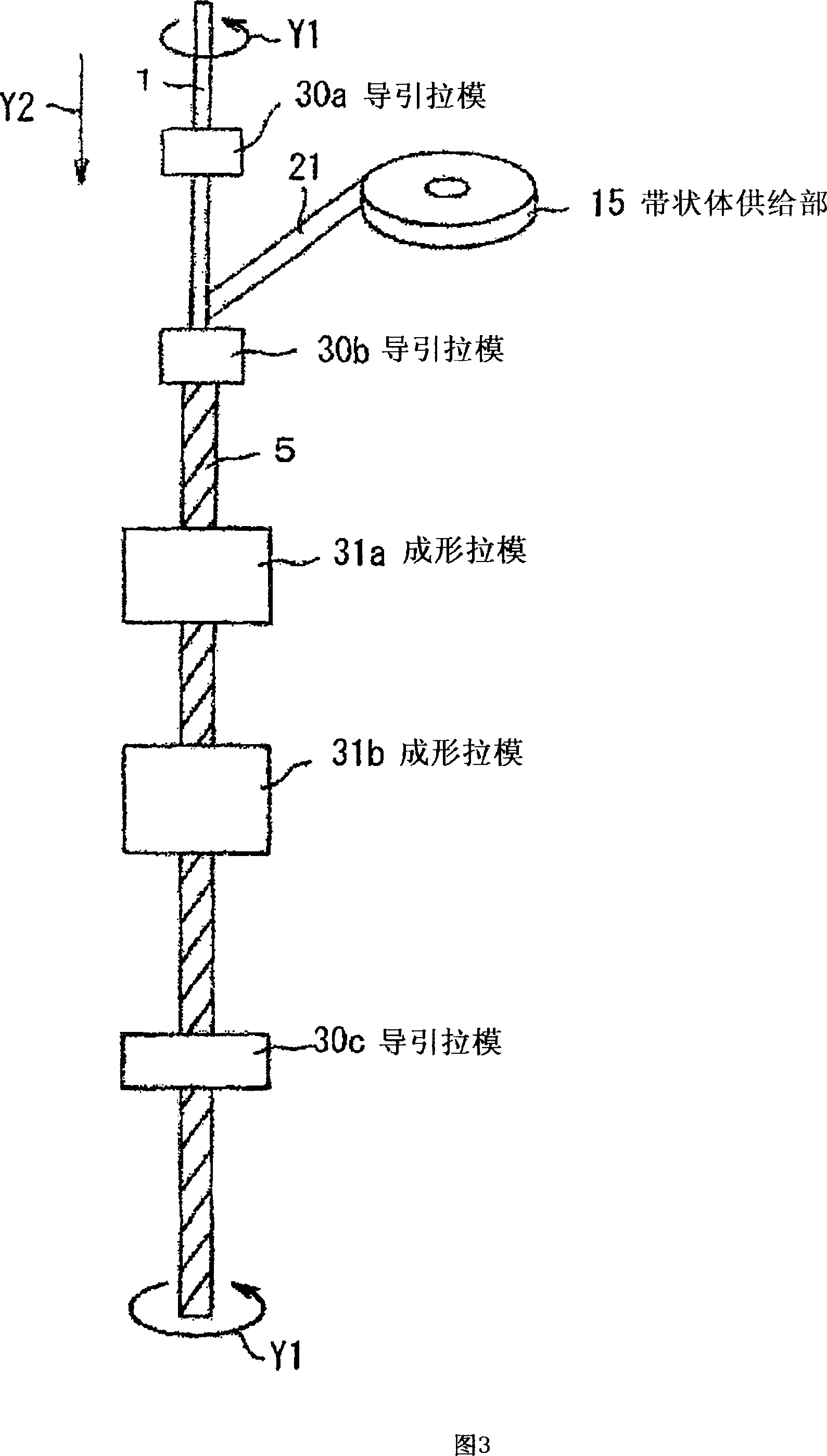

[0075] By the method described in the embodiment of the present invention, the reduction ratio (compression ratio) of the outer diameter of the insulator 2 was changed, the insulated core 5 was molded, and the variation in the outer diameter of each insulated core 5 was studied. The inner conductor 1 is a conductor obtained by twisting seven annealed copper wires plated with silver plating with a thickness of 1 μm and an outer diameter of 0.16 mm. The outer diameter accuracy of the silver-plated annealed copper wires is 2 / 1000 mm or less. The porous strip-shaped body 21 uses a material with a porosity of 80%, so that the winding angle of the strip-shaped body is 80 degrees, and the winding tension is 0.70kg / mm 2 . The results are shown in Table 1.

[0076] Insulator outer diameter compressibility (%)

[0077] When the compressibility (10%) of the outer diameter of the insulator 2 is increased, the tensile force when passing through the forming drawing die when the s...

Embodiment 2

[0079] Using the method described in the embodiment of the present invention, the coaxial cable 10 was formed by changing the penetration rate of the braid into the insulator 2 (insulated core 5), and the braid outer diameter and characteristic impedance value of each coaxial cable 10 were studied. deviation. The results are shown in Table 2. The braided wire used for the braid is a silver-plated annealed copper wire with a thickness of 1 μm and a tin alloy (0.75% copper) plating with a thickness of 0.5 μm. The variation in the characteristic impedance value was measured using the TDR measurement method, and the standard deviation was obtained.

[0080] Biting rate of braid (%)

[0081] By increasing the biting rate of the braid, the insulator and the braid can be integrated, the circularity of the braid can be improved, and the deviation of the characteristic impedance value can be reduced. However, if the bite rate is set to 35% or more, the frictional resistance...

Embodiment 3

[0083] Using the method described in the embodiment of the present invention, the coaxial cable 10 is shaped by changing the biting rate of the braid into the insulator 2 (insulated core 5) and the type of plating of the braided wire, and each coaxial cable 10 is examined. The changes in the characteristic impedance value (bend test) and the flexibility of the coaxial cable 10 (flexibility test) when a core rod with a diameter of Φ5 is wound five turns. The results are shown in Table 3. The braided wire used for the braid is a silver-plated annealed copper wire plated with a silver film with a thickness of 1 μm, and a silver-plated annealed copper wire with a thickness of 1 μm is plated with a tin alloy (0.75% copper) plating with a thickness of 0.5 μm. Annealed copper wire with double plating.

[0084] The bending test measures the characteristic impedance value (A) of a cable cut to 500mm. The central part of the cable is about 200mm wrapped around a core rod with an outer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com