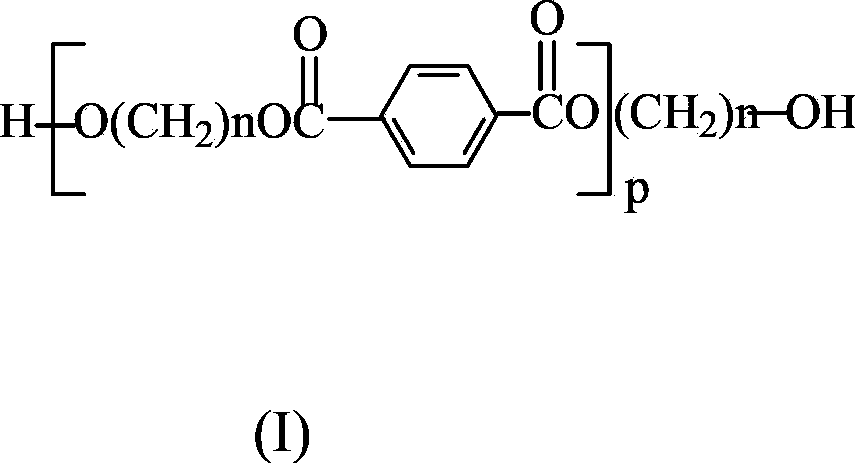

Biodegradable aliphatic-aromatic block mixed polyester preparation method

A mixed polyester, biodegradable technology, applied in the field of preparation of biodegradable aliphatic-aromatic block mixed polyester, can solve the problems of aggravation, incomplete reaction, low reactivity of terephthalic acid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

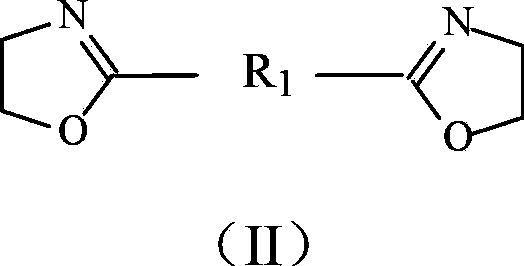

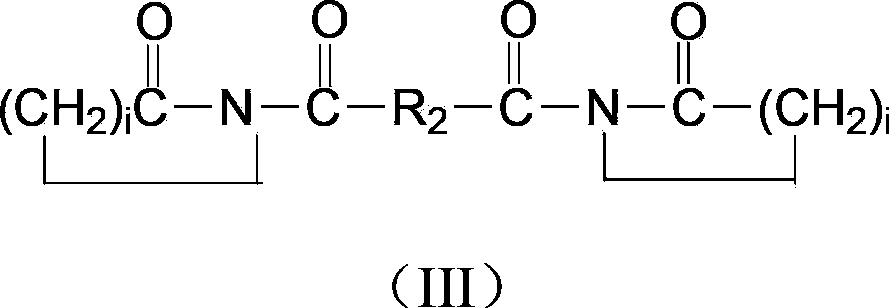

Method used

Image

Examples

Embodiment 1

[0035] 1) Preparation of aliphatic-aromatic block mixed polyester prepolymer: take by weight 20 parts of dimethyl terephthalate, 29.69 parts of 1,4-butanediol, 0.10 part of stannous chloride , 0.10 parts of phosphorous acid, 0.14 parts of tetrabutyl titanate, after reacting at 160°C for 4 hours, gradually raise the temperature to 200°C, when the amount of methanol evaporated reaches the theoretical value, gradually raise the temperature to 240°C to remove excess unreacted 1, 4-butanediol; then lower the temperature to 180°C, add 16.56 parts of adipic acid, continue the reaction for 4 hours, then gradually raise the temperature to 200°C; finally use a decompression device, first use a water pump to depressurize gradually for 3 hours, and then use an oil pump Reduce the pressure to 2mmHg and react for 2 hours to obtain a polyterephthalic acid-adipate-butylene glycol ester prepolymer with an intrinsic viscosity of 0.36dL / g, an acid value of 118.83mgKOH / g, and a hydroxyl value of 3...

Embodiment 2

[0038] 1) Preparation of PrePBAT prepolymer: Weigh 20 parts of dimethyl terephthalate, 29.69 parts of 1,4-butanediol, 0.10 part of stannous chloride, 0.10 part of phosphorous acid, 0.14 part of titanium in parts by weight After reacting at 160°C for 4 hours, gradually raise the temperature to 200°C. When the amount of methanol evaporated reaches the theoretical value, gradually raise the temperature to 240°C to remove excess unreacted 1,4-butanediol; then cool down to 180°C, add 13.55 parts of adipic acid, continue to react for 4 hours, then gradually raise the temperature to 200°C; finally use a water pump to gradually reduce the pressure for 3 hours, and then use an oil pump to reduce the pressure to 2mmHg and react for 2 hours to obtain an intrinsic viscosity of 0.35dL / g, a PrePBAT prepolymer with an acid value of 107.65 mgKOH / g and a hydroxyl value of 22.95 mgKOH / g.

[0039] 2) Weigh 6.15 parts of PrePBAT prepared in step 1), 1.07 parts of 1,4-phenyl-bis(2-oxazoline), 0.0...

Embodiment 3

[0041] 1) Preparation of PrePBAT prepolymer: Weigh 20 parts of dimethyl terephthalate, 29.69 parts of 1,4-butanediol, 0.10 part of stannous chloride, 0.10 part of phosphorous acid, 0.14 part of titanium in parts by weight Under the protection of a nitrogen atmosphere, react at 160°C for 4 hours, then gradually raise the temperature to 200°C, and when the amount of methanol evaporated reaches the theoretical value, gradually raise the temperature to 240°C to remove excess unreacted 1,4- Butanediol; then lower the temperature to 180°C, add 10.54 parts of adipic acid, continue the reaction for 4 hours, then gradually raise the temperature to 200°C; finally use a water pump to gradually reduce the pressure for 3 hours, and then use an oil pump to reduce the pressure to 2mmHg for 2 hours. A PrePBAT prepolymer having an intrinsic viscosity of 0.42 dL / g, an acid value of 71.35 mgKOH / g, and a hydroxyl value of 2.78 mgKOH / g was obtained.

[0042] 2) Weigh 5.44g parts of PrePBAT prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com