Peptidoglycan immunopotentiator and its production process

An immunopotentiator and production method technology, applied in pharmaceutical formulations, peptide/protein components, animal feed, etc., can solve the problems of immature technology, high cost, and large difference in product batch quality, and achieve a wide range of applications, The effect of low production cost and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

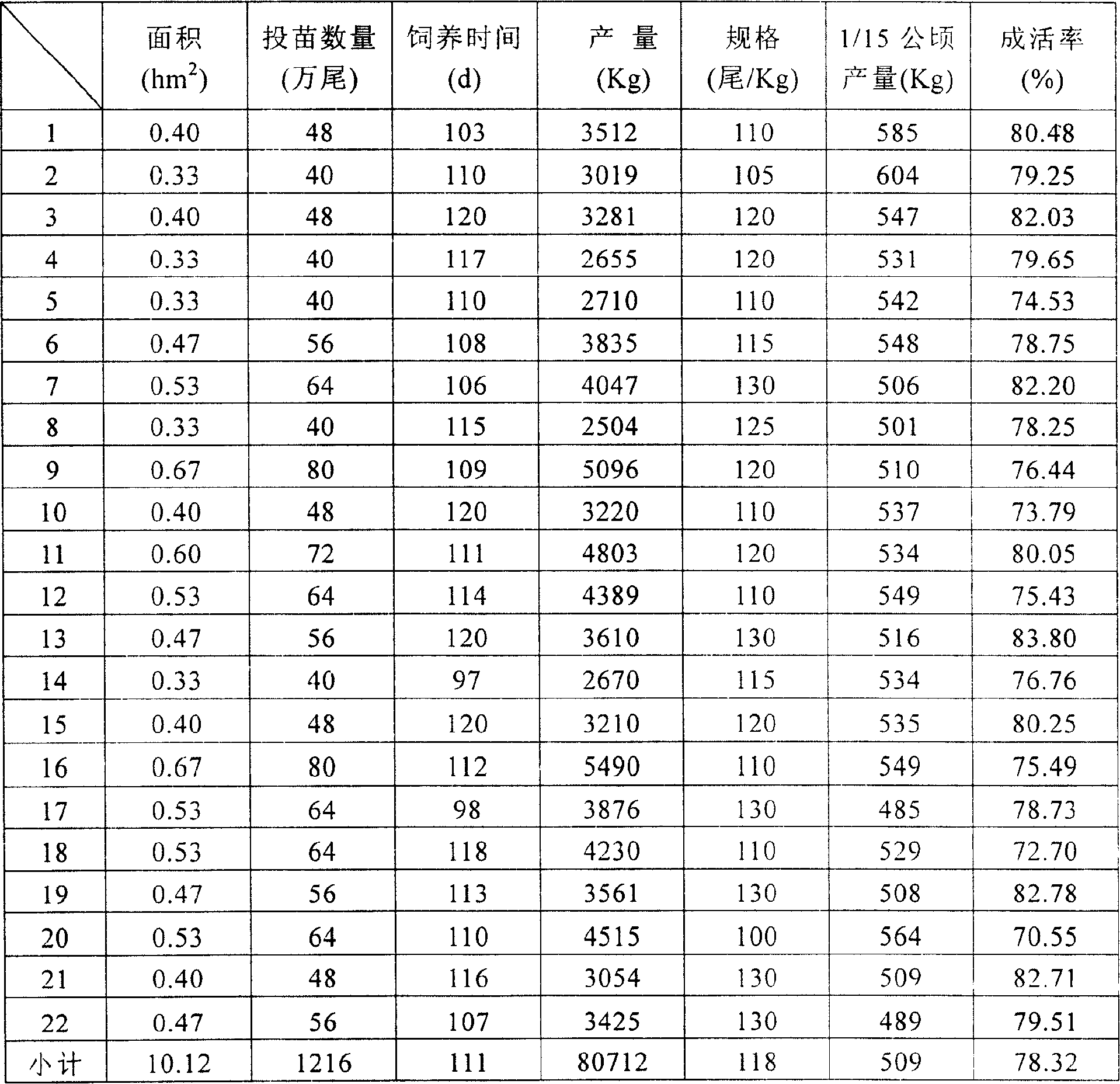

[0017] The production and application effect of peptidoglycan preparation for the cultivation of prawn seedlings:

[0018] In the embodiment of the present invention, the main equipment conditions used are a 250-liter fermenter with a total volume of 250 liters and a working volume of 240 liters. The components of the fermentation broth used contained 1% glucose, 1% lactose, 1% tryptone, 0.6% yeast extract, 0.6% beef extract, 0.1% Tween-80, 1% Na 2 HPO 4 , 0.6% KH 2 PO 4 and 0.05% MgSO 4 , pH6.5.

[0019] Take 1 bottle of freeze-dried powder of Bifidobacterium thermophilum stored at -70°C, which is selected from Bifidobacterium thermophilum, Bifidobacterium bifidum, or Bifidobacterium adolescent Bifidobacterium adolescentis, or Bifidobacterium infantis, or Bifidobacterium longum. After being activated by the slant medium, select a single colony and inoculate it in the liquid medium, and after culturing at 37°C for 24 hours, expand the culture to form a seed liquid. When ...

