Waterborne superhydrophobic coating for building exterior walls, and preparation method and application thereof

A technology for super-hydrophobic coatings and building exterior walls, applied in building insulation materials, anti-fouling/underwater coatings, building components, etc., can solve the problems of complex formulas and coatings that are not super-hydrophobic, and achieve simple preparation processes and good super-hydrophobic properties. Hydrophobic performance, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) 1g SiO 2 (Zhejiang Wanjing New Material Co., Ltd., SP-30, average particle size 30nm, the same below) was added to 30mL of water, and mixed evenly under magnetic stirring, and then 2.5g of silicone emulsion (Shanghai Xianglan Chemical Co., Ltd., ESASIL 505, with a solid content of about 50%) and 1 mL of polyfluoroacrylic resin (Taicang Sinochem Environmental Protection Chemical Co., Ltd., EG616G), and stirred evenly to obtain a superhydrophobic coating.

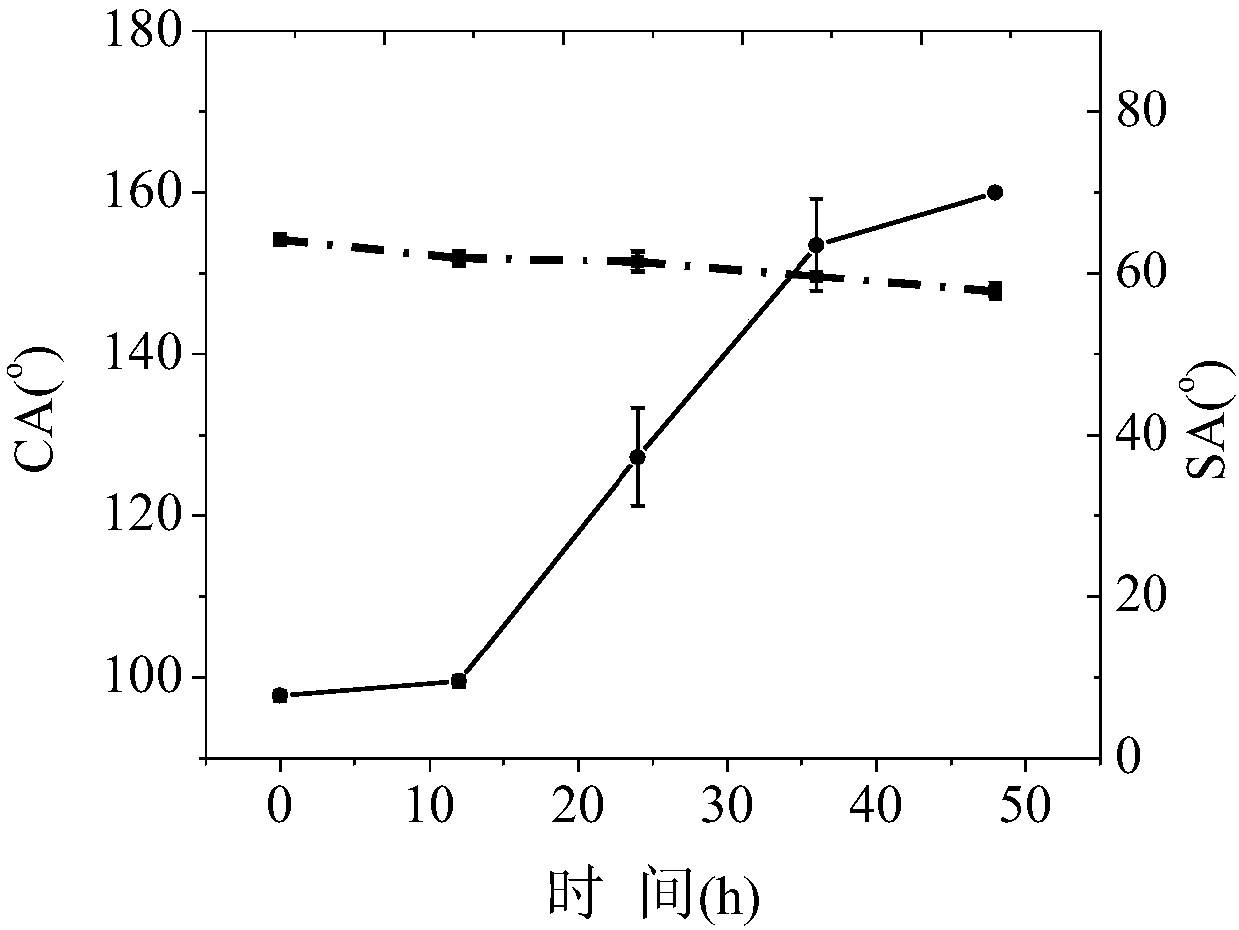

[0023] (2) Spray the superhydrophobic coating on the glass surface, dry and solidify at 120°C for 20min to form a superhydrophobic coating ( figure 1 ), the static contact angle is 154.2°, and the rolling angle is 6.1°. Other properties are with embodiment 1. After immersing the coating in deionized water, it was found that after 12 hours, the contact angle of the coating still reached 147.7°, the rolling angle was less than 10°, and it still had super-hydrophobic properties (in practical applications, it is rare...

Embodiment 2

[0027] (1) 2g CaCO 3 (1200 mesh, heavy calcium, generally commercially available) was added to 10mL of water, and mixed evenly under stirring, then 1g of silicone emulsion (Shanghai Xianglan Chemical Co., Ltd., ESASIL 505, solid content about 50%) and 1mL containing Fluoroacrylic acid emulsion (Taicang Sinochem Environmental Protection Chemical Co., Ltd., EG616G) was stirred evenly to obtain a superhydrophobic coating.

[0028] (2) Brush the superhydrophobic coating on the glass surface, dry and cure at 120°C for 20 minutes to form a superhydrophobic coating. The static contact angle is 154.4°, and the rolling angle is 9.6°. When the coating is immersed in deionized water, the contact angle and rolling angle basically do not change within 10 hours. Coating mechanics and self-cleaning properties are the same as in Example 1.

Embodiment 3

[0030] (1) 5g CaCO 3 (2000 mesh, light calcium, generally commercially available) was added to 50mL of water, and mixed evenly under stirring conditions, then added 5g of acrylic latex paint (Youtubao durable exterior wall paint, Shanghai Bauhinia Paint Co., Ltd.) and 2.5mL fluorine-containing acrylic emulsion (same as above), stirred evenly to obtain a super-hydrophobic coating.

[0031] (2) Apply the superhydrophobic coating onto the surface of the glass / aluminum plate by dripping or brushing, and dry and cure at 120°C for 20 minutes to form a superhydrophobic coating with a static contact angle of 156.4° and a rolling angle of 10°. Coating mechanics and self-cleaning properties are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Static contact angle | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com