Organic acid super roughening process for pretreatment of printed circuit board resistance welding film layer

A printed circuit board, organic acid technology, applied in the secondary treatment of printed circuits, printed circuits, printed circuit manufacturing, etc., can solve problems such as scrapping, solder mask layer peeling, etc., to achieve a wide source of raw materials, avoid falling off, strengthen The effect of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

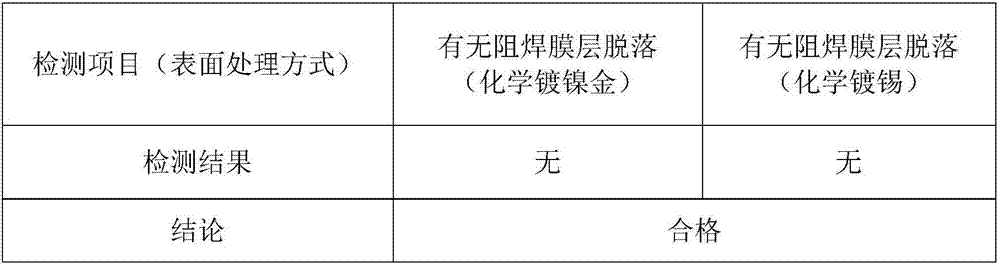

Embodiment 1

[0015] Drain the working liquid in the pretreatment tank of the solder mask layer of the printed circuit board completely, rinse it with tap water, and continue to circulate and clean it with deionized water for 30 minutes. Prepare 1 liter of organic acid super-coarsening agent aqueous solution, wherein the organic acid super-coarsening agent includes 40 grams of copper chloride, 100 milliliters of acetic acid, 50 grams of sodium acetate, 10 grams of guanidine hydrochloride, 1 gram of aminotriazole and 10 milliliters of triethanolamine , at this time, the pH of the aqueous solution of the organic acid super-coarsening agent is 2.0, and the specific gravity is 1.11g / cm 3 . Add 1 liter of organic acid super-roughening agent aqueous solution to the pre-treatment tank of the solder mask layer of the printed circuit board, heat the pre-treatment tank of the solder mask layer of the printed circuit board to 25°C, and start the circulating filter pump; Put the circuit board of the s...

Embodiment 2

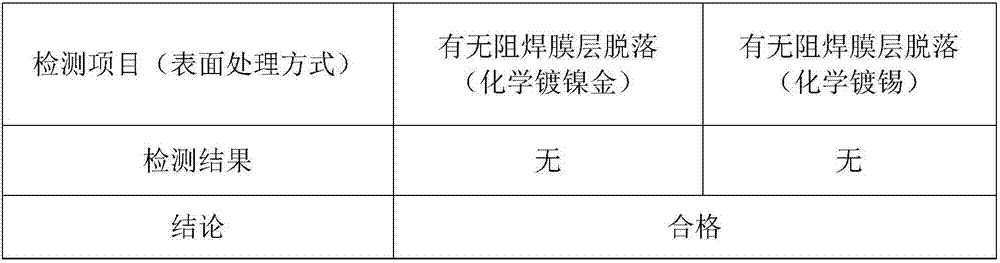

[0020] Drain the working liquid in the pretreatment tank of the solder mask layer of the printed circuit board completely, rinse it with tap water, and continue to circulate and clean it with deionized water for 30 minutes. Prepare 1 liter of organic acid super-coarsening agent aqueous solution, wherein the organic acid super-coarsening agent includes 80 grams of copper chloride, 150 milliliters of acetic acid, 80 grams of sodium acetate, 30 grams of guanidine hydrochloride, 3 grams of aminotriazole and 30 milliliters of triethanolamine , at this time, the pH of the aqueous solution of the organic acid super-coarsening agent is 4.0, and the specific gravity is 1.16g / cm 3 . Add 1 liter of organic acid super-roughening agent aqueous solution to the pre-treatment tank of the solder mask layer of the printed circuit board, heat the pre-treatment tank of the solder mask layer of the printed circuit board to 35°C, and start the circulating filter pump; Put the circuit board of the ...

Embodiment 3

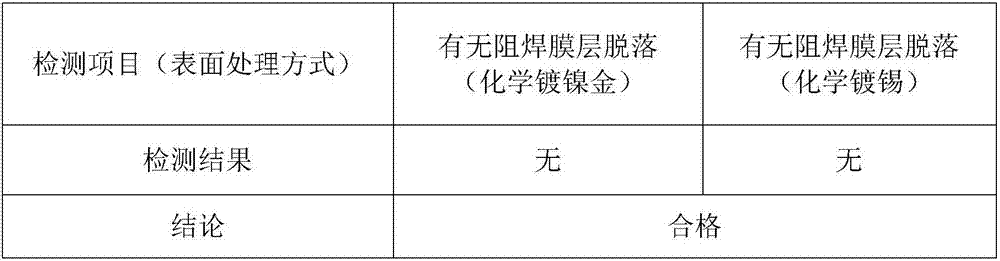

[0025] Drain the working liquid in the pretreatment tank of the solder mask layer of the printed circuit board completely, rinse it with tap water, and continue to circulate and clean it with deionized water for 30 minutes. Prepare 1 liter of organic acid super-coarsening agent aqueous solution, wherein the organic acid super-coarsening agent includes 60 grams of copper chloride, 130 milliliters of acetic acid, 70 grams of sodium acetate, 20 grams of guanidine hydrochloride, 2 grams of aminotriazole and 20 milliliters of triethanolamine , at this time, the pH of the aqueous solution of the organic acid super-coarsening agent is 3.0, and the specific gravity is 1.14g / cm 3 . Add 1 liter of organic acid super-roughening agent aqueous solution to the pre-treatment tank of the solder mask layer of the printed circuit board, heat the pre-treatment tank of the solder mask layer of the printed circuit board to 30°C, and start the circulating filter pump; Put the circuit board of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com