Embodiment 2

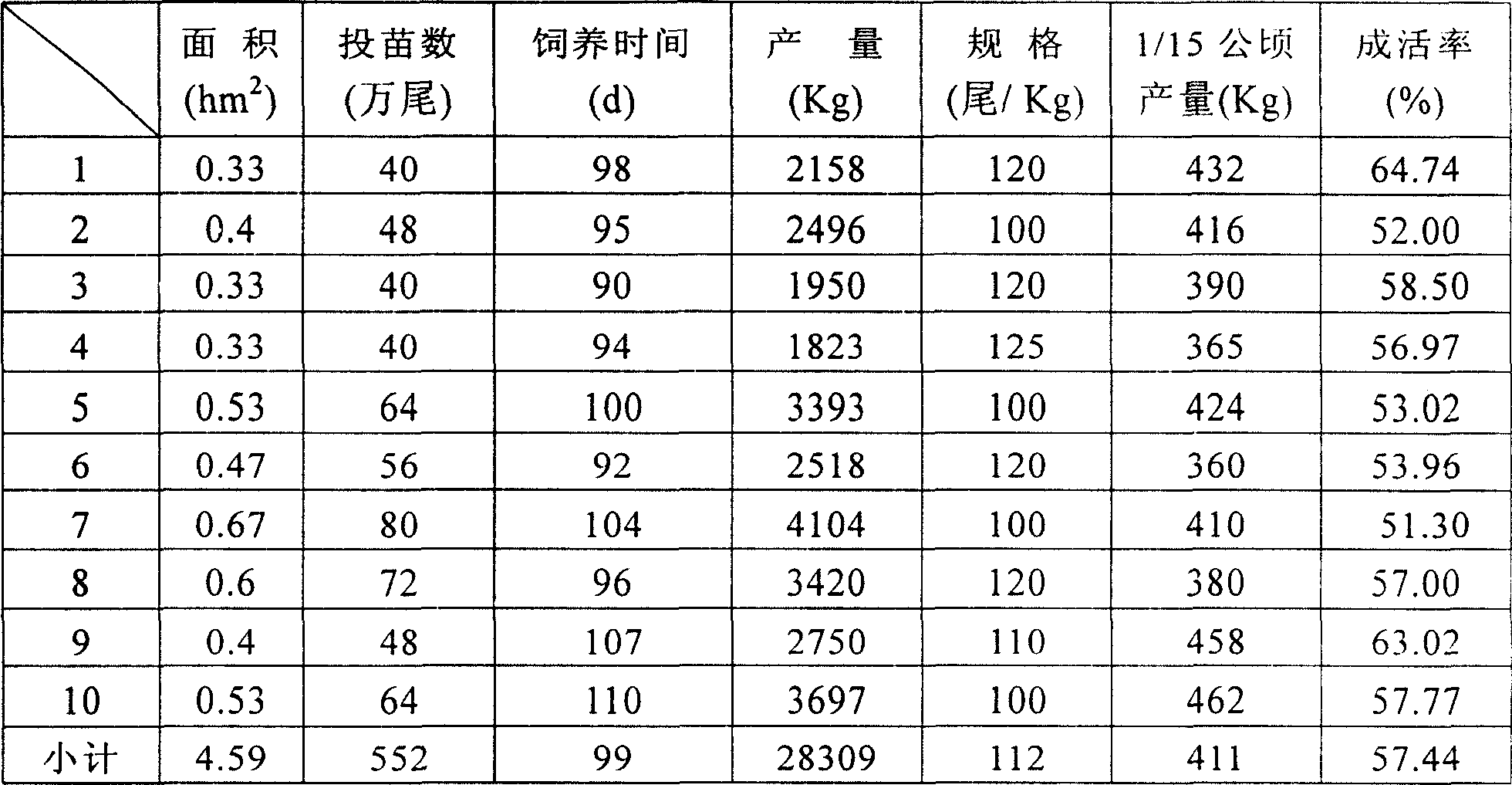

[0024] Production and application effect of peptidoglycan immune enhancer for turbot indoor cement pond culture:

[0025] This example is carried out in the same steps as in Example 1, except that the fermentation is terminated after 24 hours of fermentation, nitrogen is introduced into the tank, and the fermentation pressure is reached to two secondary fermentation tanks with a volume of 1000 liters, and each tank is inoculated The content is 12.5%, and the secondary fermentation is carried out. Finally, an immune enhancer with the following physical and chemical parameters is obtained: color: light brown liquid, viscosity: 4.2, specific gravity: 1.030; the immune enhancer contains: peptidoglycan with a relative molecular weight of less than 20KD as an active ingredient according to the W / V ratio: 1.8%, protein with molecular weight less than 20KD: 6%, fat: 0.4%, ribonucleic acid: 0.015%, total solid content: 9%; the rest: water; about 16kg (calculated by the weight of wet ba...

Embodiment 3

[0031] The production and application effect of peptidoglycan preparation for Penaeus vannamei culture production:

[0032] This example is carried out by basically the same steps as in Example 1, except that while the first fermenter is fermenting, the mixed fermentation liquid is injected into another 5-ton fermenter, heated and pressurized to 0.07KPa / 106 Sterilize at ℃ for 20 minutes; turn off all air switches, and connect the nitrogen pipe directly to the air intake end of the air filter; when the pressure in the fermenter drops to 0.02KPa, start feeding nitrogen into the fermenter to maintain positive pressure; the temperature in the fermenter drops When it reaches 37°C, it can be connected to the fermented liquid that has been fermented in the first fermenter; the culture conditions after inoculation, the separation and digestion of the bacteria are the same as in Example 1, and finally obtain the following physical and chemical parameters: color: light brown Liquid, vis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com