Method for preparing high molecular weight cation type polyacrylamide

A polyacrylamide and cationic technology, which is applied in the field of preparing high molecular weight cationic polyacrylamide, can solve the problems of low cationic degree, inability to meet difficult wastewater treatment, and low molecular weight, so as to improve conversion rate and reduce molecular crossover. Linkage probability, solubility improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below:

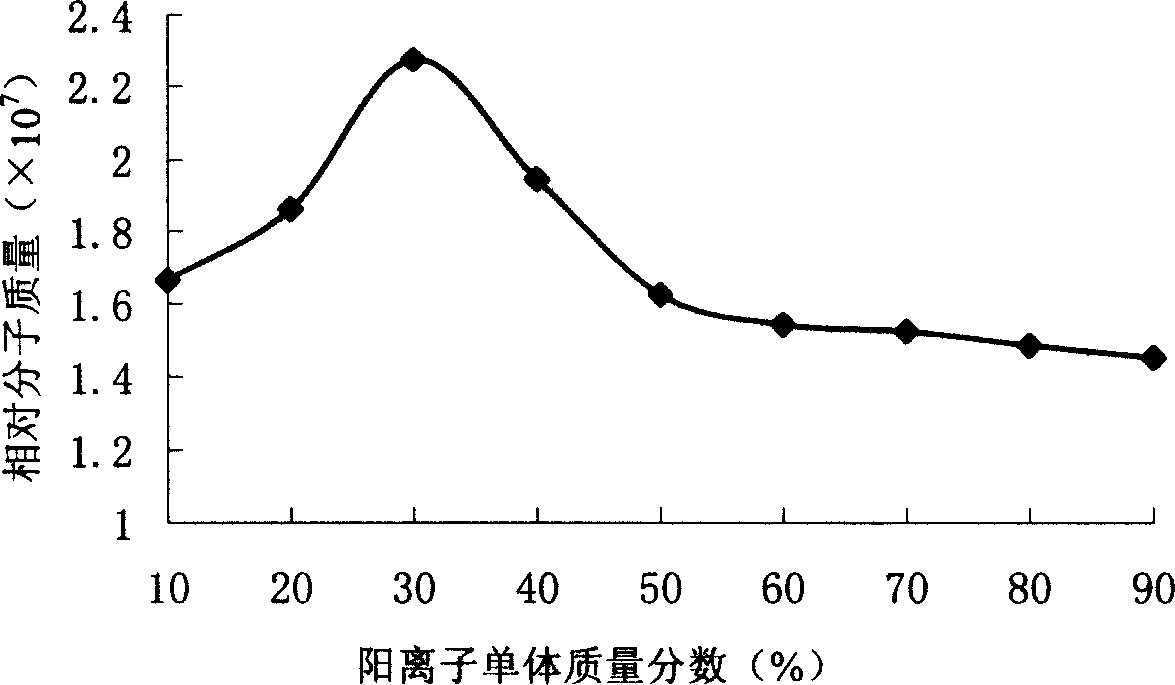

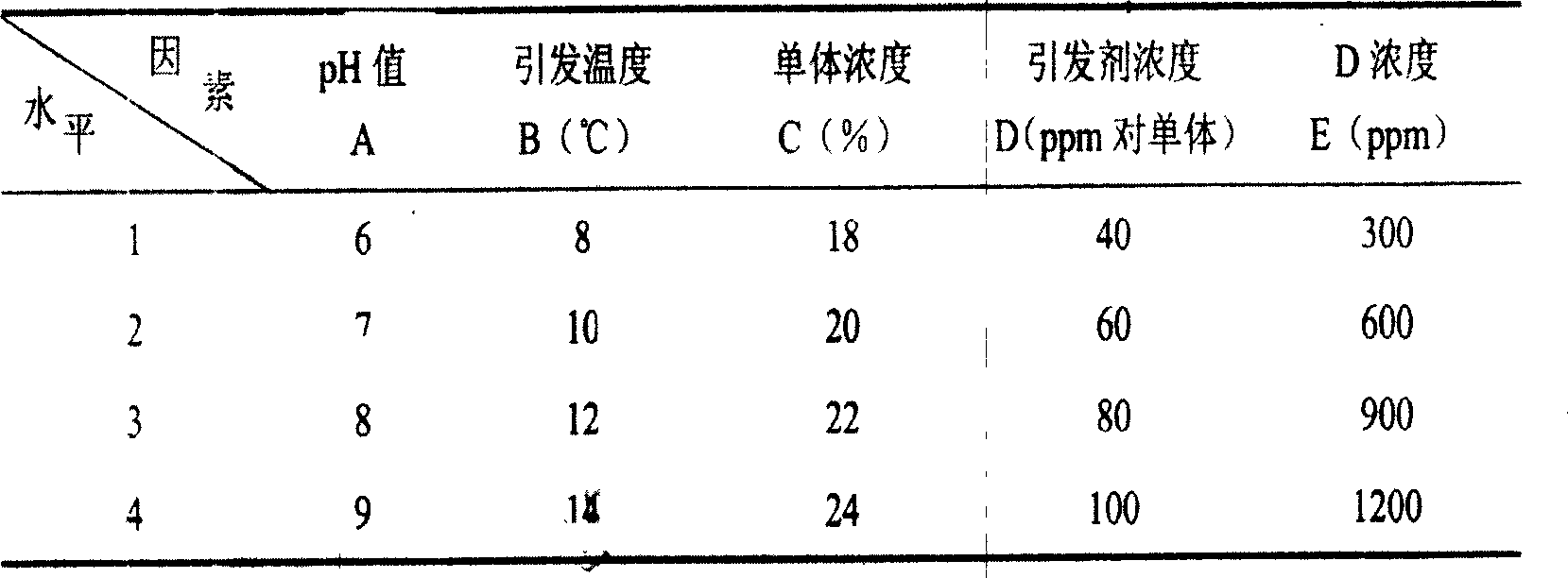

[0008] This invention selects 5 factors that have a greater impact on the relative molecular weight of the polymer, as shown in Table 1, through the method of orthogonal experiment, find out the best test conditions, the experiment process is: acrylamide and acryloyloxyethyl Trimethylammonium chloride is mixed in a weight ratio of 8:2, added to the reactor, injected with deionized water and stirred to dissolve to a solution with a total monomer concentration of 20% to 30%; adjust the pH value of the system to 6 to 9 with ammonia water ; Add chain extender, reducing agent, disodium ethylenediaminetetraacetic acid, urea, Span-20 and azobisisobutyronitrile in sequence to the reaction kettle with an initiation temperature of 8°C to 14°C, stir and mix well; After 30 minutes of nitrogen deoxygenation, add an oxidizing agent, in which chain extender, reducing agent, disodium edetate, urea, Span-20, azobisisobutyronitrile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com